Caveat Lector! Reader beware!

I hesitate to even tread down my chosen path of discussion because what I need to say is surrounded by a very bad word: a dirty, vile, detested word amongst a certain group of people.

It’s a word that conjures up images of burning history books and stomping on flags, if there was a flag that could possibly surmount and contain such a diverse group as the WIS.

Okay, maybe it isn’t that bad; but many watch lovers and horology nerds alike have been known to scoff at this very word as if it signals the end of a serious conversation.

What word is this? Some of you have surely already guessed it: quartz.

HOLD ON, hold on, just grab that paper bag and take a few deep breaths! In and out.

Feeling better? Good.

You mustn’t worry, your friendly neighborhood nerdwriter isn’t headed down the assumed road this time. I’ll admit that I was pulling your leg just a bit: I’m not going to talk about a quartz watch (though without continued interest in quartz watches the entire industry may have faded away, but that’s a story for another day).

I’m actually going to talk about quartz the mineral, comprised of oxygen and silicon, which is the second most abundant mineral on earth.

Of course, the reason I need to discuss quartz in the first place is thanks to a pretty increditastic watch from Richard Mille, the RM 011 Red TPT Quartz Automatic Flyback Chronograph.

Technical beginnings

The RM 011 Red TPT Quartz Automatic Flyback Chronograph is the second use of TPT Quartz after the RM 27-02 Tourbillon Rafael Nadal, which was the basis for the development of TPT Quartz (see Richard Mille RM 27-02 For Rafael Nadal: The Quintessential Sports Tourbillon).

The NTPT carbon composites that came before at Richard Mille were the original drivers of development, and North Thin Ply Technologies, the company behind NTPT carbon, became an ongoing development partner.

Material science nerd alert: technical details ahead!

First things first, what is TPT?

TPT, which stands for thin ply technology, is a method for making ultra-thin unidirectional strand sheets of carbon fibers. The sheets aren’t just fibers however, they are “tapes” that are pre-impregnated (“prepreg”) with resin for more accurate and controllable application in use.

The resin is the material that works like a glue to hold the carbon fibers together; when placed under heat and pressure the resin flows between all the fibers and finally hardens to create the solid carbon fiber material we are familiar with.

The TPT carbon tapes used in Richard Mille cases have layers that are, on average, around 45 microns thin, or just under two-thousandths of an inch (.002”). Moving on to TPT Quartz, the construction is the same, only it is composed not of carbon fibers, but of fused quartz fibers. These fibers start out life as purified ground quartz crystals. These crystals are fused with heat and pressure to create fused quartz rods. These rods are then drawn (pulled and squished) under an oxy-hydrogen flame to create extremely long continuous fibers of fused quartz.

North Thin Ply Technologies developed the TPT Quartz in collaboration with Saint-Gobain Quartz, who supplied the Quartzel™ 9- or 4-micron quartz fiber filament (which is thinner than human hair); Reichhold, suppliers of ADVALITE™, a monomer-free vinyl hybrid resin; and, of course, Richard Mille, who led design and validation for the new process. The result was the world’s first thin-ply quartz fiber prepreg material, which immediately won the JEC World 2016 Innovation Award.

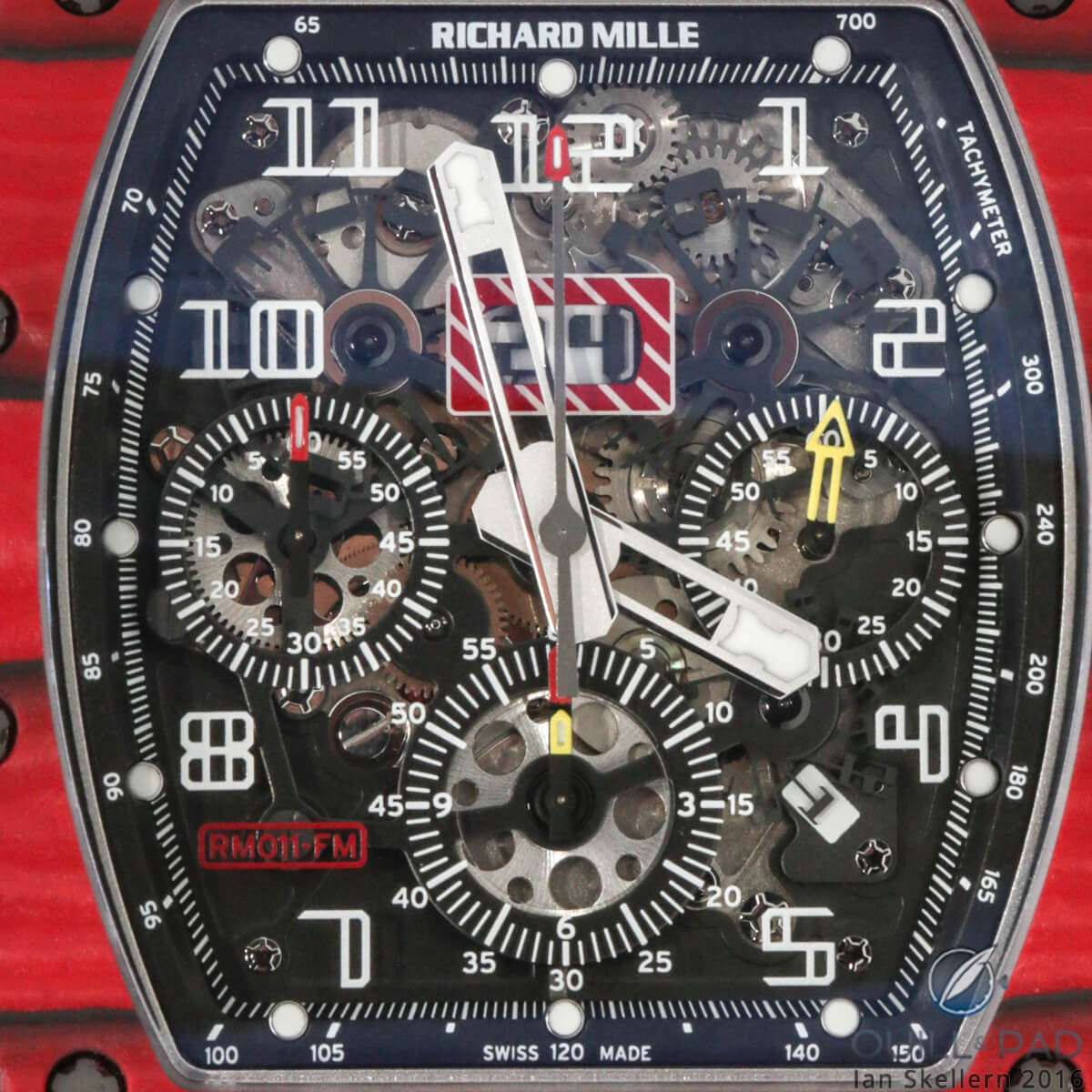

A close look at the dial side of the Richard Mille RM 011 Red TPT Quartz Automatic Flyback Chronograph

Turn it into a watch

Now that a whole slew of engineers worked together to create an entirely new material, the next step was turning it into a watch case. To achieve the desired look, the case is not entirely TPT Quartz but instead interspersed with layers of NTPT carbon because, due to the nature of quartz fibers being more flexible than carbon fibers, this played the dual role of maintaining rigidity while increasing the aesthetic impact.

The construction process begins with an automated machine laying thin layers of quartz fibers and carbon fibers in a single direction, varying each layer by 45 degrees to the previous layer. This change in direction, when multiplied over hundreds of layers, creates a nearly homogenous material that is equally strong in every direction.

For the most extreme aerospace and automotive applications, the automated dispensing machine has the ability to align the layers down to just one degree of rotation.

The layers are repeated until 600 layers have been aligned and applied, at which time the approximately 25-millimeter (one-inch) thick sheet is cured in an autoclave (a heated pressure vessel) at 120 degrees Celsius (248 degrees Fahrenheit) and a pressure of 6 bar (87 psi) to produce a very strong solid block. This rough stock is then delivered to Richard Mille’s case factory Proart, where the case components can be CNC-machined from the TPT Quartz block.

Thanks to the flat layers of the NTPT carbon and TPT Quartz and the curved shapes of the RM 011 case, the layers become exposed at different points when machined, just like stratified rock layers in the Grand Canyon. This is actually one of the most difficult aspects to deal with in a technical sense while being the coolest-looking feature of the TPT Quartz.

As the layers are exposed at an angle, they are at a much higher risk of delamination and eventual failure of the composite because the edges become very thin without much surrounding resin support. The layers could fray or snag on anything sharp – or even chip away under impact. The development process for the resin, the fibers, and the final composite layup focused intently on eliminating this probability and making sure the TPT Quartz and NTPT carbon layers remained firmly attached and solid.

Of course, using tennis tiger Rafael Nadal as your human test laboratory sure made that job a lot harder, and eventually, that much more successful.

White to red, my friend

Now that you generally know how the case is made, the color becomes the next point of note. Some might think that the color is something that can be changed rather easily, like changing a paint color, choosing a different metal, or using a different finishing technique. But adding color to something this technical is actually very tricky to get right.

The people at Reichhold, all the way back at the beginning of the process, would have been the ones to tackle this task because color is added to the resin. In most composites, resin is a clear material that dries into a glossy, hard surface. This means that the color (and usually pattern) you see is from the fibers that make up the composite. This is why carbon fiber is black – the fibers themselves are black.

In the first iteration of the TPT Quartz, Richard Mille wanted a clean and non-yellowing white for the quartz layers. Since quartz in this form would be mostly clear thanks to the clear resin, a white tint needed to be added to the resin to achieve the desired look.

But adding colors and tints to resins introduces a slight imbalance to the mixture that can inhibit or completely disrupt curing, especially if the tint has a chemical that conflicts with the hardening agent. This means that not fully understanding the addition of tinting liquid can cause a resin to be, at best, weaker than an untinted resin and, at worst permanently uncuring.

In my personal experiences with casting composites with tinted resins I have had both situations occur, and some others in between (like instead of solid composite it actually acts like a rubber sheet).

So Reichhold needed to do a lot of testing and fine tuning to achieve a white that was generally opaque at the same strength as the untinted resin. For the Red TPT Quartz, it had to retest everything as the new red was translucent instead of opaque (this usually means less tint added) and, very likely, a completely different chemical makeup. So a simple thing like making a red version was no small change for everyone involved.

The not unimportant rest

After the detailed description of the case and its construction, there is still the entire rest of the watch to talk about. That’s really a whole other story, but we’ll hit the highlights.

The center of the case is made from machined TPT Quartz, as are the chronograph pushers and a portion of the crown.

View through the display back of the Richard Mille RM 011 Red TPT Quartz Automatic Flyback Chronograph

The movement is a pretty “standard” (if anything at Richard Mille could really be called standard) RMAC1 skeletonized flyback chronograph movement with month, date, and a 60-minute countdown timer. The look is, as always, hardcore Richard Mille technology.

The RM 011 Red TPT Quartz Automatic Flyback Chronograph exudes a feel that is aggressive, rugged, and extremely action sport-oriented.

Almost all Richard Mille pieces are tested in extreme real-world environments, and any new case technology run through the wringer by Nadal can be assumed to be among the best Richard Mille has to offer.

The RM 011 Red TPT Quartz Automatic Flyback Chronograph is a standout timepiece among the exceptional watches in the line thanks to the advanced composite technology keeping the movement safe.

It also goes to show what a group of smart companies who are specialists in their fields can do when a forward-thinking watch brand founder comes calling for something never done before.

I wonder if they would be interested in making another prototype and shipping it my way so that I could do some independent durability testing . . . you know, just to be thorough?

A man can dream! And while I’m dreaming, I’d better do the breakdown!

- Wowza Factor * 9.44 The color is a wowza no matter what, but learning about the technology behind it adds a second wowza!

- Late Night Lust Appeal * 89.35 » 876.22 m/s2 This watch can probably take way more G forces than that, but its wearer wouldn’t survive them! Oh, well…

- M.G.R. * 63.4 Pretty awesomazing skeleton flyback chronograph with sweet features and extreme durability testing to boot.

- Added-Functionitis * Moderate/Severe First it comes with a flyback chronograph and a sixty-minute countdown timer. Then add the month and date, plus the subtle variable geometry rotor (it’s a function I declare) and you have the need for extra strength Gotta-HAVE-That cream for the technically advanced swelling.

- Ouch Outline * 10.89 Opening Plastic Blister Packaging With A Dull Knife And You Slip! Ugh! Everyone hates that packaging that is impossible to open, and it’s even worse if you maim yourself while attempting to get in. And yet, to get my hands on this Richard Mille, I would take that risk every day.

- Mermaid Moment * RED!! Unless your favorite color is anything-but-red, this watch makes you call the caterer immediately!

- Awesome Total * 655 Simple math for this one. Add the number of layers in the rough stock of the TPT Quartz/Carbon (600) to the power reserve (55 hours) and the result is still on completely technical awesome total!

For more information, please visit www.richardmille.com.

Quick Facts RM 011 Red TPT Quartz Automatic Flyback Chronograph

Case: 50 x 40 x 16.5 mm, TPT Quartz/NTPT carbon

Movement: automatic Caliber RMAC1

Functions: hours, minutes; 60-minute flyback chronograph, countdown, month, date

Limitation: 50 pieces

Price: £118,000 including tax