by Ryan Schmidt

Last week from the calm air that often precedes the SIHH storm, Greubel Forsey released a single thunderclap that rumbled across the horological community. And even more impressively, what created the loud bang was so minuscule as to be invisible to the naked eye.

So compelling was the announcement that its deep reverberation can still be heard, despite the rapid patter of new watch releases that gave way to the full-blown downpour that was SIHH 2017.

In my opinion, two things made this particular release so fascinating: first, the concept of a mechanical wristwatch movement with 180 days of autonomy is a showstopper.

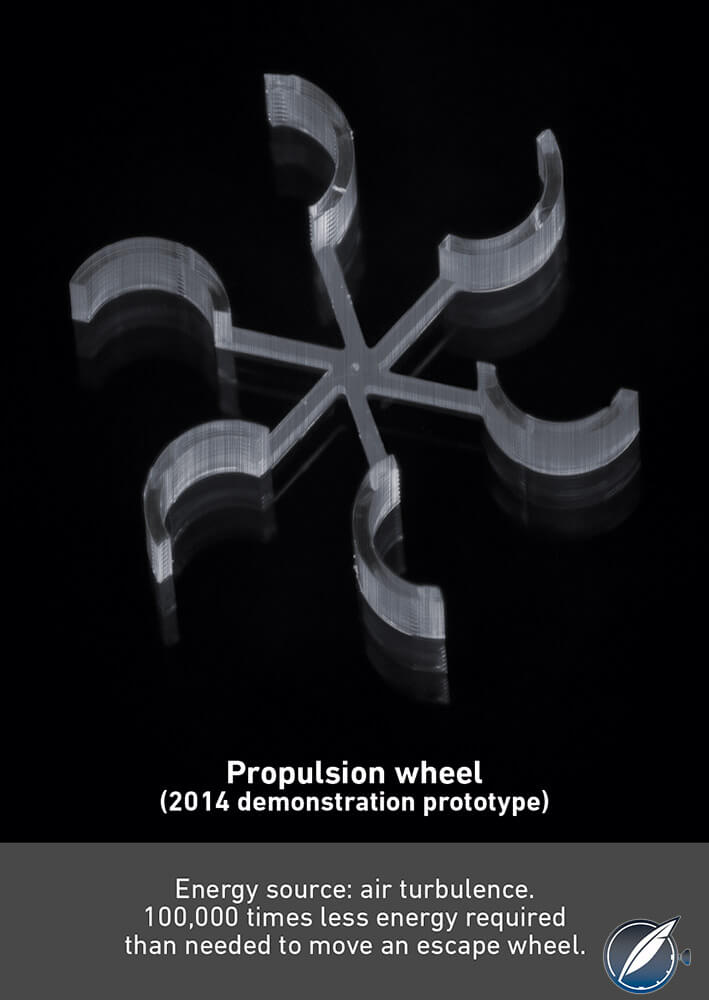

Air-driven propulsion wheel of from Greubel Forsey’s Mechanical Nano research

It’s a simple enough concept for those with a modest understanding of watchmaking to marvel at and complex enough to disrupt what the most cerebral of horologists might consider as being possible.

“Mechanical Nano” technology

Second, while Greubel Forsey provided something of an illustrated explanation for its approach, the details are shrouded within an enigmatic black box that the brand refers to as “Mechanical Nano” technology.

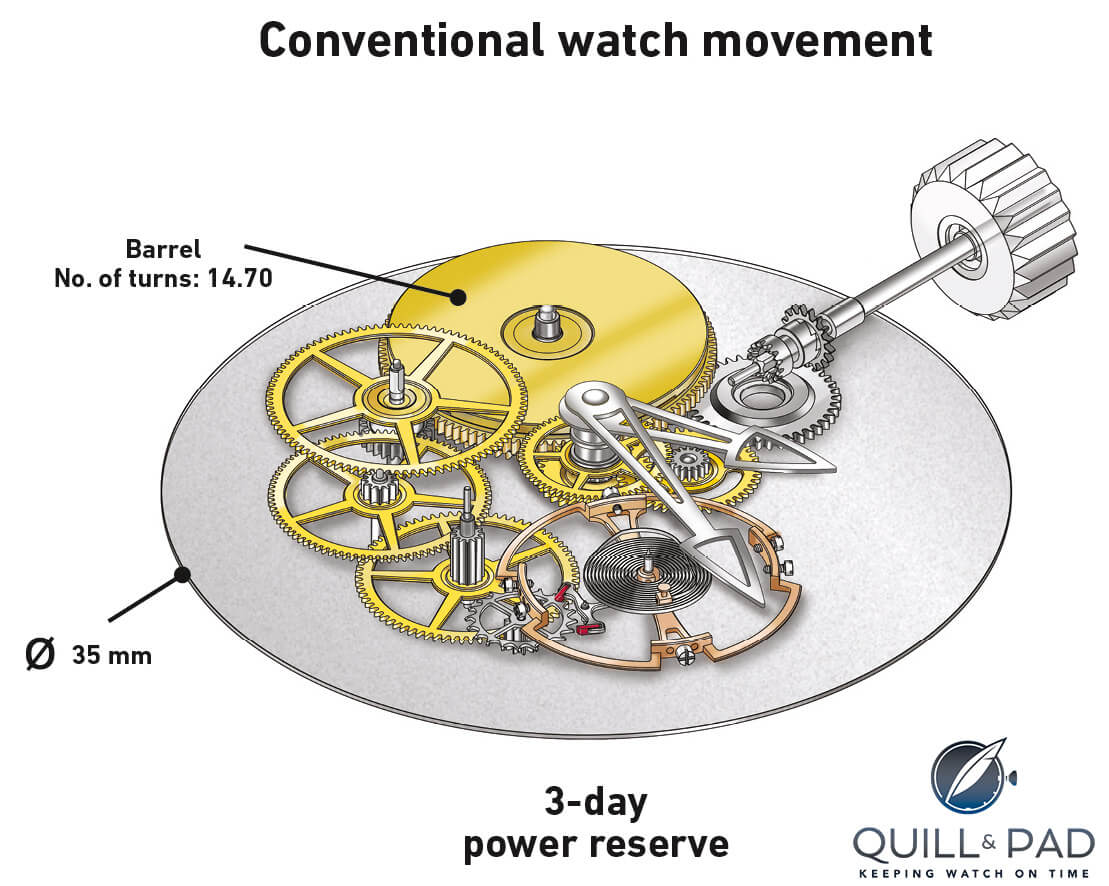

Diagram of the gear train of a conventional watch movement

In systems theory, a “black box” conceals an nonobservable process, an input being modified in an unknown fashion into an output. The black box is an abstraction, a representation of the ignorance of the viewer.

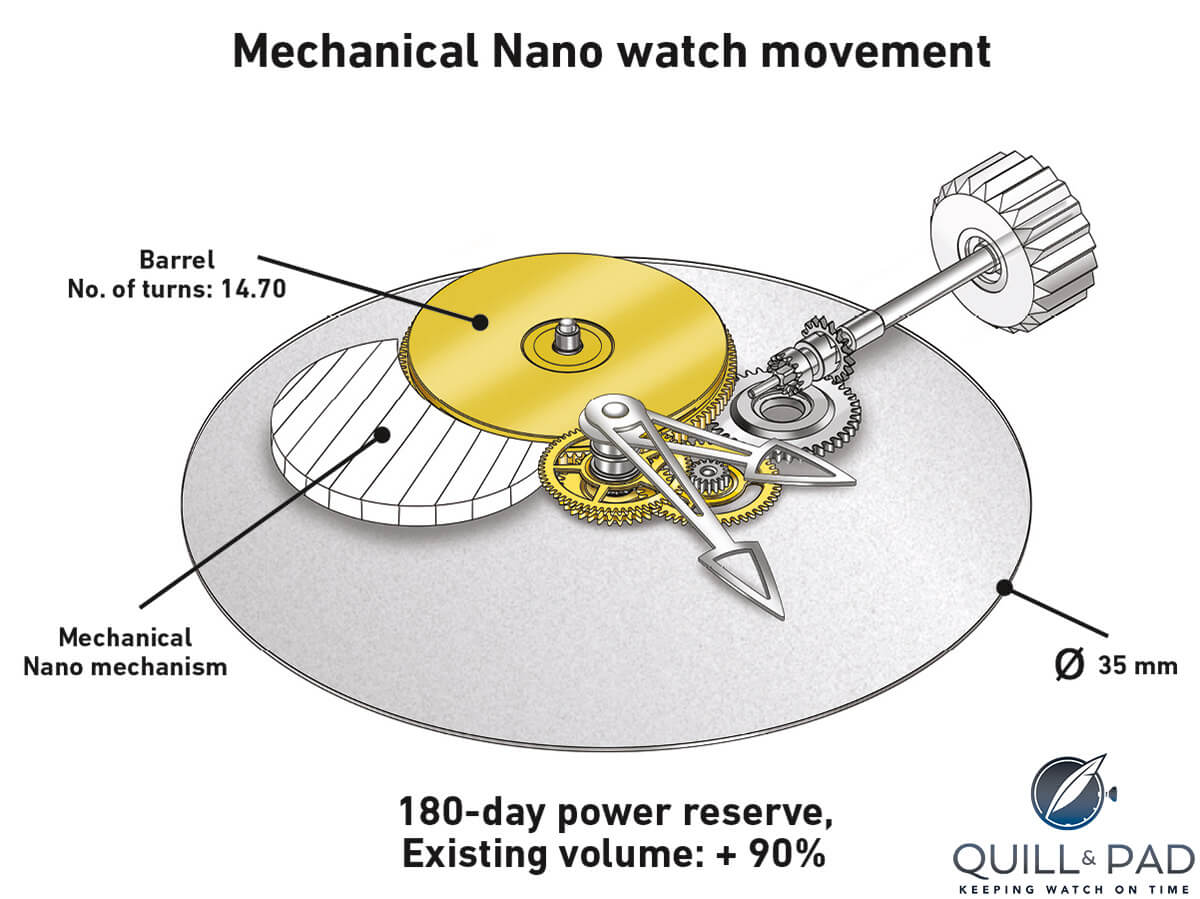

Diagram of the ‘black box’ gear train of a Greubel Forsey Mechanical Nano watch movement

To a novice, the basic diagram of a mechanical movement might be described as a black box of mechanical engineering. You wind the crown and timekeeping occurs. The mass of wheels and springs overwhelms the novice, but it does not give rise to frustration or panic; instead the black box inspires awe: I wind my watch and timekeeping occurs because of “science.”

We can bundle all of our uncertainty into that black box of engineering, set it aside, and simply be proud that mankind has created something as marvelous as a watch.

But of those who appreciate the work of Greubel Forsey, perhaps even those who have simply only heard of the brand, there are many who no longer view a mechanical movement with such wide-eyed awe. These people have the skill to orient themselves along a visual trail taking them over plates and under bridges, from the mainspring to the balance wheel, jeweled bearing by jeweled bearing.

In doing so, everything drops into place, the black box disappears and a gentle familiarity embraces the knowledgeable viewer.

This familiarity enables us to observe the quiet details and the abnormalities. A frosted bridge here, a star wheel there . . . but a Mechanical Nano what?!

Indeed, just before SIHH 2017 opened, Greubel Forsey placed an extremely small, but equally compelling, black box in front of us.

I, for one, am very curious to learn what is inside that box right this minute. And while I expect the details to arrive piecemeal over the coming weeks and months, I am afraid I could wait no longer so I decided to close my eyes and transport myself through the walls of the box and into its nano-sized contents.

Horological speculation

The following is a documented exercise in horological speculation. It is not a statement of fact, but rather a consideration of the theoretical.

As a consequence, it might be far from the mark when Greubel Forsey finally lifts the lid of its black box, but I hope that it provides your curiosity with something to sink its teeth into before that day comes.

How is the timekeeping gear train driven?

With a conventional watch movement, the teeth of the mainspring barrel drives the pinion of the center/second wheel, which carries the minute hand.

Take a look at the diagram of the conventional Greubel Forsey movement (which appears to represent Signature 1). This three-day movement delivers 72 rotations of the minute hand in 14.7 barrel turns. So every turn of the barrel delivers slightly fewer than five rotations of the minute hand: 4 hours, 54 minutes, and 53 seconds to be precise.

Now take a look at the diagram of the Mechanical Nano movement.

Greubel Forsey claims that the barrel will deliver the same number of turns, but unlike the 72 rotations of the conventional minute hand, the minute hand of the Mechanical Nano movement will rotate (brace yourself) 4,320 times!

What does this mean? It means that the barrel is not directly driving the pinion of the center/second wheel. The gear ratio is impossible. Signature 1 needs around 75 teeth to drive a 15-leaved pinion on the center wheel.

If the barrel of the Mechanical Nano movement were to directly drive a similar pinion, it would require more than 4,400 teeth! Bearing in mind that ideal teeth/pitch ratios are between 4:1 and 10:1, we might assume that the nano mechanisms are not driven by any conventional means Regardless of the many breakthroughs in nanofabrication, the physics of standard gearing is very unlikely allow power to transmit across a ratio of 294:1.

Therefore I expect that, despite the appearance of the Mechanical Nano movement diagram, the timekeeping function will not be driven directly by the barrel, rather it will be driven by an intermediary gear train that dramatically increases rotation rates before engaging the wheel of the minute hand.

The gear train is likely to be included within the black box, because when talking about there being three times less components over a conventional movement, it appears that Greubel Forsey counts all componentry within the box as a single unit.

This gearing could theoretically be achieved using a train of four to five wheels at traditional ratios, however you might imagine the effect that this would have on power if you were to use traditional materials and escapement speeds.

So power and regulation is the weak link.

How is the movement regulated and powered?

Following on from above, let’s assume that somewhere within the Mechanical Nano mechanism, or somewhere not detailed in the enigmatic diagram provided by Greubel Forsey, there is a four-wheel transmission between the barrel and the wheel of the minute hand.

What would happen if we used a conventional escapement and balance to regulate and distribute power? You could no longer use a five-wheel gear train because the barrel wheel would be moving 60 times slower than a conventional barrel.

If you did, you would need to employ a balance wheel vibrating at about 0.05 Hz as opposed to 2.5 Hz with Signature 1.

This is not an impossible concept in a clock – just take a look at the balance of the Jaeger-LeCoultre Atmos, which vibrates just once per minute – but imagine thrashing about with that regulatory organ on your wrist; it would be catastrophic to timekeeping.

When dealing with a mechanical movement, adequate regulation means speed. The most common regulator with the minimum acceptable speed is 2.5 Hz (18,000 vph). With the Mechanical Nano movement, even a modest 2.5 Hz balance wheel would require some radical gearing to be driven by such a sedentary mainspring barrel.

Using conventional ratios you would need a gear train with something in the region of seven to nine wheels. However, a conventional gear train tends to have four wheels, and adding any additional load (such as additional train wheels or tourbillon carriages, for example) is a power eater.

You can have perfectly calculated gearing, but without the necessary power the escape wheel and lever will fail to provide adequate impulse power to the balance. Sure, you can ramp up your power to compensate for this, but there is only so much that the upstream components can take.

This is why the secret to extended power in a mechanical watch is a mixture of extra teeth and extra mainspring power, but there is a ceiling to this technique, and 180 days of autonomy is an entire starry sky above that ceiling.

This is where the black box comes in. We know that the input is the barrel wheel, which turns at a rate of one rotation approximately every 12 days. The output is regulated timekeeping delivering Greubel Forsey levels of accuracy.

Somewhere in that opaque space is the solution, and it will contain no conventional gear trains or regulators.

So what’s in the black box?

Eventually Greubel Forsey will lift the lid on its microscopic black box, and Quill & Pad will be there to help translate exactly what is going on in there. Until then, here is my theory.

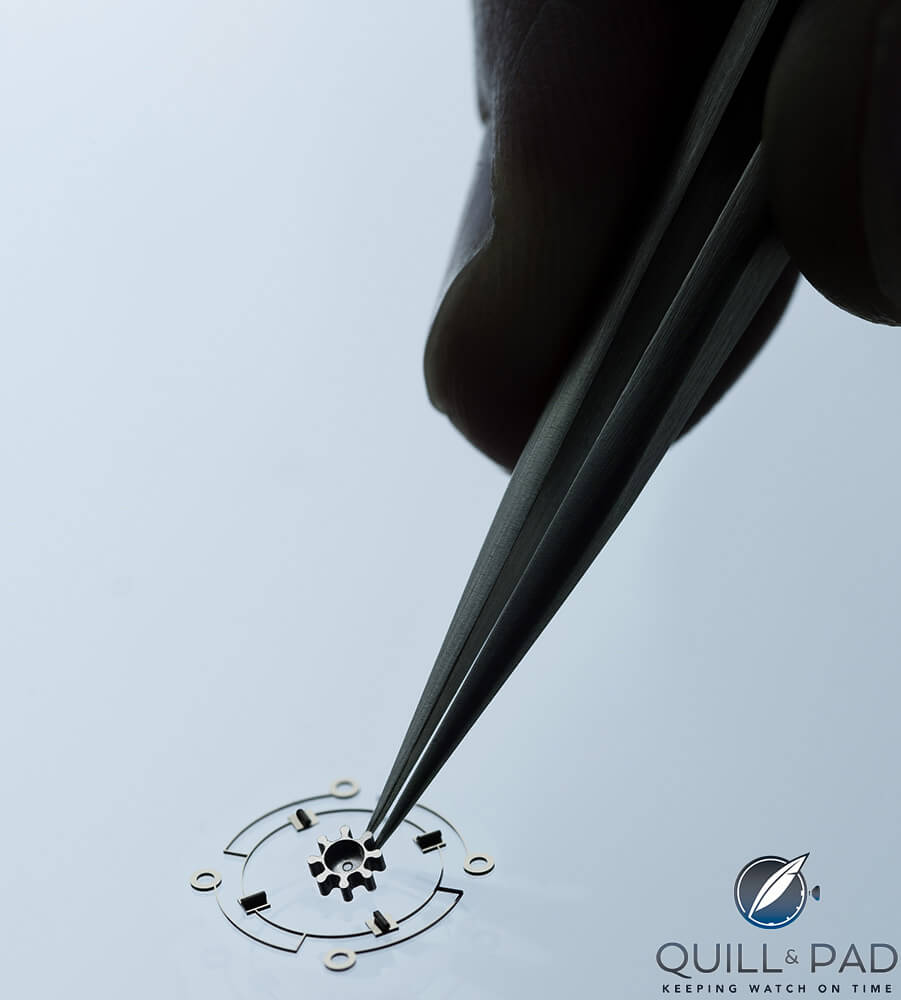

The Mechanical Nano mechanism is designed to be extremely small and extremely light. The reduced size enables Greubel Forsey to place within it a series of aggressive gear ratios that transmit miniscule incremental turns of the mainspring barrel into a wheel speed allowing adequate regulation. The reduced greatly mass of the gearing serves to reduce the power loss across the gear train.

I expect that the barrel teeth will drive an intermediary pinion within the box that has a relatively large wheel on its arbor. The pinion will be conventional, but the additional wheel will be made of silicon and will carry an exceptional number of nano-sized teeth.

These teeth will drive a fully nanofabricated pinion/wheel with a large number of leaves/teeth. This process will enable a rapid increase of speed.

For example, let’s say that the intermediary pinion has the conventional 15 or so leaves. Each turn of the mainspring barrel (with about 75 teeth) will turn it five times – a conventional 5:1 ratio.

But unlike a conventional wheel, the nanofabricated wheel that shares an arbor with the intermediary pinion will have, let’s say, 1,000 teeth. These teeth mesh with the nano leaves of the next pinion in the train.

Let’s say that the pinion has 100 nano leaves. Where does this get us? It gets us two wheels into the train, and we are now rotating once every six hours or so, versus the >12 day rotation of the mainspring.

The good news is that Greubel Forsey has lots of space, and lots of energy, so the Mechanical Nano mechanism can run several further 10:1 ratios within the box.

Of course, the ratios would be tweaked to suit the diameters and positions of the wheels as well as the oscillating frequency of the regulator, but using the 10:1 ratio to take us all the way home we are left with a sixth wheel turning once every two seconds.

Therefore, thanks to the jump from the micro-sized teeth on the barrel wheel to the nano-sized teeth on the intermediary wheel, and with the help of two extra wheels versus a conventional gear train, the Mechanical Nano mechanism has the potential for an escape wheel rotating four times faster than a conventional escape wheel.

But Greubel Forsey cannot simply place a conventional Swiss lever escapement on the end of this train to power a high-speed oscillating balance. The power impulse requirements of the lever are likely to far exceed what the escape wheel could provide; and if you ramped up the strength of the mainspring it would certainly be a problem for the silicon teeth and the pivots throughout the gear train.

It is therefore likely that the Mechanical Nano mechanism will employ a radical, high-speed, low-power escapement/oscillator.

Perhaps the hint is the propulsion wheel in the image provided by Greubel Forsey?

What if instead of an oscillating balance, the gear train continued onward and onward until the wheels were moving so fast and with such minimal mass that the final wheel simply spins as a constant flow escapement, similar to a governor on a repeater escapement?

Is it possible that these ratios, scales, materials, and forces combine to minimize the effect that torque and other fluctuations would have? Perhaps, but, it just seems too unlikely to me that the rate would be remain acceptably stable.

I suspect that this propulsion wheel is something of a red herring. A experiment to study end shake and speed, but ultimately I cannot imagine an unlocked gear train relying on air to break or power it without sacrificing significant accuracy.

I therefore do not expect that we will find this propulsion wheel within the black box. Instead, what I am expecting – hoping for, in fact – is something along the lines of the Résonique.

The Résonique oscillator is a revolutionary product of the research and development lab at De Bethune. It was released as an open-source technology to the horological community back in 2011 and it is the perfect regulator for a low-power, high-frequency, movement.

The technology involves a magnetic escapement rotor surrounded by an “acoustic resonator” with tiny magnetic bars. Each escape tooth operates as a magnetic pole and their near contact with the magnetic bars causes the resonator to contract for an instant before returning to original form.

De Bethune Résonique high-frequency escapement

In the process of each contraction, the magnetic escape wheel is momentarily “unlocked” from its magnetic field. De Bethune produced a working prototype delivering a shockingly fast frequency of 926 Hz.

Therefore I conclude that Greubel Forsey will not stop at six or seven wheels in its gear train.

Instead it will take full advantage of the nano technology by creating a 9+ wheel gear train leading to a magnetic escape wheel rotating approximately 100 times per second and unlocked by the circa 926 Hz acoustic resonator.

Although we are well into theoretical wilderness, this might just be it.

Beam me up, Scotty!

In fact, if the above can be successfully delivered, it is not too hard to envisage adding a few more wheels, and now you are unlocking the further potential of the Résonique, which De Bethune predicts to be capable of up to 20 KHz!

So there it is: a reverse engineered black box. Of course, we might learn that that Greubel Forsey has gone about this in an entirely different way.

Air-driven propulsion wheel from Greubel Forsey’s Mechanical Nano research

One thing is for sure: whatever lies in that box, it’s sure to amaze and it will be an equal pleasure to stand vindicated or corrected!

Watch this space for more updates.

Trackbacks & Pingbacks

-

[…] A cool side effect of the development is that this microscopic loupe was used again at SIHH 2017 to benefit viewing of the secretive new nanotech we were fortunate enough to get a sneak preview of (see Black Box Theory: The Greubel Forsey Mechanical Nano Movement Explained With A Wild Guess). […]

-

[…] IS: The highlight for me was also the Greubel Forsey Grande Sonnerie, though I was also both impressed and intrigued by Greubel Forsey’s Mechanical Nano (see Black Box Theory: The Greubel Forsey Mechanical Nano Movement Explained With A Wild Guess And Live V…). […]

-

[…] have a look at this short video And an explanation here…well sorta.Black Box Theory: The Greubel Forsey Mechanical Nano Movement Explained With A Wild Guess And Live V… Regards, Time is what keeps things from happening all at once. There is no time at the […]

Leave a Reply

Want to join the discussion?Feel free to contribute!

Amazing development from GF.

I really hope the magnifying optic is not integrated on the final watch. Given the Mechanical Nano movement and reduced space, I would hope for a much smaller and less bulky GF timepiece.

Thanks, Cory, it’s very exciting. I think they will reserve the magnifying lens for their art pieces, and while I wouldn’t put it past them to somehow chamfer a nano-spoke, I expect them to black polish the box itself to within a nano-inch of its life.

Hey Ryan,

This is really exciting stuff. The mechanical nano could just be the concept watch I have been waiting for from GF. May be a new case design? Will the black box remain opaque? I would love to see the propulsion wheel visible in the movement but I’m guessing it will be nano small. Lots to discover and look forward to… any idea when a final piece will be released?

Hi, Cory, it’s going to be fun to find out. According to GF: “Greubel Forsey will regularly share updates on these research developments in 2017 and 2018 with, notably, the fruits of research from the first two prototypes. We are now working on the first mechanical Nano timepiece, which will be unveiled in the near future.”

Thanks Ryan,

It is going to be fun finding out more for sure. GF continue to amaze like no other… I wonder if we can expect to see a nano tourbillon within the timepiece… that would be impressive! Even if it is not completely visible to the eye. Let’s wait and see.