Coloring Watches: PVD (Physical Vapour Deposition) and ALD (Atomic Layer Deposition)

There are two key technologies used for the coloration of luxury watches and movements, PVD and ALD.

Invented in 1838 by English scientist Michael Faraday, PVD (Physical Vapour Deposition) is the application of thin layers of metal coating onto metal surfaces such as watch cases and movement parts.

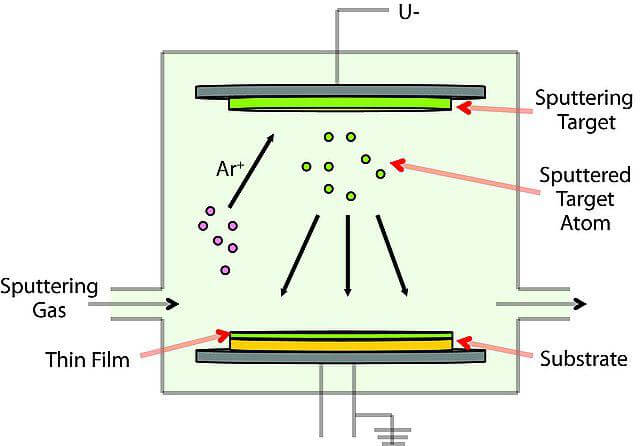

This figure gives a simple illustration of the process of PVD where the desired deposited gas molecules enter the chamber after being condensed, and then are condensed once again onto a thin film, such as the anisotropic glass (image courtesy sigmaaldrich/Wikipedia)

The metal to be applied (e.g. titanium, gold, aluminum) is changed into a gas or vapor form and its atoms are then precipitated onto the metal to be coated.

Urwerk UR-220 “Falcon Project” Edition All Black PVD-DLC

The process takes place in a vacuum chamber and at low temperatures (between 50 and 600 degrees Celsius). PVD coatings are remarkably durable and ensure long-them protection from corrosion and scratches, as well as a lustrous appearance.

Omega Speedmaster Moonwatch Black Venom PVD-DLC

The most common coating used in watchmaking is diamond-like carbon (DLC) which delivers high degree hardness and protection against wear.

PVD colors used in luxury watches include gold, brass, black, rose gold, chrome, blue and silver.

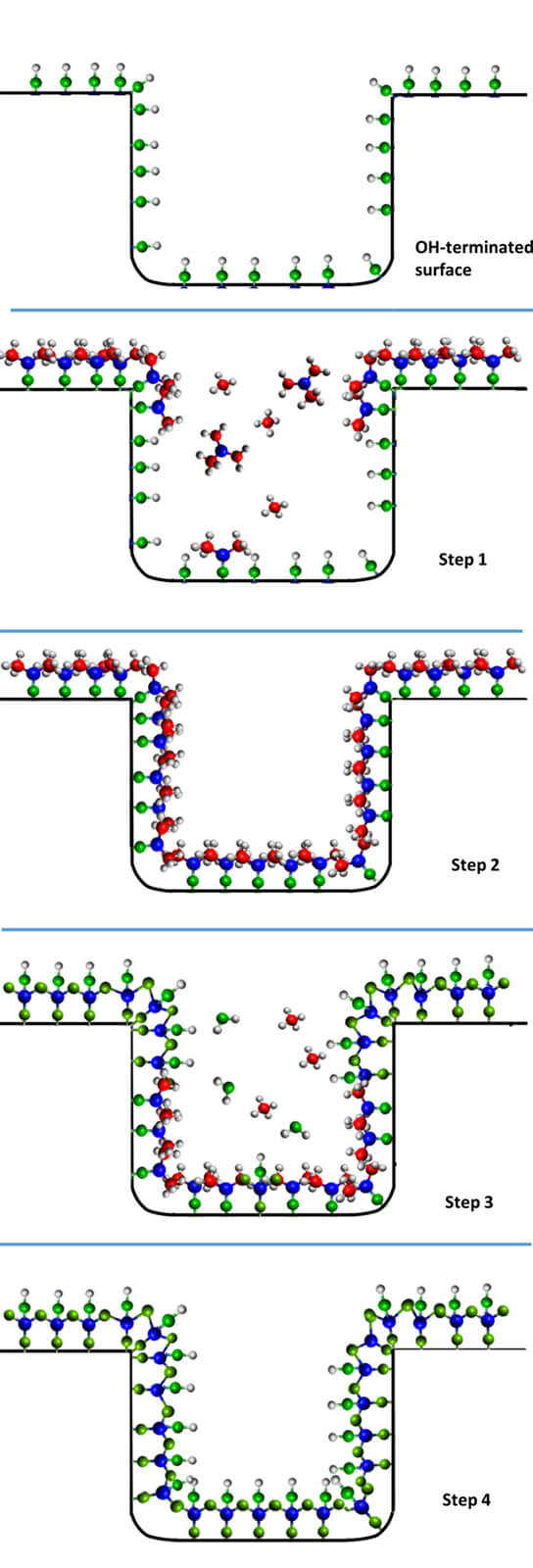

Schematic illustration of one reaction cycle of the ALD process, using the trimethylaluminium (TMA) -water process to make thin aluminium oxide films as (simplified) example. There, the starting surface contains hydroxyls (OH groups) as reactive sites; Step 1 is the reaction of TMA; Step 2 is a purge or evacuation step, Step 3 is the reaction of water, and Step 4 is a purge or evacuation step (image courtesy Véronique Cremers, Riikka Puurunen, Jolien Dendooven/Wikipedia)

ALD (Atomic Layer Deposition) was introduced in watchmaking around 2014, by the company Positive Coating. It delivers better uniformity and a better control of the deposition thickness on complex geometries, than PVD coating.

In 2021, Positive Coating introduced an innovative new ALD coating which allowed the production of rainbow gradients on watch components, using several colors or different tones of the same color.

Zenith Defy 21 Felipe Pantone

A first application of the new technique was made on the Zenith Defy 21 Felipe Pantone launched in 2021.

You might also enjoy:

5 Reasons Why You Should Consider Owning a Colorful Watch

M.A.D.Editions ✕ Jean Charles de Castelbajac ‘Time to Love’

Leave a Reply

Want to join the discussion?Feel free to contribute!