Without glass we would live in a world of blind darkness.

Without glass we would have lost ships at sea; we would never have seen the wonders of space or the marvels of the microscopic.

Without glass scientific instruments would be rudimentary at best, and no one would have ever had the opportunity to sip on a bottle of 1945 Château Mouton Rothschild (the Quill & Pad house wine, of course) with dinner.

To put it bluntly, a world without glass would be a pretty boring place. Houses would be dark, the internet would be slow, and the stars would only be bright pin pricks in the sky.

Glass has a long history and an enormous range of uses in the modern world. From everything to windows, lenses, fiber optic cables, cookware, containers, and structural fiberglass, glass has become a wonder material in its simplicity and abilities. It helps to make almost everything we do possible in one way or another.

It facilitates communication around the world, visions of galaxies far, far away, and eating foods from distant lands, or at least somewhat distant farms.

Glass origins

The origins of glass are unclear (see what I did there?), but we do know that the earliest true glass objects found were beads fashioned in the third millennium BCE, likely as an accident of a metalworking process or during the creation of a ceramic-like material called faience.

As time progressed, glass-working slowly grew before being more or less halted by the fall of the Bronze Age. Evidence suggests it was independently developed in south Asia around 1730 BCE, though western culture didn’t rediscover the techniques for making glass until late in the Roman Empire.

Glass has been widely used because of its unique properties, which has also made for many amazing creations even in the early days of glass-making.

Being an amorphous solid (uniform and non-crystalline), it has the ability to be uniformly clear and transparent, which is very desirable for many uses. It also displays a glass transition (appropriately named, don’t you think) where the material transitions from a hard and brittle solid into a molten or putty-like state that allows for manipulation, blowing, molding, and shaping for use in specific circumstances.

These abilities allow for the material to be shaped into holding vessels, optical lenses, and other structures that benefit from being hard, clear, sterile, and easily shaped. A structure benefiting from these properties − well, perhaps being sterile isn’t crucial, but it is nice − is the hourglass.

The hourglass is a structure that is most successfully made from glass as it is required to be perfectly transparent, have a low amount of friction (oh yeah, glass has relatively low friction if the surface is not tampered with during cooling), be easily shaped into a dual-ended funnel, and be hard and durable for consistent operation.

A vital navigation tool

The hourglass is actually an object that has greatly aided the exploration of the world ever since the thirteenth century. It was used extensively on ships to help chart courses and determine longitude.

Since the timekeeping device that went before it, the clepsydra or water clock, was strongly influenced by the motion of ships at sea, the hourglass provided a useful alternative that was independent of ships rocking.

The sand, powdered marble, or powdered eggshell filler was not subject to rocking forces as much as liquids were, plus they were less affected by temperature changes and problems associated with condensation caused by variations in pressure and humidity.

Because of this fact, before the marine chronometer was invented the humble hourglass was a vital navigation tool well into the age of mechanical timekeeping. It even helped the Magellan voyage circumnavigate the world thanks to an impressive 18 hourglasses per ship. These were kept in different sizes to more accurately keep track of time, usually in increments of 15 minutes, and were referenced to the noontime sun at its zenith.

As it was the predecessor to everything they now know, the world of horology either is, or at least should be, infatuated with the historic hourglass. Even though it isn’t mechanical, the size of the granules, diameter of the neck opening, and shape of the funnel and bulbs can be very carefully defined to create a relatively stable, repeatable and accurate timekeeping device.

It can also be incredibly beautiful and breathtaking. Exhibit A: the Ikepod Hourglass by Marc Newson.

Blow it out

My first experience with this object came from an incredibly artistic video documenting its creation in the shops of Glaskeller in Basel, Switzerland. You absolutely need to watch it, but not yet. First, let’s talk about the creation, the techniques involved, and why it is as breathtaking as it is.

To make the hourglass, the glassblowers begin with a long tube of perfectly clear borosilicate glass. You may recognize borosilicate glass as the material used in Pyrex glass products, since that was the first iteration of such glass.

It has more robust properties compared to standard glass (soda-lime glass) in that it is much less sensitive to the stress of thermal expansion, making it more thermally stable and dramatically reducing the tendency to crack or shatter from thermal shock.

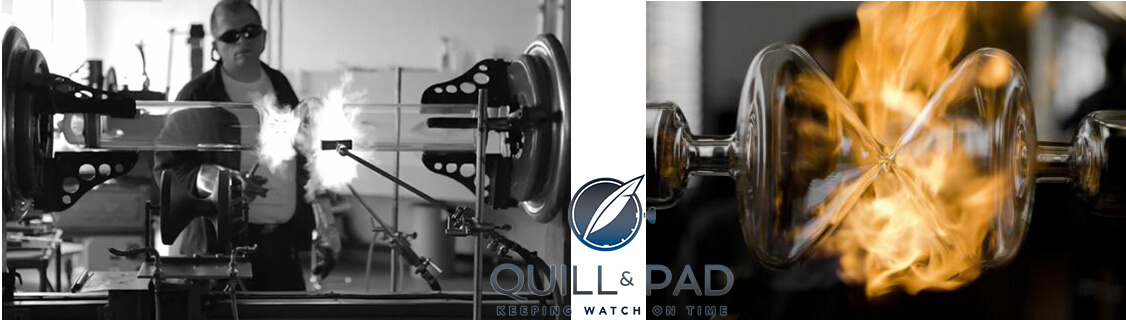

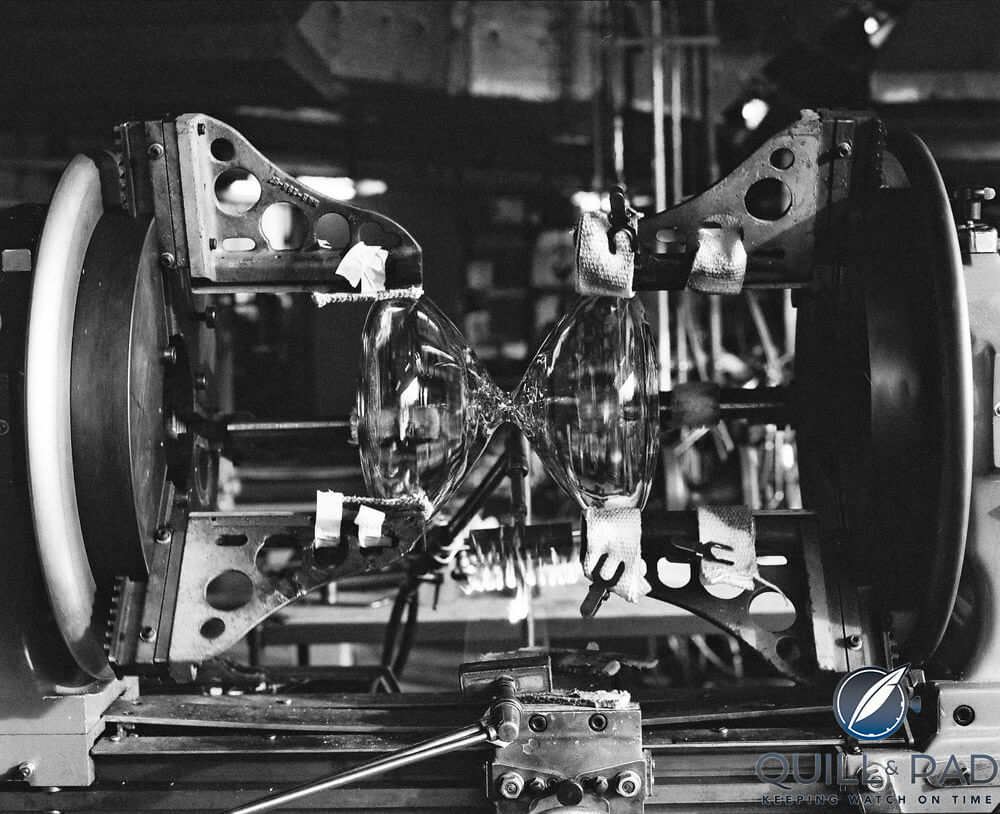

The glassblowers take the tube and mount it in a large glass-working lathe with jaws specifically designed to hold glass tubes for blowing. The ends of the tubes are sealed and a hose for blowing is added so as it rotates the glassblower can introduce positive pressure into the chamber.

Multiple gas torch flames are placed around the tube as it starts spinning, heating the piece carefully to the lowest end of the glass transition temperature. This way the blower can gently nudge the glass in different directions, deftly controlling the movement and constantly checking dimensions.

Once the glass transition temperature is reached, the neck of the hourglass is formed by slowly pinching the glass with a set of calipers. A graphite paddle is also used to push the material toward the center point while maintaining a smooth slope without ridges, bulges, or lopsided shapes. All of this is achieved while the tube is constantly spinning with the flames adjusted to the required positions for maintaining heat and proper pliability of the glass.

After the neck is close to the final shape and size, the bulbs of the hourglass are formed by gently blowing into either end while smoothing into the desired shape using the paddles. Underneath the spinning tube, a graphite mold rests on a carriage that can be moved into position, raised and used as a smooth guide for final sizing and shaping.

Then the piece must be detached from the unshaped portion and closed off. This is actually done in multiple stages to ensure that the hourglass shape isn’t compromised. One end is then completely sealed while the other is closed off except for a small hole left for filling with the granular material.

Did someone say nanoballs?

Both the shaping of the glass tube and the final hourglass go through numerous tempering steps in a large oven to ensure that any stresses created in the material are removed and that the structure is stable. Once the glass is considered stable and in its finished shape, it is then filled with the granular material of choice.

And what exactly is that material? Well, nanoballs!

Okay, that is really just a fancy name for really, really tiny stainless steel balls that are coated in a variety of materials. While they are not technically nano-sized (which is one-billionth of a meter, or approximately the width of DNA), they are pretty darn small, with the 60-minute timer version filled with approximately eight million of the little things. For the smaller 10-minute timer version there are only a measly 1.3 million nanoballs.

The nanoballs are available in four finishes, one of which is uncoated stainless steel. The others are a black DLC nickel plating, copper for the Westime (Los Angeles) limited edition, and yellow gold for The Hour Glass (Singapore) limited edition. Ikepod has also released a unique piece in red glass for Only Watch 2011, and a line of 10-minute timers in blue glass as well.

And every one of them is gorgeous. But what is more stunning is that video I was telling you about earlier. I think it’s time to sit back and enjoy the majesty of creation, the hourglass creation that is.

Oh, and if you have already seen it, watch it again. I watch it every few months or so just because it is so darn good.

While you bask in the magnificent work that went into this piece, I want to reiterate just how visceral the hourglass is. The object itself has been around for hundreds of years, and the simple outline of one is almost universally understood.

The hourglass has graced computer screens for years (at least it used to) and still makes little children and myself stare with fascination. Time told by gravity, harnessed by ingenuity.

I don’t know that there is anything more poetic than sand through the hourglass…”so are the days of our lives.” I couldn’t resist that little soap-opera-inspired quote, but it does hold true.

There aren’t many things as relaxing and enjoyable as watching sand (or nanoballs) cascading through an hourglass, suggesting the passage of time but not holding it hostage. It is an emotional experience, and with the Ikepod Hourglass, it is also a beautiful one.

For more information please visit www.Ikepod.com.

Quick facts:

60-Minute Timer

Size: 300 x 250 mm

Weight: 9.6 kg

Nanoball volume: 8 million nanoballs

Retail price: $31,500 (Westime limited edition)

10-Minute Timer

Size: 150 x 125 mm

Weight: 1.5 kg

Nanoball volume: 1.3 million nanoballs

Retail price: $13,000 (Westime limited edition)

Trackbacks & Pingbacks

-

[…] three clocks with Jaeger-LeCoultre as well as other projects within the world of horology (see Glass, Nostalgia, And The Ikepod Hourglass), it’s probably fair to say that at this point in his long career he could choose among pretty […]

Leave a Reply

Want to join the discussion?Feel free to contribute!

Thanks for an absolutely fascinating article, Joshua! It provides a whole new perspective on hour glasses. You’re right, the video clip is really interesting. Thanks again!

Thank YOU for taking a look! We try to provide different perspectives…