by GaryG

One of the great things about making friends in the collector and watchmaking communities is that sooner or later, one starts receiving invitations to visit the places where the creative thinking and beautiful handwork in horology actually happens: the manufactures of the big brands and the ateliers of the independents.

I’ve now had the opportunity to take part in many such visits and I can tell you with some confidence that there is nothing quite like visiting with Vianney Halter at his workshop in the small Swiss town of Sainte-Croix.

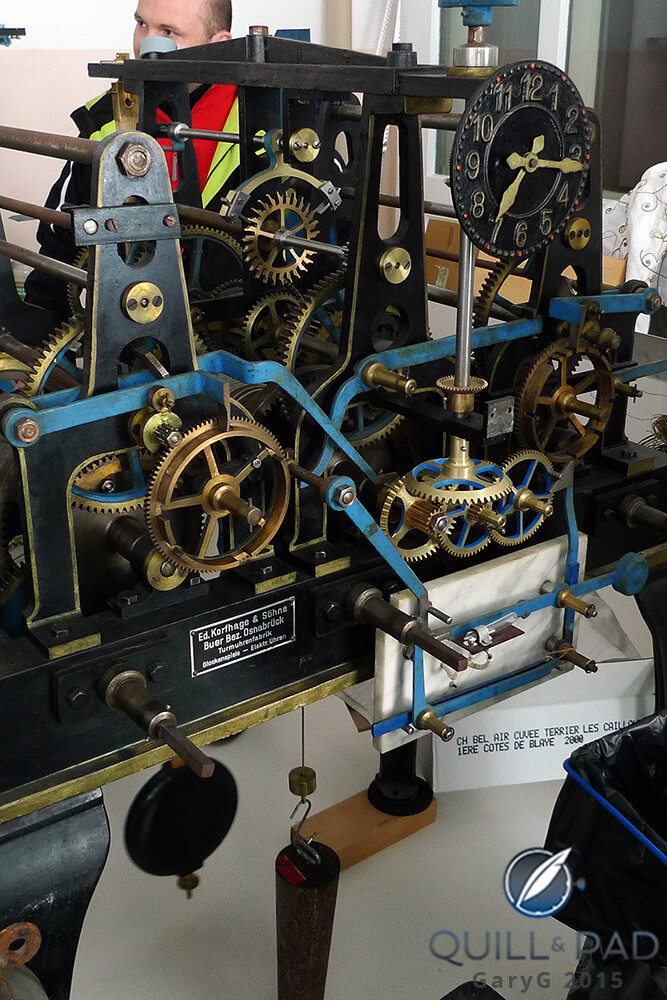

Immediately upon entering the sizable factory building on the ground floor, one is ushered into a wonderland of mechanical oddities, including tower clock movements, huge watch movement models, wall-sized exploded drawings of Vianney’s watches, and curiosities such as a small-scale, operational model of a fire engine.

Just as all of this is beginning to sink in, it’s up the stairs to the level where both component fabrication and watch assembly take place. Fortunately, these activities take place in separate areas as steps like heat treatment using powdered charcoal and a blowtorch throw off considerable soot.

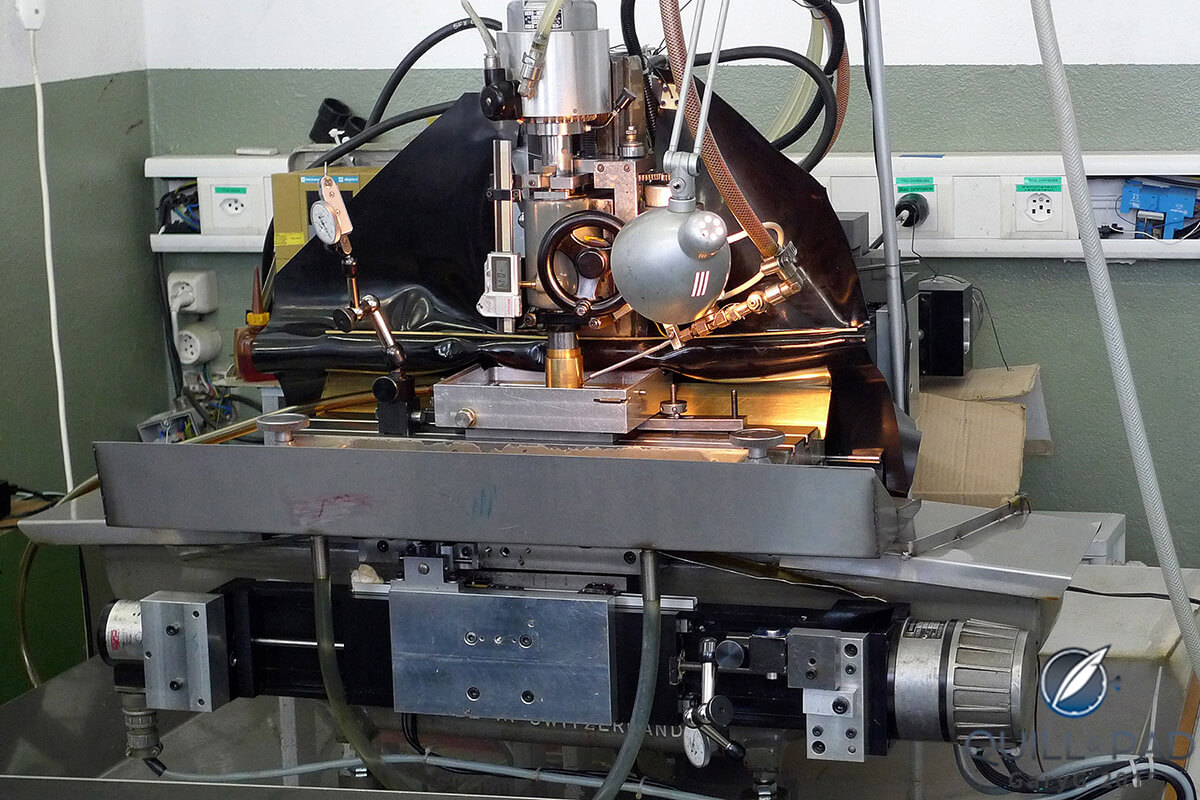

People who have visited Vianney sometimes describe the workshop as a “mad scientist’s lab,” and you can see why when you are shown manufacturing tools like the homemade, automated milling machine (below). Made from a combination of manually fed milling machine, in-house-fabricated, motor-driven positioning rig, and what appears to be a late 1960s Univac computer cabinet filled with clacking relays, it is a tribute to Halter’s ingenuity and independent streak.

And it must work as it is the source of a very large number of the bridges and springs used in the Vianney Halter watches.

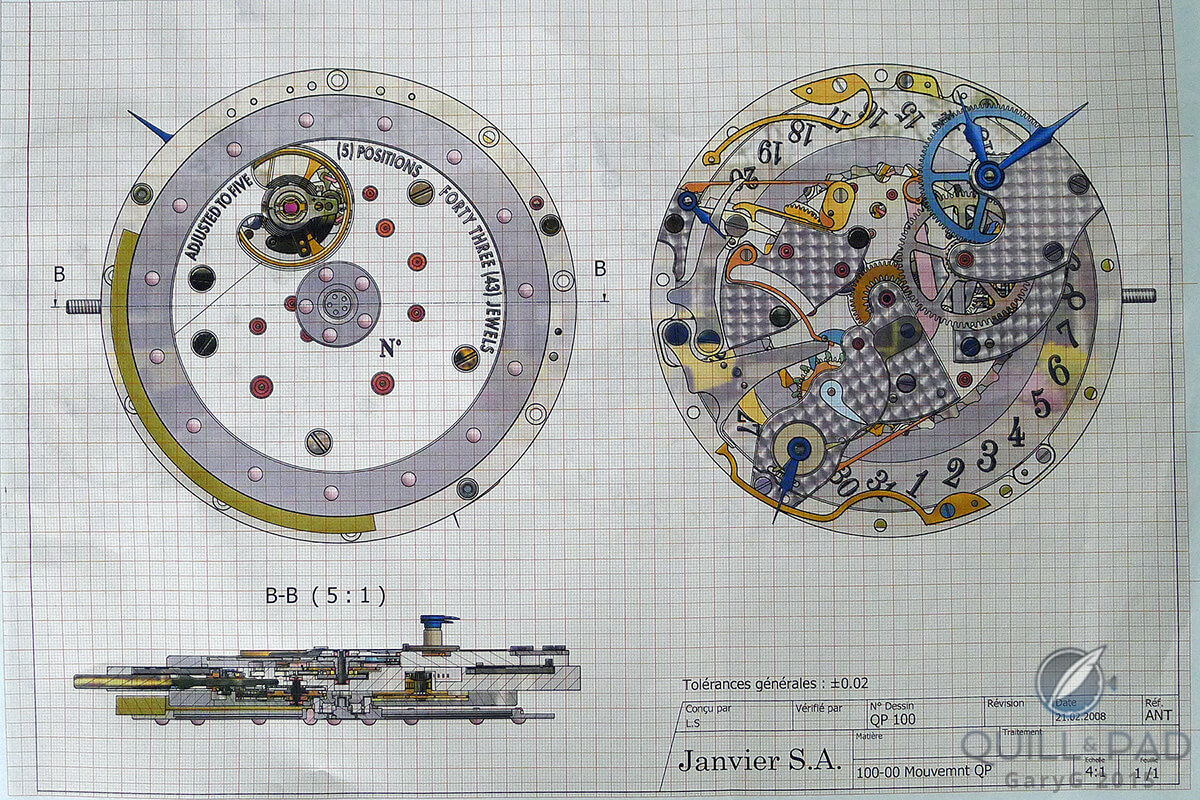

Upstairs (as on the ground floor) detailed drawings of elements of Vianney’s watches are very much in evidence. On my second visit to the factory, this turned out to be very helpful; I was having a bit of trouble with the date change on my Antiqua, and the watchmakers were able to show me exactly which spring in the perpetual calendar movement would need to be re-made in order to provide the proper motive force.

Since Halter’s watches are produced in such small numbers and many of them (like the Antiqua with its instantaneously jumping perpetual calendar complication) are quite complex, it stands to reason that over the life of the production runs, he identifies and implements ongoing improvements.

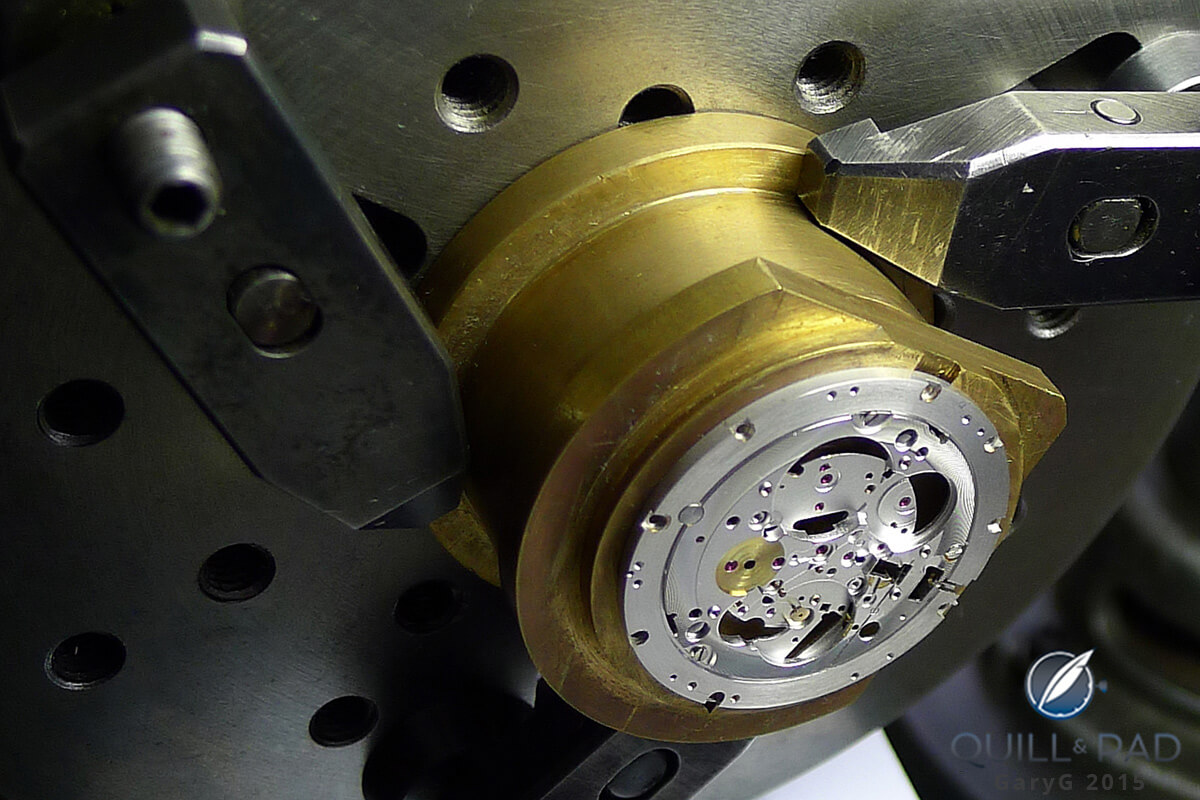

When earlier watches come back for maintenance, Halter and his team incorporate those updates. Below, we see an Antiqua base plate being re-machined to enable relocation of other movement parts.

The assembly area is a watch lover’s wonderland with trays of parts for all of Vianney’s different timepieces ready to be used as needed for new watches or repairs.

One of the great treats for me on my most recent visit to Halter’s factory was to see my Deep Space Tourbillon under construction. It’s a wonderful experience to see something like that in the making and also to see (and discuss) elements of the watch – such as the Deep Space Tourbillon’s ratcheted tourbillon carriage, which is essential to its function but is not visible in the finished watch.

No visit with Halter is complete without a visit to the attic! More big clocks, sextants, and a collection of instruments from electrical power plants number among the hundreds of items that clutter the unheated top floor.

And if your tower clock needs a replacement pendulum, you now know where to go.

Before departing, it’s time to see some finished watches. Some, like the Goldpfeil shown here, are in for repair or routine servicing.

And if you’re lucky, you get to see a real rarity like the Classic Janvier model with its two-disc shadow moon and marchante equation of time indications.

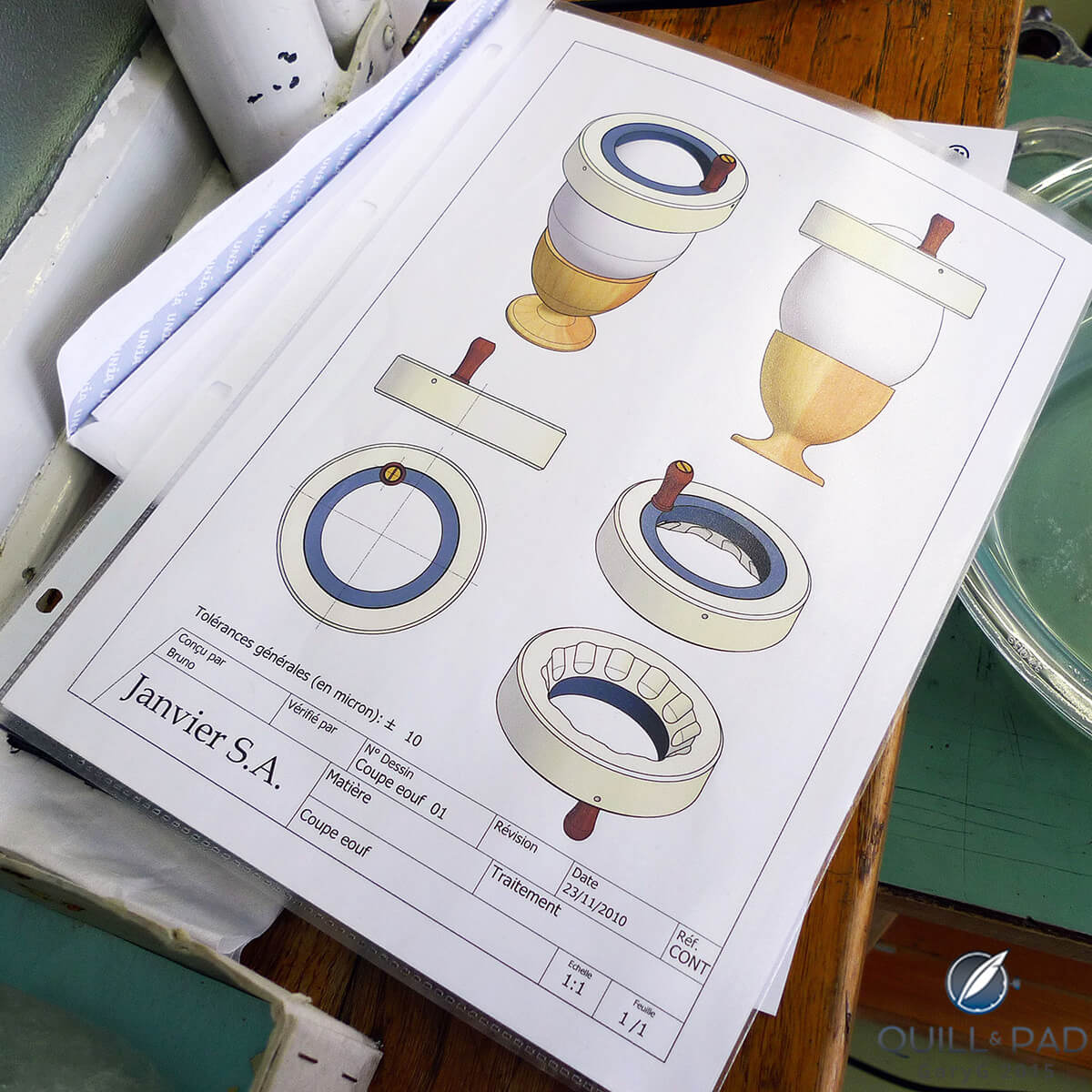

Speaking of luck: on one of our visits, our group caught a glance of a top-secret innovation from the Halter atelier; in the spirit of “You Are There,” I will share it with you now.

I hope you’ve enjoyed the visit, and that you now have a sense of the wonderful, and completely unique, environment that produces the creative watches we’ve come to expect from Vianney Halter. Soot and clutter on one hand, elegant perfection on the other; a world of contradictions that only serves to increase my fascination with this watchmaker and his work.

For more information, please visit www.vianney-halter.com.

If you would like to learn more about Vianney Halter and other independent watchmakers, please check out 12 Faces of Time by Elizabeth Doerr.

Leave a Reply

Want to join the discussion?Feel free to contribute!

WAAAH Now I want an egg cup! And I don’t even eat boiled eggs…Also, that attic, yes please. His Goldpfeil is one of my ultimate ‘wants’. I’m fortunate to have been able to play with one. Love it.

I agree, Madam! That egg cup would be one of the great objects ever if it made it from blueprint to finished item. Happily, the Goldpfeil did make the transition, and I agree with you that it is a lovely piece.

Only bit of advice on the attic: if you go in winter, bring a heavy coat!

Thanks (as always) for reading and commenting,

Gary

Vianney Halter’s timepieces are sublime.

The innovative spirit and the technical prowess are breathtaking.

Now, if only the egg cup came with an equation of time indicator then it would really be something! Imagine timing your boiled eggs by it and comparing it to a sun dial! Horological nerd-ism doesn’t get much better!!!

Thanks for the article. Fascinating stuff.