When you pay attention to science and technology (and nerd out about the latest inventions), it isn’t every day that you are surprised by a new tech release. Usually the precursors and stepping stones along the way to a “breakthrough” have been on your radar for months or years, so when something comes along that is touted as the next big thing, you usually think to yourself, “I was wondering when that was going to be ready for the market . . . ”

A great example of this is the foldable smartphone, once a pipedream of futurists now it becomes a reality in 2019. Samsung is coming out with the Galaxy Fold and Chinese manufacturer Huawei is soon to release the Mate X, two different designs that see the very first commercially available folding screens. The products are impressive, and the function seems like magic if you didn’t know it was technologically possible before now.

But tech enthusiasts have been seeing foldable and flexible screens for years, with new prototypes showing up at the Consumer Electronics Show (CES) every January for a while now.

However, not every technological advance can be predicted, even by those keeping a professional eye on an industry. Thanks to their connections journalists may be aware of what’s coming, but sometimes the only people who know something is coming are the very people who have created it.

Then surprise makes an appearance along with the giddy delight of awe!

I felt this recently, and it proved to be a memorable experience as I was truly surprised by what I saw.

The day after the end of SIHH 2019, I visited a brand outside the show, LVMH darling TAG Heuer, and discovered that it had quietly released something new during the preceding Richemont fanfare that represented a significant technological advance for material science.

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph

The new tech is a patented carbon composite of carbon nanotubes and amorphous carbon, and it can be found in the balance spring of the brand-new Carrera Calibre Heuer 02T Tourbillon Nanograph, an incredible (and incredibly priced) piece of high-tech horology.

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph: the basics

The Carrera Calibre Heuer 02T Tourbillon Nanograph is based on the Carrera Heuer 02T launched in 2016, the first sub-15,000 CHF Swiss-made tourbillon on the market. The movement is a C.O.S.C.-certified manufacture automatic chronograph with a tourbillon, and it features a patented carbon-composite hairspring that TAG Heuer feels has proven itself better than silicon or the more traditional Elinvar alloy found in nearly every watch made today.

The case of the Tourbillon Nanograph is a combination of PVD titanium and forged carbon in the familiar Carrera style, but many of the small details have been modified to highlight the hexagon, the base the carbon atoms are arranged in at the atomic scale.

The exact formation of the carbon is key to the performance of the hairspring, which I detail below. The dial, case, movement, and strap also have bright neon-green highlights, visually tying everything together and adding a highlight color that has been popular with the brand in the past.

Aluminum balance wheel with lume on the TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph

Adding visual appeal, the aluminum balance wheel has Super-LumiNova applied to the rim so that along with other parts of the dial it glows in the dark .

The Carrera Calibre Heuer 02T Tourbillon Nanograph is the younger sibling of the original Carrera Heuer 02T from 2016, remaining somewhat similar in details and very similar when it comes to the base movement.

The largest technical differences are in the balance spring and balance assembly. The changes necessitated by the carbon-composite hairspring are significant, and the introduction of said hairspring is undoubtedly going to be one of the highlights of 2019.

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph: engineering a technical achievement

Why exactly is this new hairspring such big news?

If it was only due to the fact that engineering a new hairspring that is as reliable as what is currently in use (Elinvar alloy and silicon) is extremely difficult, this would still be a noteworthy achievement.

There have been a couple attempts historically at using carbon (specifically carbon fiber) for hairsprings, but nothing has taken off due to the lack of solving common problems and/or functioning consistently enough.

But the new carbon-composite from TAG Heuer takes a different direction, it utilizes the best features of silicon fabrication and carbon materials and combines them to manufacture a hairspring that not only improves stability, but can be manufactured at a scale that makes it plausible as a replacement to the other hairspring technology.

TAG Heuer designer Guy Bove holding the Carrera Calibre Heuer 02T Tourbillon Nanograph

The newly developed carbon-composite hairspring is based on carbon nanotubes and their incredible structural stability and lightness. Even though they are 96 percent empty space, carbon nanotubes are one of the strongest materials known to man.

The nanotubes are so empty and incredibly small that on any macro, or even micro, scale they lose their structural advantage and become weak. That weakness can be overcome if they are combined with another material that supports and protects their structure.

This is where the composite aspect comes in.

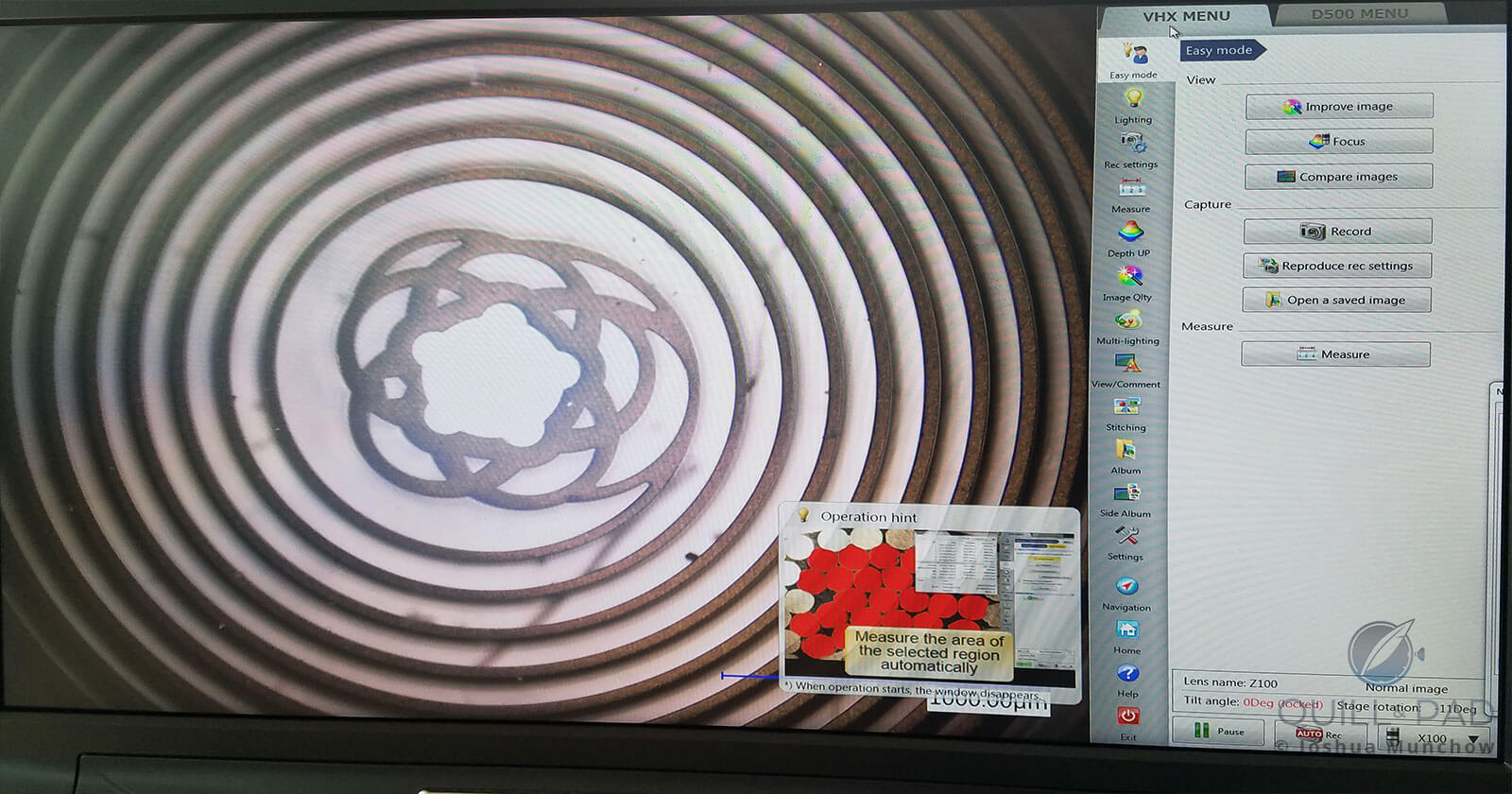

The hairspring is a composite of carbon nanotubes and amorphous carbon: the amorphous carbon is used to fill in the space inside and between the carbon nanotubes. The carbon nanotubes are first grown in a high-temperature environment comprising hydrogen and ethylene gas on top of silicon wafers that have been coated very accurately with iron atoms (a catalyst) in the exact shape of the hairsprings.

The wafers and gas are heated to 950°C (1750°F), which causes the ethylene gas to degrade, freeing the carbon atoms that attach to the iron atoms, growing a forest of nanotubes in the precise shape of the hairspring.

A nanotube is simply a cylinder made of a one-atom-thick hexagonal lattice that forms a perfect tube shape. The mixture inside the build chamber is then changed, and the resulting tubes are filled in with amorphous carbon that, thanks to very stable covalent bonds, produces a functional material that behaves like a polymer composite (which is very flexible and resilient) but has physical properties of a crystalline structure (which is very strong).

View through the display back to the hexagon-filled rotor of the TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph: development is a long road

The entire process is a specially developed form of CVD (chemical vapor deposition) that is normally used to grow silicon components like hairsprings and escape wheels. A pair of machines were developed specifically for this task by the TAG Heuer Institute, the research and development arm of the LVMH group’s watch brands.

Development has taken three years, with the process and material having been patented. The process has already been industrialized for production.

The silicon wafer on which the hairsprings are grown hold 330 individual springs that take roughly three hours to create. The production currently allows more than 100,000 springs to be made per year (if run to full capacity) at a cost similar to that of the traditional Elinvar alloy hairsprings.

Balance spring made of a carbon composite based on carbon nanotubes

This puts the new carbon-composite hairsprings in the running as a viable replacement if all other properties were equal. But they are not equal, and the carbon composite is oh, so much better.

The carbon-composite hairspring is 50 percent lighter than silicon with a density of 1.6 g/cm3 versus silicon’s 2.32 g/cm3. And it’s more than five times lighter than Elinvar, which has a density of approximately 8.12 g/cm3. This lightness, while keeping inertia values low, makes the hairspring less susceptible to disturbances.

That means it is extremely shock resistant, showing no deformation in a 5,000 G drop test while silicon hairsprings broke and Elinvar hairsprings bent.

Admittedly the material is a bit more thermally variable than Elinvar, but this is offset by pairing the spring with an aluminum balance wheel to counter the expansion or contraction at different temperatures.

Finally, the carbon-composite material is nonmagnetic, something that any steel-based hairspring can never claim to be. This makes it similar to silicon in that respect.

And while silicon and the carbon composite are both conductors and therefore may be temporarily affected by extremely strong magnetic fields (thanks to Lenz’s law), there is no risk of the hairspring or balance becoming magnetized and introducing continuous error like can happen with standard hairsprings.

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph on the wrist

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph: designed with intent

But the improved physical properties of the material over silicon and Elinvar aren’t the end of the story. Thanks to those physical properties, combined with the fabrication techniques, the carbon-composite hairspring can be designed specifically for the exact balance and frequency and elimination of nonconcentric expansion during operation.

With a shift from thin to thick at a specific length of the spiral, the spring can be designed to expand and contract perfectly concentrically to the balance pivot instead of off to one side as a result of the mounting position. The terminal curve, which is usually very critical to the spring’s proper function, is designed into the shape precisely, similar to that of a silicon example to ensure the correct expansion and contraction of the spring.

The mounting position of the spring is also variable thanks to the end of the spring’s ability to be attached to a micro regulator stud. This isn’t possible with silicon examples as they are designed (by necessity) to be free-sprung with no adjustment.

You can also adjust the frequency via adjustable masses on the rim of the balance wheel. This ability means that the hairspring can be utilized in both much higher end pieces and more mass-produced watches.

One of the biggest advantages of the new carbon composite is actually in easing assembly. The collet, which is normally a separate metal component added to the hairspring later, can be physically incorporated into the spring since it isn’t fragile like silicon.

Something Elinvar and other alloys can only dream of, this ability reduces possible errors or inaccuracy that could be introduced during the assembly of these components since it is made to perfectly fit the balance stem.

On top of that, the consistency of the spring and reduced number of steps speeds assembly and regulation time for watchmakers at the bench according to Guy Sémon, CEO of the TAG Heuer Institute, cutting up to 40 minutes’ time from regulating a chronometer, largely due to the ease of regulating the flat and vertical positions.

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph: do the math

Now, this might not seem like a huge deal for a small run of 20 ultra-high-end watches that might take months to finish, but in terms of mass-production watches, this change alone can speed up production times tremendously. In the time it takes to assemble and regulate just 100 watches, this can eliminate more than eight days’ of human effort, or nearly three months (12 weeks) of time over 1,000 watches.

Extrapolated out over an entire year’s production capacity of more than 100,000 hairsprings, this could translate into nearly 23 years (at eight hours a day) of manpower saved. While I am sure this is a high estimate from Sémon, even at ten percent of that estimate saving “only” an average of four minutes on regulation would still equal more than 6,500 hours saved during regulation and assembly.

These are the hidden benefits of inventions like this, the simple labor-saving costs that go above and beyond straight production cost.

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph

And, finally, the cherry on top of the carbon-composite hairspring sundae is that 100 percent of the production will receive C.O.S.C. certification, meaning every watch bearing the new carbon-composite hairspring will be chronometer grade.

It is hard to compete with an automatic chronograph tourbillon chronometer priced at $25,500, just over 10,000 more than the original Carrera Heuer 02T. This invention and pursuit of innovation is a clear indication that TAG Heuer is serious about creating top-quality watches at prices much more accessible than what some might assume for this type of technology.

In a way it is akin to how Rolex invests so much capital on improving every component of its watches little by little in trying to create truly functional timepieces that continually remain competitive.

This development from TAG Heuer could help the brand, and all of LVMH, inch into the lead when it comes to technologically advanced mechanical watches available to the general public.

Brands are supported by the highest volume, lowest cost pieces, so making those pieces better makes the entire brand better. This new carbon-composite hairspring is just the right amount of technical awesomeness combined with mass-market usability.

The style of the Carrera Calibre Heuer 02T Tourbillon Nanograph is interesting: very industrial and packed with details.

TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph

But the style almost doesn’t matter since it is a showcase for the technology, and once it starts being incorporated into other timepieces, it will be like the silicon hairspring, a barely noticeable addition that fundamentally changes the technical achievement inside the movement.

This development was a surprise to me, and while it makes total sense in hindsight I never saw it coming. That makes this an enjoyable experience in a personal sense, and my time handling the Carrera Calibre Heuer 02T Tourbillon Nanograph was a highlight of my January in Geneva.

I’ve built it up, now let’s break it down!

- Wowza Factor * 9.25 The watch is visually interesting to be certain, but nothing wows more than the tech behind that hairspring!

- Late Night Lust Appeal * 92.5» 907.115m/s2 Given how light that hairspring is, this watch packs quite the punch, keeping you up till all hours of the night!

- M.G.R. * 68.5 The movement is already pretty geeky considering the price point, but newly invented tech always kicks things up a notch!

- Added-Functionitis * Moderate A chronograph is a serious complication to be sure, but since there is no date, power reserve, or other random complication this piece still runs in the middle of the pack of complicated watches. Of course you still need regular-strength Gotta-HAVE-That cream for the ultimately technical swelling.

- Ouch Outline * 10.2 The existential pain of questioning the purpose of loss! I like philosophy, and lately I have been pondering some big questions. When that combines with real events of a tragic nature, things can get nihilistic fairly quickly. But passions can help us regain our hope, and a fabulous watch with awesome tech tickles more than a few passions.

- Mermaid Moment * The hairspring is what?! Sometimes the only thing needed to make you say “I do” is the discovery of just what makes the object of your affection tick. Literally!

- Awesome Total * 637.5 Start with the price of this watch U.S. dollars (25,000) and divide by the water resistance in bar (10), then divide the result by the frequency of the balance in Hz (4) and the result will be a technically awesome total!

For more information, please visit www.tagheuer.com/en-us/watches/tag-heuer-carrera-calibre-heuer02t-nanograph-automatic-chronograph.

Quick Facts TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph

Case: 45 mm, black PVD titanium and forged carbon

Movement: automatic Caliber Heuer 02T with in-house carbon-composite hairspring, one-minute tourbillon, C.O.S.C. chronometer certification, 65-hour power reserve, 4 Hz/28,800 vph frequency

Functions: hours, minutes, seconds; chronograph

Price: $25,500

Remark: comes with integrated watch winder in packaging

You may also enjoy:

Belts, Belts, Belts. And The TAG Heuer Monaco V4 Tourbillon

Focus On Technology: Plastics In Watches And Why We Are Likely To See More Of Them

Trackbacks & Pingbacks

-

[…] am articulate about a carbon-composite hairspring that debuted in Jan 2019 in a Carrera Calibre Heuer 02T Tourbillon Nanograph for $25,500, a reward position for […]

Leave a Reply

Want to join the discussion?Feel free to contribute!

This is very cool and exciting, although I am not a fan of the design of their first watch with this spring. However I see everyone repeating the press release as if it were independant testing, which it is not. Of course silicon spiral springs can sustain 5000g: they are used on Omega sport watches for instance. The ISO norm for a shock resistant watch is a 1m drop on hard wood, which for an average-weighed watch corresponds roughly to a 5000g acceleration. Sport watches (and actually, all watches except maybe exotic complications) by big brands are always qualified as shock resistant.