The Omega Spirate System: A New Idea in Balance Spring Technology

Justin Koullapis is the technical editor of the Horological Journal (HJ), the magazine of the British Horological Society, in April 2017. This article was first published in the HJ in the September 2023 edition and it is republished here with permission. Images are from Omega.

The HJ is the oldest continuously published technical journal in the world. First published in September 1858, it has appeared monthly ever since – without fail.

————————————–

The Omega Spirate is a new balance spring system that can be adjusted for stiffness to allow fine adjustments of the rate to within 0.1 seconds per day. This is one of the few truly new ideas in horology made possible by silicon manufacturing techniques.

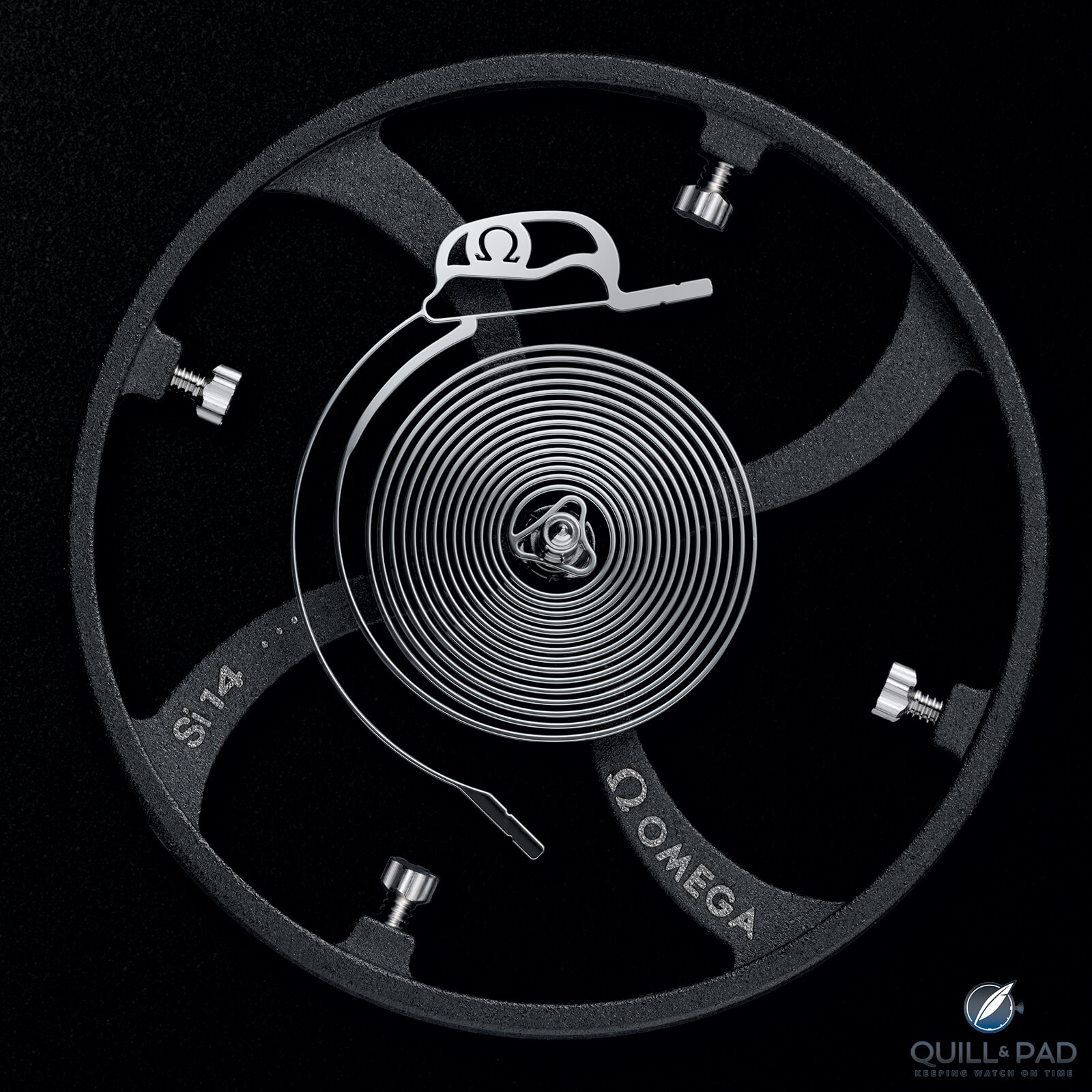

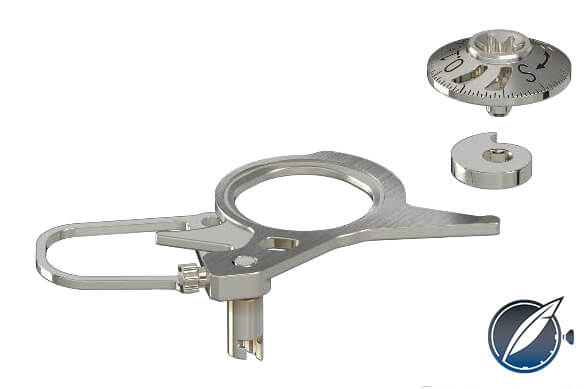

Omega Spirate balance

The system was announced in January this year. However, technical details were sparse, with Omega supplying only basic images of the spring and views of the watch into which it’s installed, the new Speedmaster Super Racing.

Recently Omega invited the HJ to a technical conference on the Spirate from which this exclusive report has been prepared.

When the Spirate was announced, an informal conversation arose between Jim Arnfield, David Boettcher, Martin Foster, Anthony Randall, Tim Treffry and me. Little by little the conversation honed in on how the system works.

Our conclusions were verified at the press conference and, in particular, we are grateful to David Boettcher for his detailed technical analysis.

Figure 1. The Spirate balance spring. The Loading Beam Tip can be moved left or

right to introduce tension or compression at the Blade, altering the rate of the watch.

The Spirate has at its core a flat balance spring with unusual features, depicted in Figure 1. The body of the spring proper terminates at a flexible flat blade rather than at a more usual stud. The whole arrangement is in turn fixed to a stud with the short arm pointing to the right.

The general principle is this: the overall ‘stiffness’ of this balance spring is a combination of the stiffness of the spiral part and the stiffness of the blade.

This overall stiffness directly affects the oscillator’s period, (the rate of the watch). By subtly altering the stiffness of that short blade, the watch rate can be adjusted extremely finely.

————————————————————————————————————–

—————————————————————————————————–

There is some new terminology. Terms in bold type are from Omega; the others are our own:

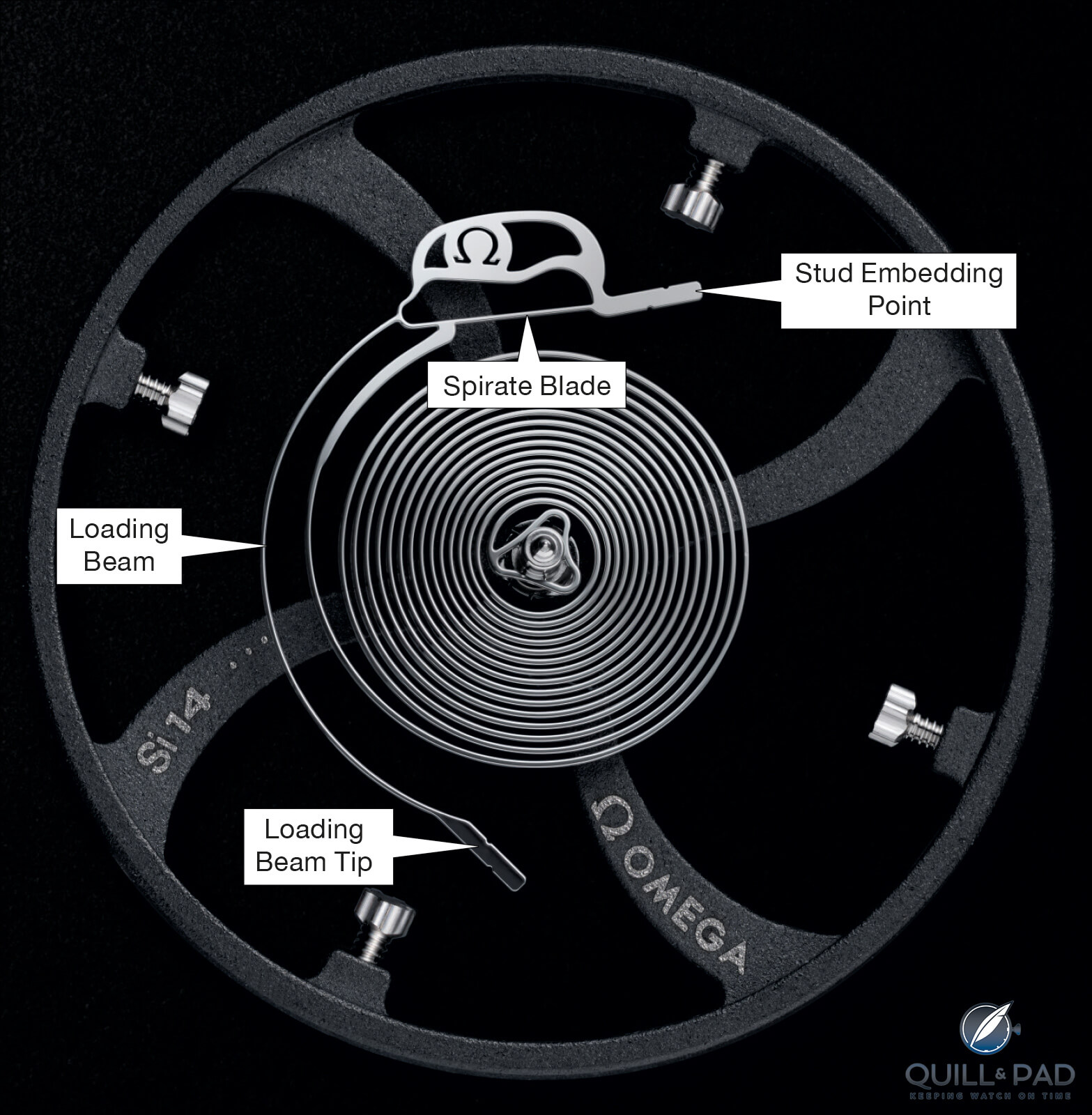

In Figure 1, there is the Loading Beam. This can be moved slightly left or right. At its free end is the Loading Beam Tip. This is held in the lower of the two studs shown in Figure 2.

Figure 2. As seen on the rear cover, but with the Blocker removed, showing the

anti-backlash horseshoe spring to the left, acting on the ‘Rate Mobile Stud Holder’. This can be moved by a snail concealed under the calibrated Tuner at the right.

The upper end of the Loading Beam terminates at the part shaped like an archer’s bow. This rigid bow hardly flexes, ensuring that any motion of the Loading Beam is directed at introducing tension or compression into the Blade.

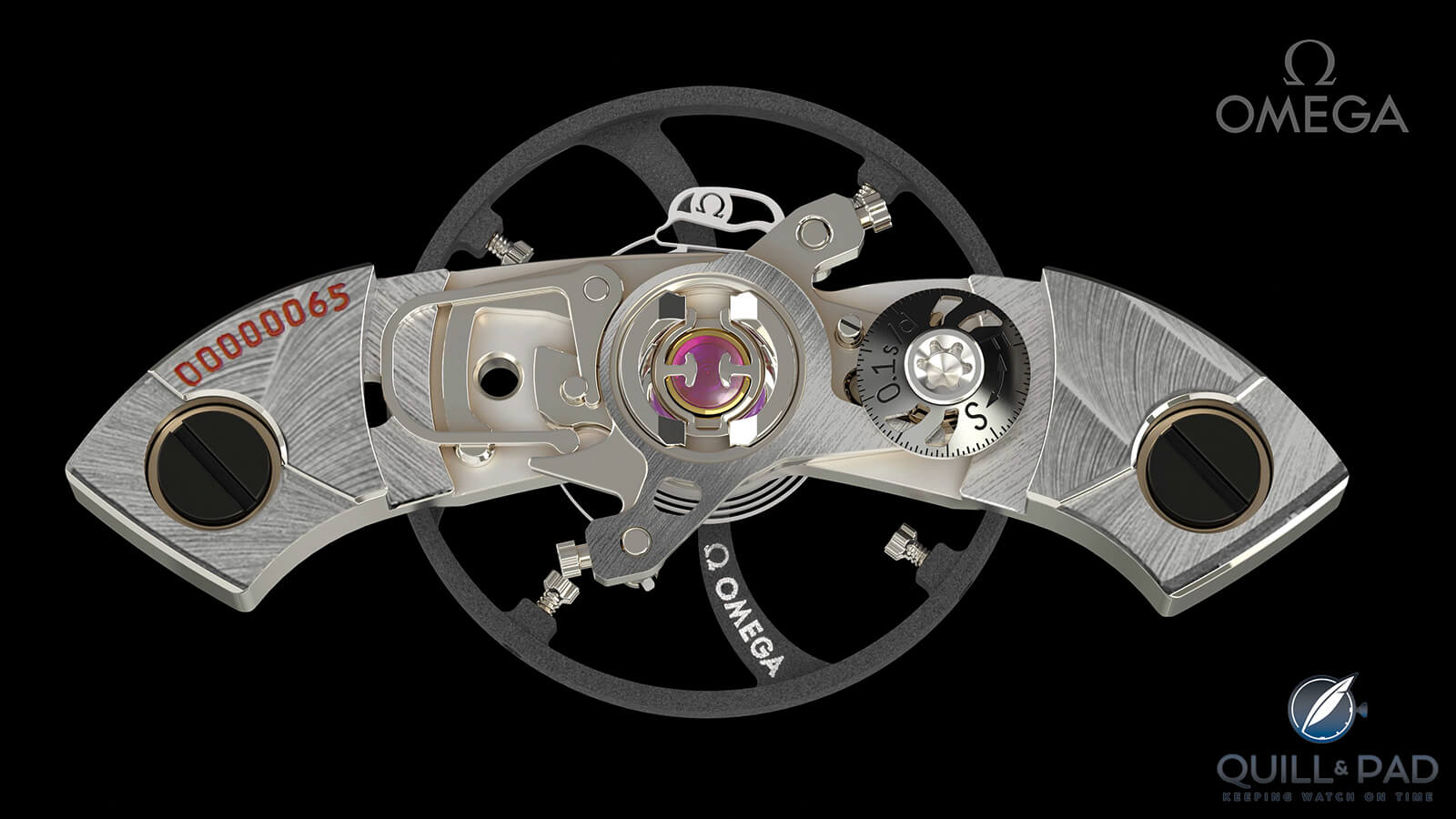

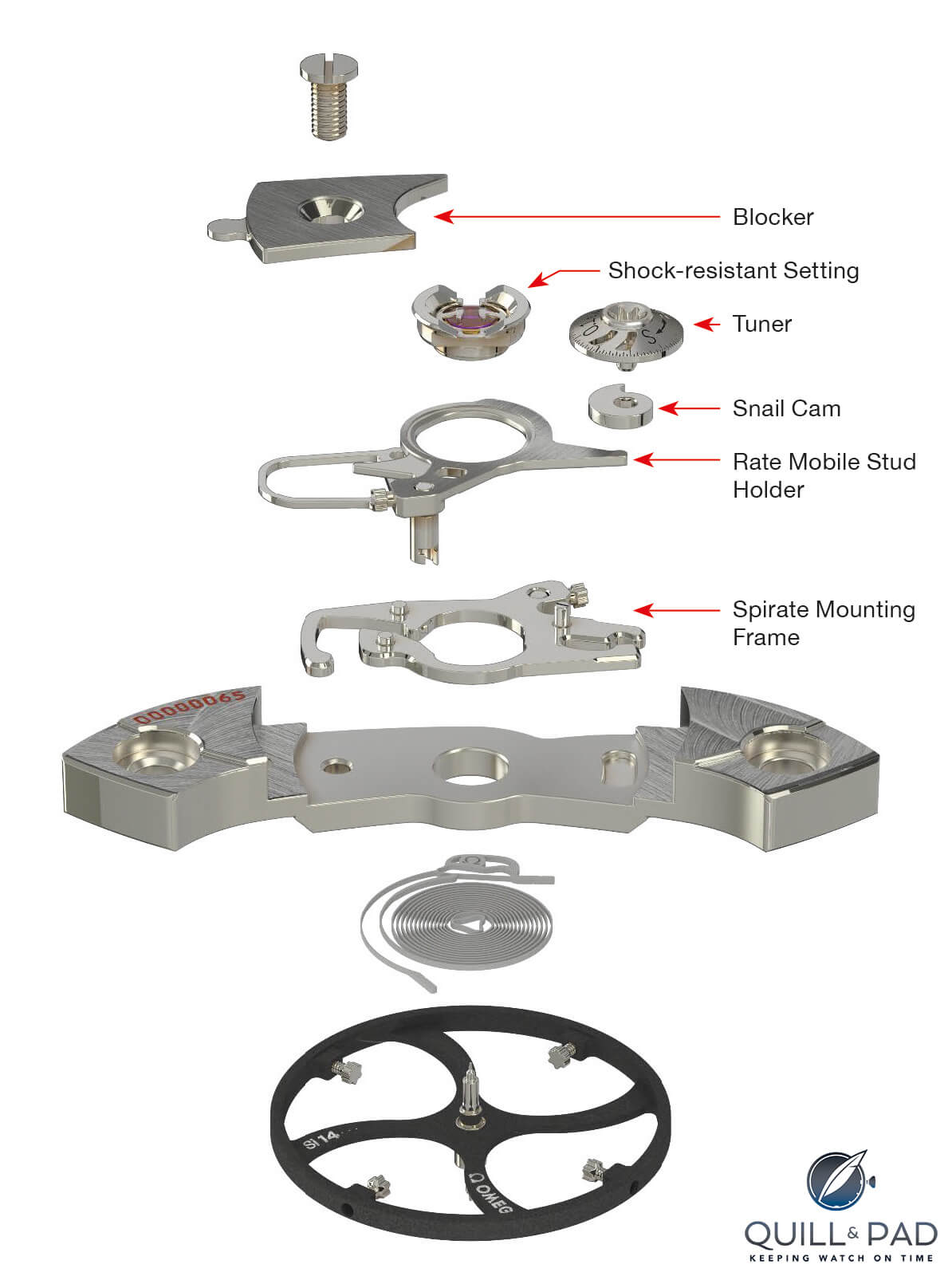

Figure 3. The relative positions of the system components in exploded view.

The mounting frame can be moved for beat adjustment.

Adjustment is made by rotating the calibrated Tuner, Figure 3. This rotation (via the Snail Cam, normally hidden from view) causes the Rate Mobile Stud Holder, to rotate slightly. It carries the stud referred to earlier, which in turn holds, and moves, the Loading Beam Tip.

The whole spring is attached to the watch by the Stud Embedding Point, which points rightward near the top. This is held rigidly in the upper stud. The entire assembly can be rotated to put the watch in beat.

Figure 4. Details of the Spirate calibrated rate adjustment. The Rate Mobile Stud Holder follows the snail cam’s motion. The stud descends below the cock, grasping the tip of the balance spring’s Loading Beam.

The Rate Mobile Stud Holder, the Snail Cam, and the calibrated Tuner are shown in more detail in Figure 4.

The Rate Mobile Stud Holder as depicted in the photos of the watch has a +/- engraved onto it (although it’s not shown in the exploded views). This was quite a red herring when we tried to analyze the Spirate early on because it seemed that the associated fluted-head screw was some type of adjuster.

The +/- is only an emblem, indicating that the whole part moves to alter the rate. The fluted-head screws here and on the opposite side are simply clamping screws to hold the studs in place.

There are notches in the spring’s Stud Embedding Point and the Loading Beam Tip. These are for mechanical gripping within the studs, which is more sure than glue with this material. The spring is made by Deep Reactive Ion Etching (DRIE) of oxidized monocrystalline silicone, at Asulab, Swatch Group’s research and development laboratory.

You can visualize from Figure 4. how the Tuner is keyed to rotate as one with the Snail Cam. The rightmost limb of the Rate Mobile Stud Holder is a cam follower, pressed into permanent contact by the action of the horseshoe spring visible to the left in Figures 2 and 4.

As the Tuner is rotated, the snail causes the Rate Mobile Stud Holder to pivot slightly around the shock-resistant setting, flexing the Loading Beam slightly left or right.

—————————————————————————————————–

—————————————————————————————————–

At the press conference, Omega played a short animation of the system in action. By analyzing that footage, I estimate that the total range of motion of the Rate Mobile Stud is about 7.8 degrees for a full rotation of the Tuner/Snail.

A full revolution of adjustment can effect a 10 second rate change with a resolution of 0.1 seconds. More specifically, from the neutral point of the Loading Beam, it can alter the rate by 5 seconds each way.

Notice that the shallowest part of the snail is undercut under the step. This allows for the cam follower to tuck right under the snail’s highest point – this means that the tuner can be adjusted through a full 360 degrees (although it can’t obviously make continuous full revolutions in both directions without being reversed).

Omega imposes an absolute rate limit on this watch of +1 second per day.

How is Regulation Achieved?

To summarise: At factory assembly, the watch is first put into beat by loosening the Blocker, rotating the entire assembly until the escapement is on the line of centers. Functionally this is similar to the ETAChron system.

The Blocker is then fastened. This locks the beat position and prevents accidental change to the beat when the Spirate is adjusted.

General regulation by modifying the moment of inertia is next applied via adjustment of the micro-regulation screws in the balance rim, taking care to maintain poise.

Figure 5. Lobed adjusting tool.

The final regulation is then applied by twisting the calibrated Spirate Tuner using the matching tool, Figure 5. When the Tuner is turned anti-clockwise, it introduces tension into the Blade, increasing the frequency of the oscillator, and vice-versa.

Reviewer discussions raised the possibility of variable side-loading of the balance pivots when the Loading Beam is moved. Omega assures us that this doesn’t come into play at all, because the stiffness of the ‘archer’s bow’ means that all the motion at the Loading Beam’s tip strictly goes into introducing tension or compression at the Blade.

There is no shift in the position of the spiral part of the spring. They say that there is no visible change in the shape or position of the Blade – only its tensile state is altered.

Questions were also raised as to whether there is any isochronal effect, where long and short arcs might be affected differently by the changes in tension at the Blade.

Any potential such effects must be vanishingly small because the long duration of this self-winding watch (60 hours) and the exceptional quality of modern mainsprings mean that low amplitudes are likely seldom encountered.

—————————————————————————————————–

—————————————————————————————————–

David Boettcher FBHI, who wrote a comprehensive treatise about balance springs in 20181 considered this question and wrote a brief paper on it; his analysis was confirmed by the information presented at the Omega technical conference.

The following sub-section is a summary of that paper.

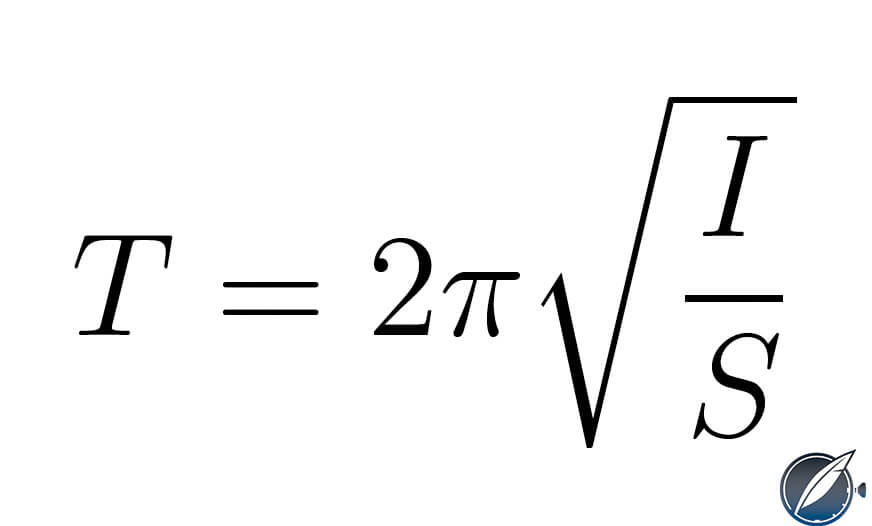

The general equation for the natural period of oscillation T of a balance-spring oscillator is

Here I is the moment of inertia of the balance and S is the spring constant of the balance spring. David suggested that since the Omega Spirate allows this to be varied, it would be better here to call it the spring stiffness.

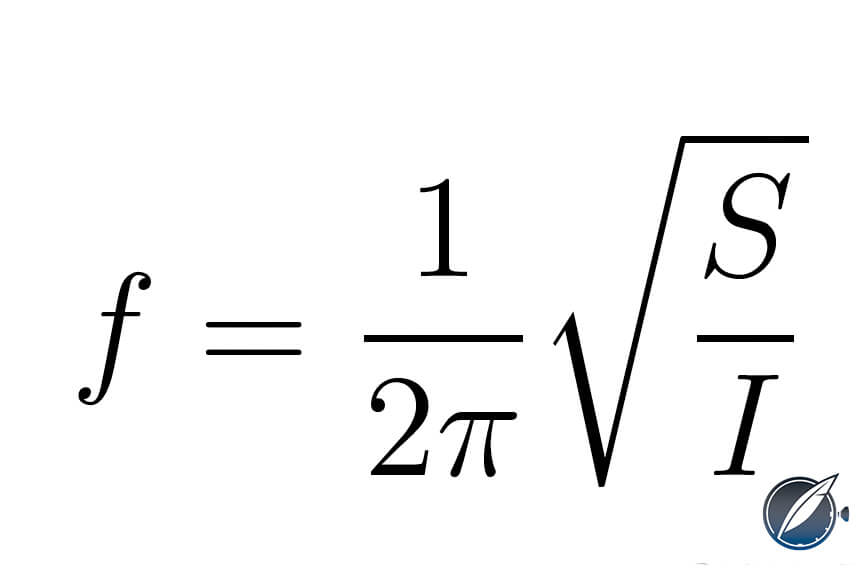

Inverting the equation to obtain frequency we get

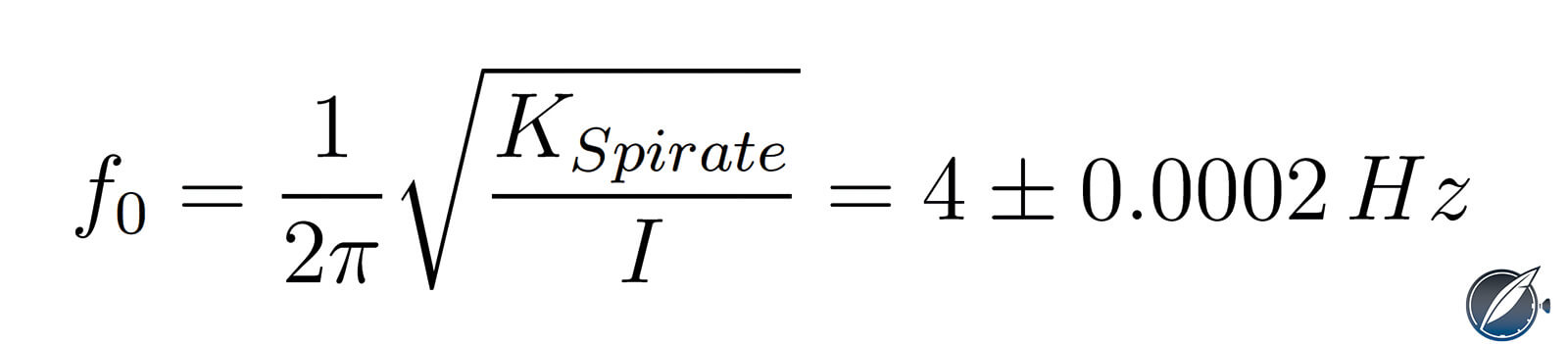

At the conference,Omega showed the expression for frequency as

where KSpirate is used instead of S for the spring stiffness. The subscripted f0 refers to the base frequency of 4 Hz (28,800 vph), with a variation of +/- 0.0002 Hz or just over 4 seconds per day. This suggests that the overall balance spring stiffness KSpirate can be adjusted.

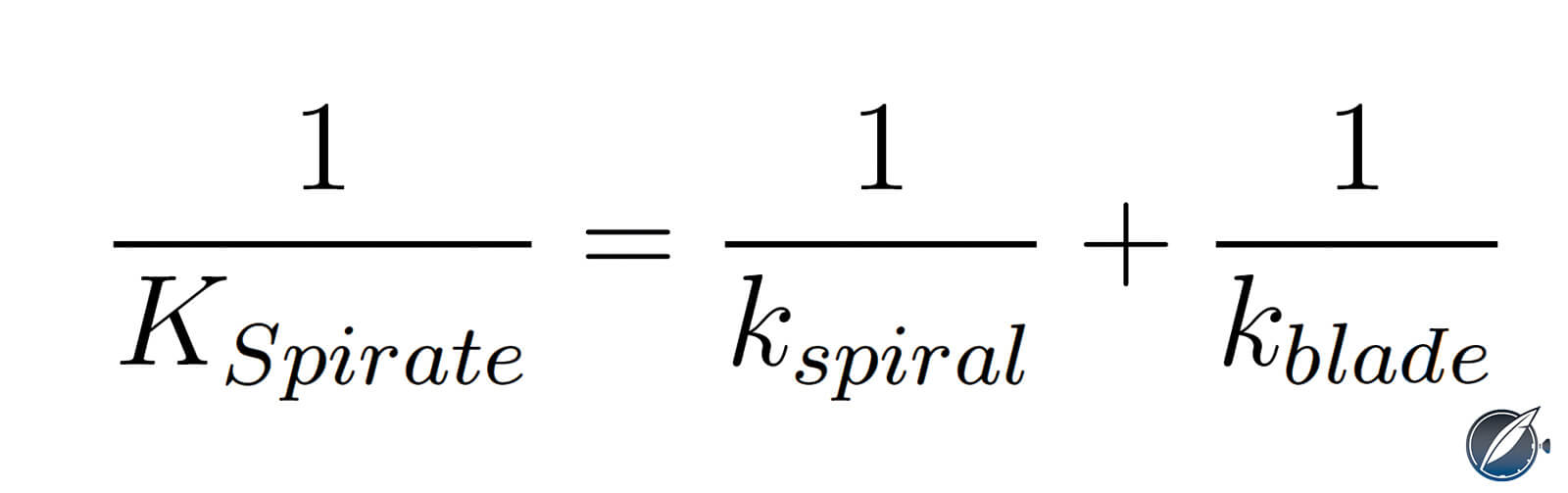

Omega then expanded the subsidiary expression to

which shows that the total stiffness of the spring can be considered as the sum of two components: the conventional spiral part of the balance spring and the ‘Blade’.

—————————————————————————————————–

—————————————————————————————————–

We now know that by using the Spirate, Omega seeks to adjust the stiffness of the blade part of the system, not the spiral part. It does not require a large change to achieve the small variation of +/- 0.0002 Hz.

The mechanism for changing the stiffness in the Blade has been described above, by applying variously a tensile or compressive force upon it by altering the position of the Loading Beam.

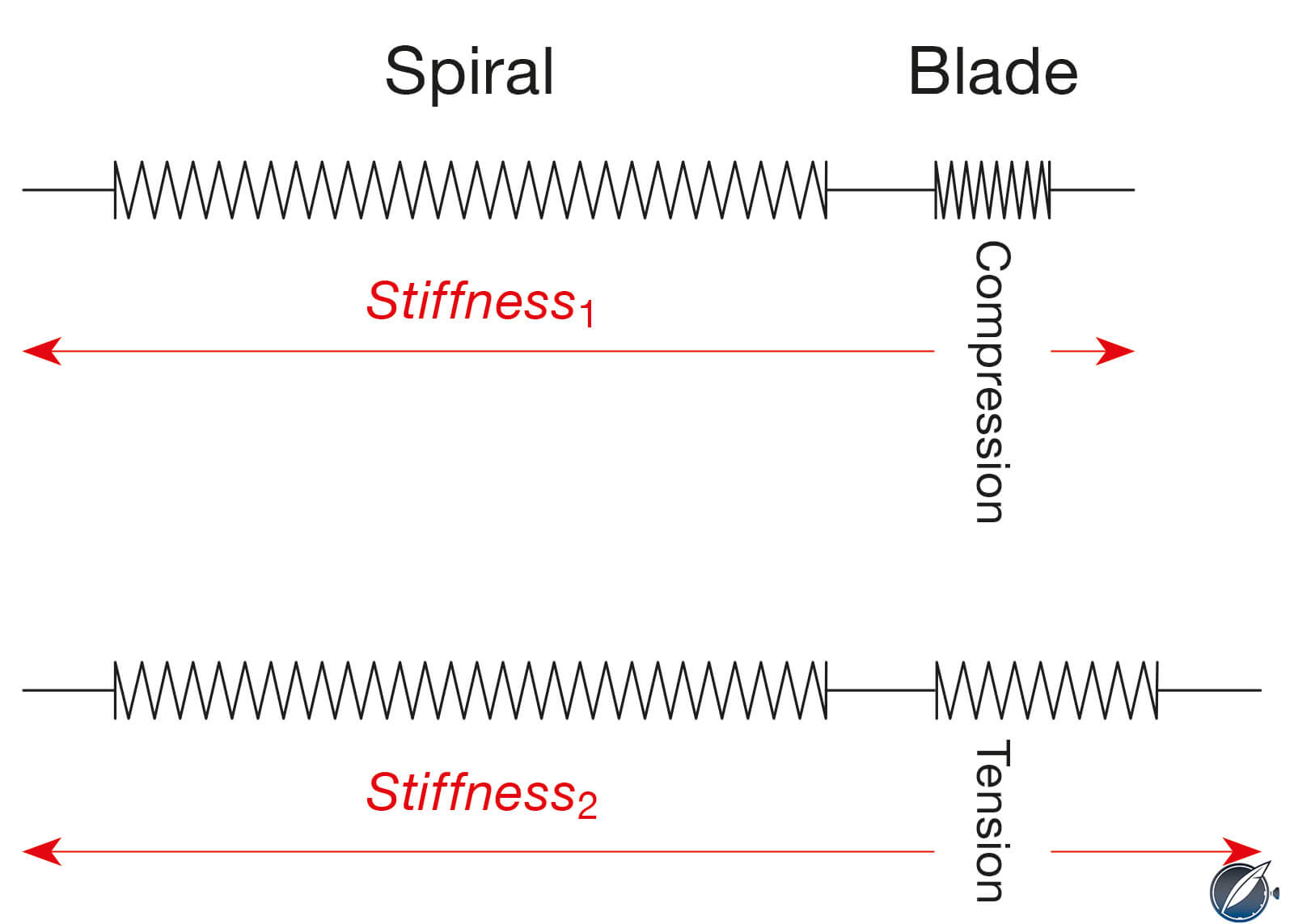

Figure 6. The stiffness of the balance spring’s spiral and Blade

components separated out. With the Blade in compression, spring overall stiffness is lower than with it in tension.

Omega showed a sketch similar to the upper part of Figure 6, demonstrating how the overall stiffness of the system is made up of two parts. David Boettcher had independently drawn an expanded version, from which we derive this figure.

This illustrates the two parts of the spring separately. It shows how the stiffness of the spiral part of the balance spring is constant, but that the Blade can be adjusted, altering the total stiffness of the system. When the Blade is in compression, the overall stiffness is lower than when in tension.

Low stiffness (compression) results in a lower relative frequency compared to when the blade is in tension.

Advantages of the Spirate System

Omega cites the following seven advantages of this system:

- Dynamic adjustment – adjustments can be made while the balance is oscillating (as opposed to having to stop it to adjust micro-regulation screws). This saves time as otherwise, the adjuster has to wait for the amplitude to settle before taking a fresh reading.

2. Adjustment is by a direct scale, on the calibrated tuner, as opposed to an indirect scale on a micro-regulation screw adjustment tool.

3. It is sensitive yet predictable.

4. Easy to use; adjustments can be made for clients in a boutique rather than having to send the watch to a service center.

5. Adjustment is fast – just one simple step. Here, Omega possibly revealed a potentially interesting figure. This rapidity of regulation, they said was important “…when you produce thousand (sic) watches a day.” Perhaps something was lost in the Swiss accent, or perhaps it was a statement of fact regarding their production figures.

6. No risk of adding an imbalance (out of poise), as sometimes happens with a free sprung balance and micro-regulation screws.

7. No contact is made with the oscillator. This diminishes the risk of damaging the balance bridge, bending or breaking the balance staff pivots, dislodging a shock absorber, and reduces the risk of leaving scratches.

—————————————————————————————————–

—————————————————————————————————–

When the Speedmaster Super Racing was announced, I was excited to see a new technical development but was initially frustrated by lack of information.

Omega Speedmaster ‘Super Racing Co-Axial Master Chronometer Chronograph’. 44.25 mm. Highly anti-magnetic

Calibre 9920 resistant to 15,000 gauss. UK RRP £10,700.

Our reviewers’ comments echoed this sense that there ought to be close cooperation between the world’s oldest technical journal of its kind and the industry.

Comments included:

‘I don’t think it possible to explain how the system works without more detailed information. Without that, I would not publish in HJ until we know more.’

‘I would like to see in HJ a clear explanation of how this system works with a close-up diagram … of the stud assembly showing how the adjusting screw acts on the spring.’

Omega Super Racing Tachymeter

One reviewer wrote that too many, or all, current watch articles on the web simply ‘reproduce the guff produced by watch industry PR departments … The spring’s complex outer terminal geometry, presumably the essence of the device, requires explanation. The reader needs to be able to understand the innovation, not just marvel at it. HJ is a technical journal, not a consumer magazine.’

In the end, Omega was more than forthcoming in information. Both Gregory Kissling and Sarah Nunziata of Omega and Swatch Group are to be thanked for their time and help.

View through the caseback to the movement of the Omega Speedmaster ‘Super Racing Co-Axial Master Chronometer Chronograph

Many applications for silicon watch components have been produced since 2001. Almost all of them are essentially just interesting new ways of making old things. We have silicon balances, pallets, and balance springs. However, the Spirate is one of the very few applications that is completely new2.

What’s more, it’s in a watch priced at the modest end of the luxury market, and Omega promises to roll it out into many more models. This isn’t just a flashy concept piece, it is a practical advancement capable of improving horology more widely.

The Spirate is a profoundly different idea that takes horology in a fresh direction, impossible with previous manufacturing methods. For this Omega should be commended.

Omega Super Racing dial details

For more information, please visit www.omegawatches.com/en-us/watches/speedmaster/two-counters/super-racing/product.

You can learn more or subscribe to the Horological Journal at https://bhi.co.uk/hj/

Sam Law-Bartle did the original layout for the article in the HJ. You can see that at https://quillandpad.com/wp-content/uploads/2023/12/HJ-September-2023-Spirate.pdf

References

David Boettcher, ‘Balance Springs, Part 1’, Horological Journal, vol. 160 (September 2018), p401.

Some of the more creative examples (in this author’s opinion) are:

- The Constant Escapement by Girard Perregaux

- The Ulysse Nardin Silicon Anchor

- The ‘Double Hammer’ FlexMEMS and Siloscape escapements by CSEM; the former may be related to the Grasshopper.

- The Genequand Regulator by CSEM/Vaucher/Pamigiani, followed by variations on that idea including various silicon oscillators by the Dutch startup Flexous, including for Zenith and Frederique Constant.

* This article was first published 09 December 2023

You might also enjoy:

Girard-Perregaux Neo Constant (Force) Escapement: The Evolution of a Revolution

Omega vs. Rolex: How Omega is Reaching for the Crown

Leave a Reply

Want to join the discussion?Feel free to contribute!

I love omega!!!!