Why Do Ultra-High-End Watches Cost So Much? Hand-Finishing At Romain Gauthier Sheds Some Light

by

My colleague Elizabeth Doerr recently published a very well appreciated article entitled How Does Nomos Glashütte Make A Beautiful Watch With Manufacture Movement For Under $3,000?

In this article, though, I look at the other extreme using the example of movement decoration: why do high-end watches cost so much?

There are quite a few reasons, including low production numbers (mass manufacture brings prices down) and high complexity, but the one I will focus on here is hand-finishing.

I decided to concentrate on hand-finishing because, unlike the terms low production numbers and high complexity, ultra-high-level hand finishing is not usually that easy to appreciate. Lots of press releases mention the high level of finishing and decoration, yet to the untrained observer a nicely finished movement in a $5,000 watch can look very similar to a superlatively finished movement in a $500,000 watch (not that the watch featured here costs quite that much).

One other thing to note is that hand-finishing at the highest level is not something that everyone can do (well) given enough training. It requires very high levels of dexterity that training can augment, but not instill.

To highlight why ultra-high-level hand finishing costs so much − or to put it marketing terms “adds so much value” − I would like to take a look at a few of the hand-finished components from one of my favorite watches of the last few years: Romain Gauthier’s Logical One.

Logical One by Romain Gauthier

Romain Gauthier’s Logical One has many qualities that make it such an exceptional timepiece − that’s not just my opinion, Logical One was selected as the Best Complicated Watch at the 2013 Grand Prix d’Horlogerie de Genève. These include a completely reinvented chain-and-snail-cam constant force system and push winding. However, the quality we will look at here is its ultra-high-end hand-finishing.

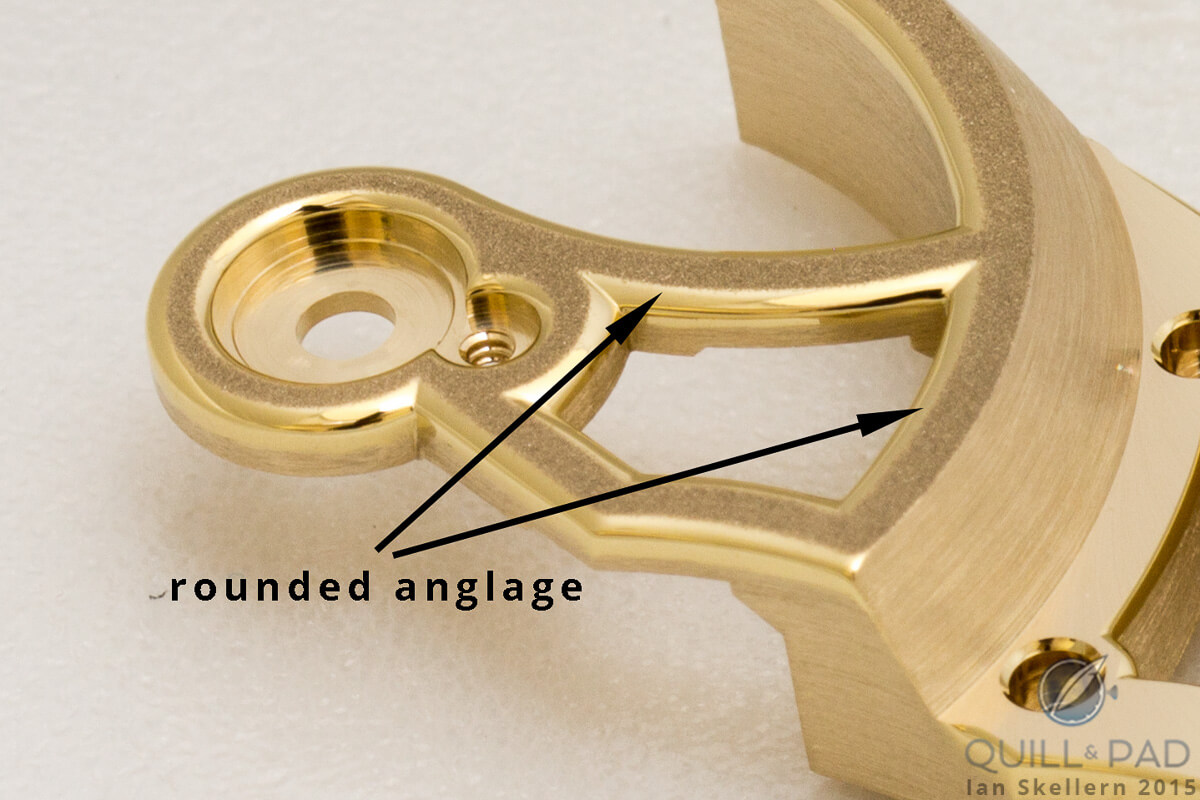

Romain Gauthier is one of only two artisans I know of using rounded anglage (the other is Philippe Dufour); also note the perfect inside angles here

Romain Gauthier is only one of two artisans I know of − the other being Philippe Dufour − that hand-finishes anglage with curved, rather than straight, chamfers. Please note that anglage is a type of finish, not a process (anglage = polished chamfer). On the photo above, we also see the inside angles that are extremely difficult to get just perfect.

Time is money

Switzerland is an expensive country to live in, and wages are correspondingly high. When it comes to manufacturing anything at all − and that includes watch components − time is definitely money. So imagine a component that has been manufactured to incredibly precise tolerances and could be used in a movement as is; then imagine spending days and weeks and months chamfering, shaping, decorating, and polishing to an incredibly high level that few will see and fewer still will appreciate.

This image shows where two of the components visible on the back of the movement fit on Romain Gauthier’s Logical One

Lower constant force bridge (15-17 hours)

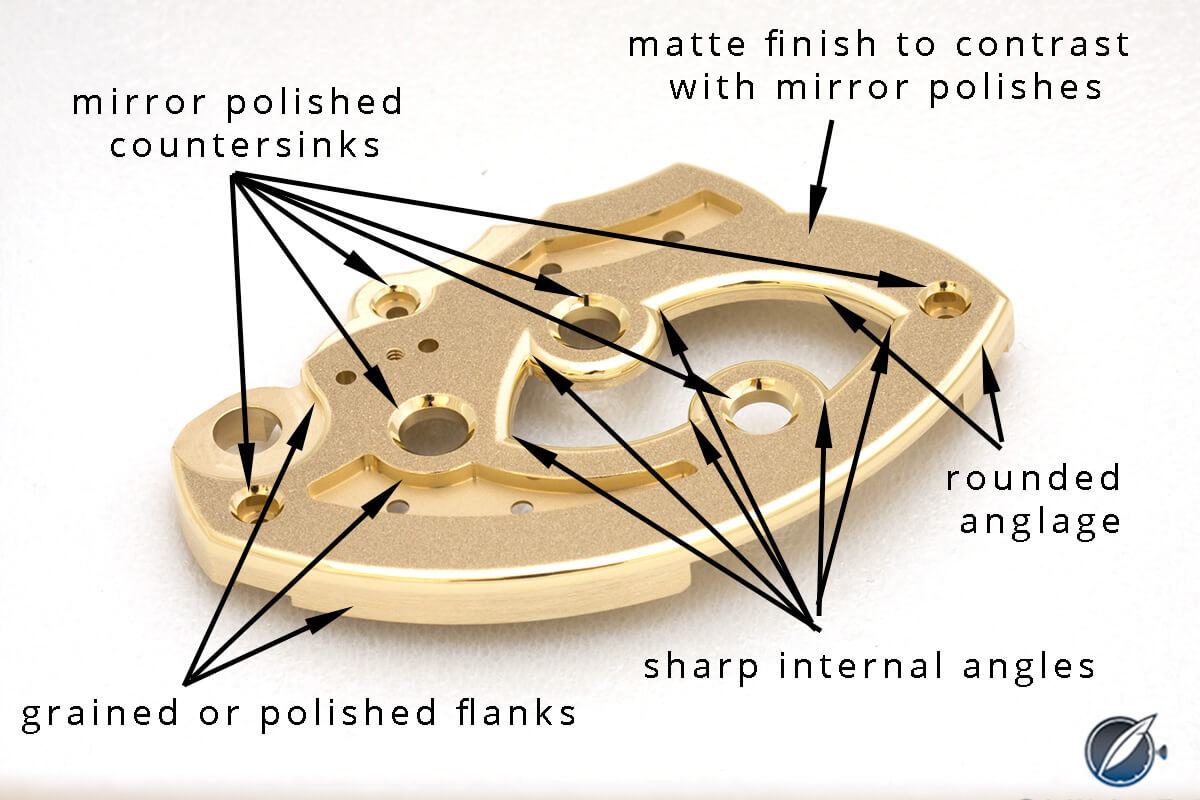

This bridge, which is the lower support for the constant force mechanism seen on the dial side, is quite complicated and has many high-end finishes applied to it. So it may not be surprising that it takes a full two days to hand-finish.

Just a few of the critical points that have to be carefully hand-finished on this lower constant force bridge for Romain Gauthier’s Logical One

The vast majority of mechanical movements can be fully assembled in less time than it takes to hand finish this one component. And there are many more.

This bridge supporting the mainspring barrel is normally visible through the display back of the Romain Gauthier Logical One

Mainspring barrel bridge (15-20 hours)

The process for taking the raw mainspring barrel bridge through to becoming a hand-finished component ready to grace a Logical One movement involves the following steps: pre-graining (making matte) the upper surface; filing the chamfers; completing the internal angles; shaping the curved arms leading from the attachment hole; polishing the filed surfaces to remove any traces of the filing; polishing the countersinks; making the flanks (vertical surfaces) clean and smooth.

The underside of the mainspring barrel bridge of the Romain Gauthier Logical One is finished as carefully as the visible side

This one component takes between two and three days (15-20 hours) to hand-finish

This image shows where two of the components visible on the dial side fit in Romain Gauthier’s Logical One

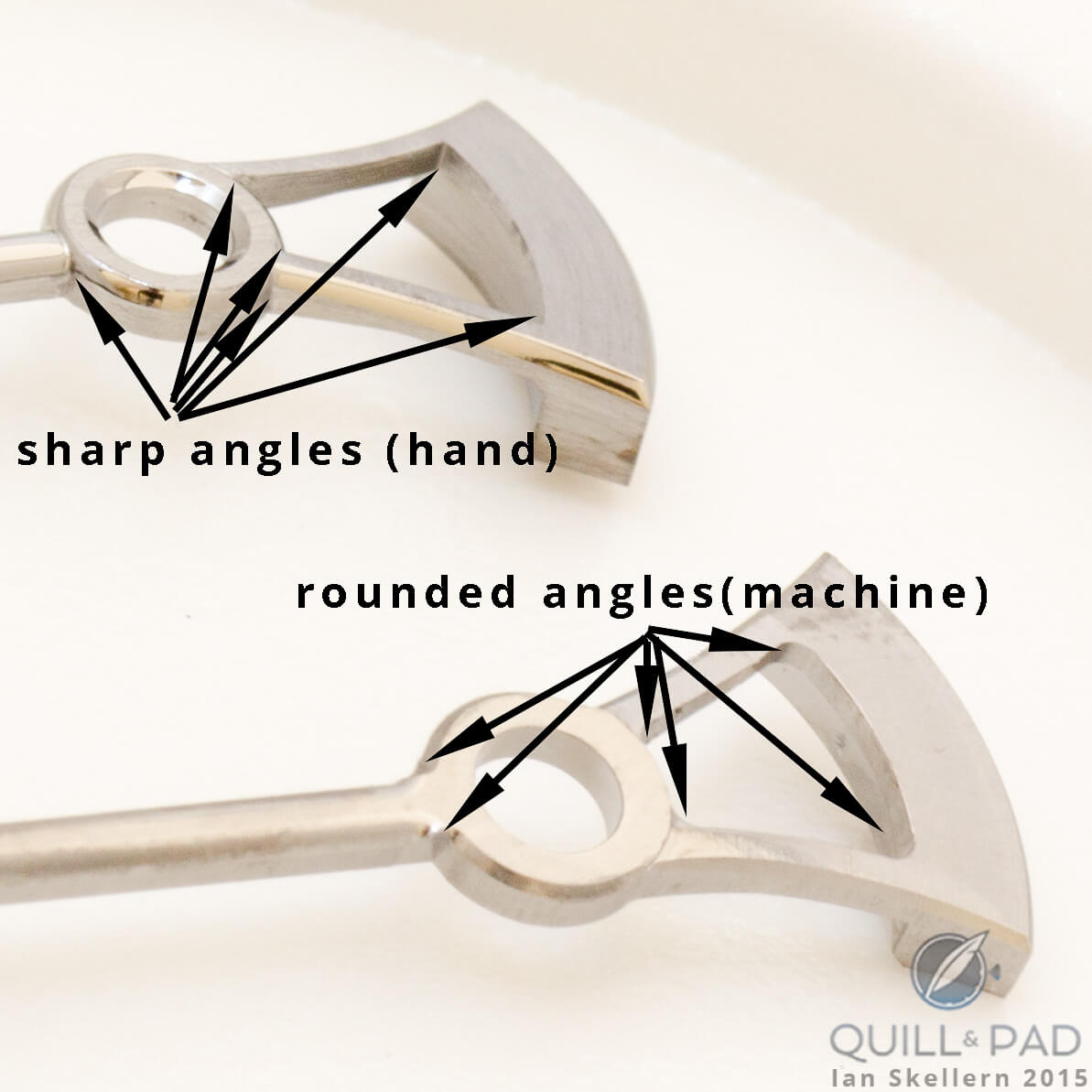

Balance bridges of the Romain Gauthier Logical One before and after: straight from the machine (left) and after three days of hand-finishing (note that the black “marks” are reflections from my camera)

Balance bridge (20 hours)

This distinctively-shaped bridge supporting the balance is visible on the dial side and is a particularly intricate piece to hand-finish because of those curved arms leading from the attachment hole. It takes a lot of time to file and polish those rounded curves, while the internal angles as always are difficult.

Balance bridges of the Romain Gauthier Logical One before and after: straight from the machine (top) and after three days of hand-finishing (note that the black “marks” are reflections from my camera)

When hand-finishing this piece, careful attention is needed to avoid deforming it as it is quite small.

It takes three full days to hand-finish this one component.

Hand-finishing on this upper constant force bridge for Romain Gauthier’s Logical One makes all the difference

Upper constant force bridge (25-30 hours)

The upper constant force bridge, which is clearly visible on the dial side, looks to be one of the simpler pieces to finish, but in fact it is the most difficult. Certainly in terms of time required.

First of all, the bridge is titanium, which is much harder than brass. Titanium is harder (as in the opposite of soft) to machine, harder to file, and harder to polish.

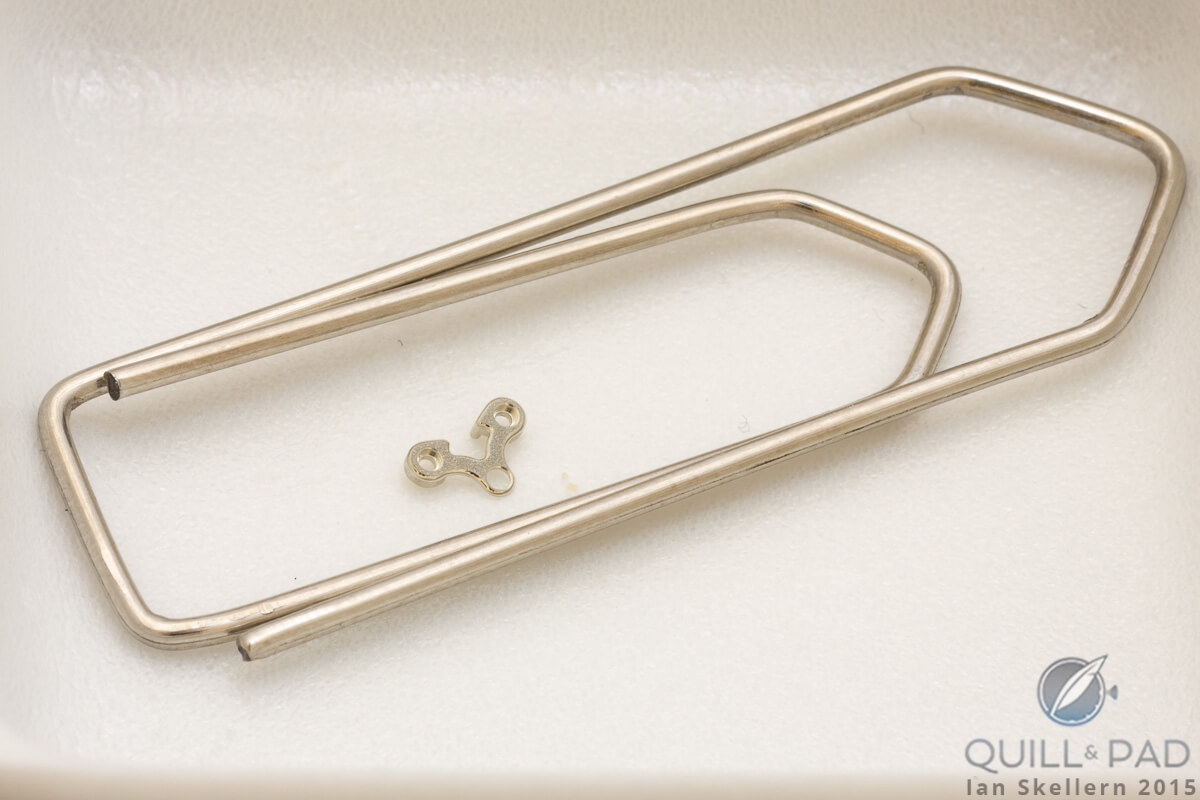

Titanium upper constant force bridges of the Romain Gauthier Logical One: raw from the machine (bottom) and after four days of hand-finishing (top)

All of those bars have to be rounded to a uniform shape and then polished.

There are eight internal angles plus the angles between the round screw holes where they transition to the bars. Plus the polished countersinks around the screw holes.

All in all, around four days work . . . if all goes well.

That’s 11 full days just to hand-finish the four components illustrated here. There are more than 350 components making up the movement of Logical One, and while the majority of these do not take as long to hand-finish as those we have looked at here, every single component receives attention, no matter how small.

Imagine: all of that work and very few even knowing that such beautiful finishing exists. Fewer still fortunate in seeing it for themselves.

For more on high-level finishing, please see:

Does Hand Finishing Matter? A Collector’s View Of Movement Decoration

Video: Stephen Forsey On The Art Of High-End Finishing At Greubel Forsey

Behind The Lens: Philippe Dufour Duality

Why Philippe Dufour Matters. And It’s Not A Secret

And for more on the Romain Gauthier Logical One, please visit www.romaingauthier.com/logical-one.

Trackbacks & Pingbacks

-

[…] Decoration Why Philippe Dufour Matters. And It’s Not A Secret Objects Of Desire: Greubel Forsey Behind The Lens: Philippe Dufour Duality Why I Bought It: Greubel Forsey Invention Piece 1 Why Do Ul… * This article was first published on October 27, 2015 at Why We Are In A Golden Age For […]

-

[…] To get an idea of what superlative hand finishing looks like, I encourage you to check out the following articles: Does Hand Finishing Matter? A Collector’s View Of Movement Decoration Why Philippe Dufour Matters. And It’s Not A Secret Objects Of Desire: Greubel Forsey Behind The Lens: Philippe Dufour Duality Why I Bought It: Greubel Forsey Invention Piece 1 Why Do Ul… […]

-

[…] much boasts the best finishing you can find in a serial watch. Other contenders for this title like Romain Gauthier and Kari Voutilainen make about 10 percent (and less) of the number of watches that A. Lange & […]

-

[…] And let’s not forget that exquisite finishing! (See Why Do Ultra-High-End Watches Cost So Much? Hand-Finishing At Romain Gauthier Sheds Some Light.) […]

-

[…] Vallée de Joux features such as the use of “finger” bridges are more evident in Gauthier’s first watch, the HM, than in the more recent Logical One. But finishing approaches, including the use of beautifully beveled, sharp interior angles, are in evidence across the board (see Why Do Ultra-High-End Watches Cost So Much? Hand-Finishing At Romain Gauthier Sheds Some Light). […]

-

[…] Gauthier is an independent watchmaker of the highest order of quality and finishing (see Why Do Ultra-High-End Watches Cost So Much? Hand-Finishing At Romain Gauthier Sheds Some Light). His products rank among the most ingenious in terms of innovative mechanics, the most qualitative […]

-

[…] much boasts the best finishing you can find in a serial watch. Other contenders for this title like Romain Gauthier and Kari Voutilainen make about 10 percent (and less) of the number of watches that A. Lange & […]

Leave a Reply

Want to join the discussion?Feel free to contribute!

Just amazing, please send me some literature or catalogue. For these amazing pieces, I will be adding them to my extensive collection of timepieces soon. Thank you C.Carleen

12707 105th av ct e

Puyallup, WA 98374 USA

I just love this brand!

how much this watch ?

The Logical One in platinum retails for 139,000 Swiss francs.

Fantastic article, Ian! I’ve been extolling the virtues of his watches since he began and your article does a fantastic job of showing why. Well done!!