The year 2017 marks the tenth anniversary of the InnoVision, a wristwatch that was more than a timpiece: this special version of the Freak was more wrist-sized laboratory than anything else.

Ulysse Nardin InnoVision 2

The InnoVision heralded the future of modern watchmaking with ten different innovative elements; in particular it was the combined use of LIGA and DRIE technologies that represented a major breakthrough.

For details on the specific ten innovations of InnoVision 1 and full explanations of the LIGA and DRIE technologies, see Looking Back On 10 Years Of Ulysse Nardin’s Pioneering InnoVision Technology.

Ulysse Nardin InnoVision 2

Based on the research and development propelled by InnoVision’s technologies, the 2017 InnoVision 2 making its debut at SIHH is outfitted with yet another set of ten innovations.

And here they are.

1. Dual Constant escapement

Following on from the Dual Direct escapement portioning the energy from the gear train in the Freak and InnoVision, Ulysse Nardin’s Dual Constant is the next evolution escapement.

Ulysse Nardin InnoVision 2 Dual Constant Escapement

This patent-pending mechanism (actually, it has already earned two patents while a third is still pending) is a sophisticated constant force escapement comprising a silicon structure.

2. Direct silicon bonding

DRIE (deep reactive ion etching) is a plasma etching process that “etches” a silicon wafer tracing the outlines on a thin chromium mask, while simultaneously protecting the walls of the silicon micro components.

One of InnoVision 1’s innovations was a solid silicon escapement bridge as well as three-dimensional two-part mechanism created as one using DRIE. InnoVision 2 takes that a step further by using a bonding process to combine two silicon components.

The sealed bond is created by heating the parts at high temperatures (1,000-1,200°C) while adding oxygen, which creates a stable silicium oxide “joint.” This is a patent-pending element.

Ulysse Nardin InnoVision 2

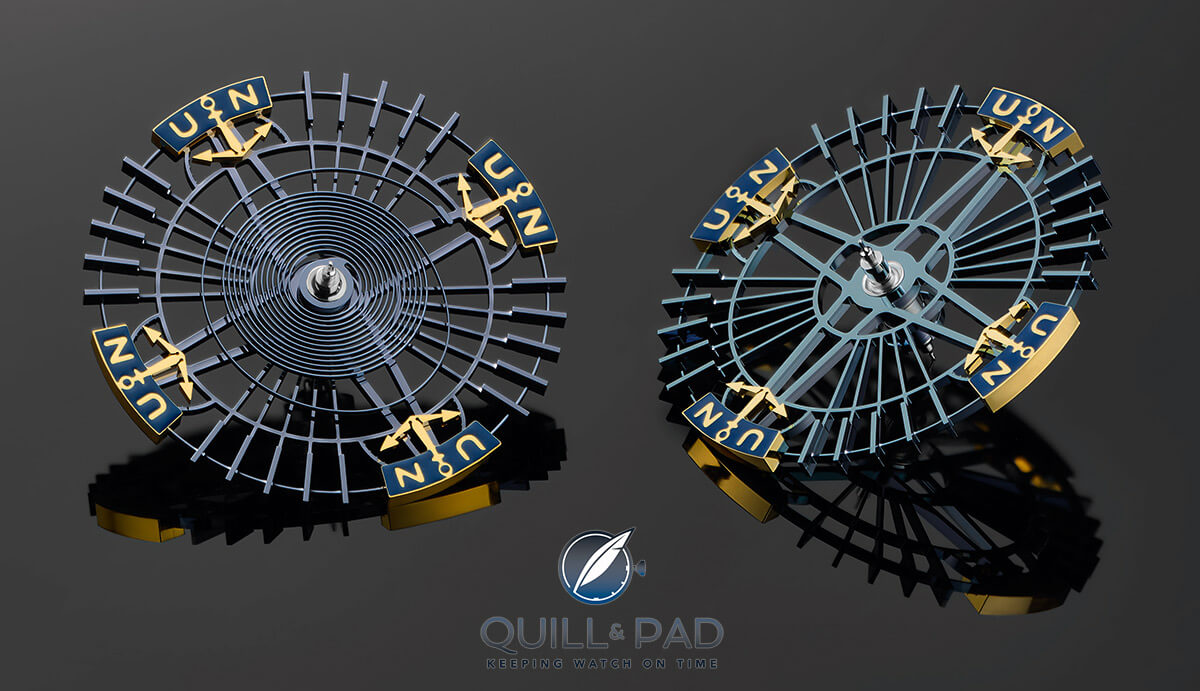

3. Silicon balance wheel with variable inertia gold mass

InnoVision 2’s balance is outfitted with a silicon balance wheel and spring, a combination that has been around for a while and has been adopted by a high number of manufacturers.

Ulysse Nardin InnoVision 2 silicon balance wheels

What’s really new here is the ability to make the balance with variable inertia by adding small gold masses for precision adjustment. This, too, is a patent-pending innovation.

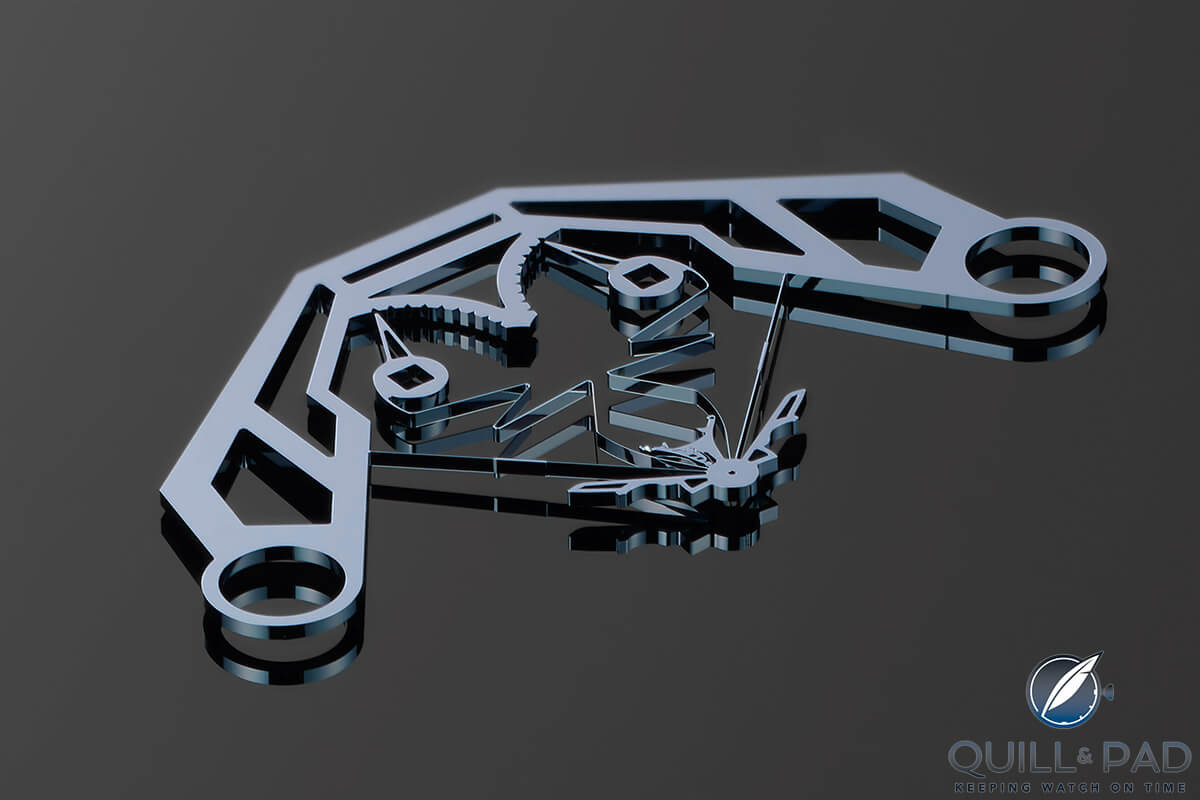

4. “Grinder” for automatic winding

Pioneered by Abraham Perrelet and Abraham-Louis Breguet, automatic winding has been around in very basic forms since 1770. The first genuine improvement arrived in the 1920s with John Harwood’s invention of a hermetically sealed case, and 1932 heralded the unidirectional winding rotor.

But just because usable, fairly efficient automatic winding exists doesn’t mean that engineers need to stop looking for better solutions. Which is why the InnoVision 2 contains a new automatic winding subassembly, starting with a centrally located ball-bearing rotor underneath which are three more small bearings operating upon two sets of filigreed-looking leaf springs. There is a ring attached to that with four spring ratchets, which engages with the winding wheel above the spring barrel. Adding a satellite reduction gear transforms the action into the ability to wind the mainspring.

The word “grinder” comes from sailing and it Ulysse Nardin evokes an image of a hard-working athlete with an important role in an efficient high-performance team. Ulysse Nardin’s engineers thought of the company’s high-profile association with America’s Cup contender Artemis Racing when naming this new configuration, whose raison d’être is improved efficiency and performance.

One patent has already been issued on this and one is still pending.

Back of the Ulysse Nardin InnoVision 2

5. Sapphire-coated silicon bridge

Together with Sigatec (a joint venture company between Mimotec and Ulysse Nardin created to harness much of the same ease in manufacturing already in use on LIGA micro parts and apply them to silicon) and the EPFL (École Polytechnique Fédérale de Lausanne), Ulysse Nardin has developed a patented method for coating silicon with a very thin one-micrometer film of sapphire (corundum).

This technology is used on the elongated center wheel bridge to provide harder surfaces and higher mechanical stability. A patent was issued for this.

Ulysse Nardin InnoVision 2

6. 24-karat hard gold wheels

Pure 24-karat gold is almost never used in watches as it’s far too soft and unstable, particularly inside the movement.

However 24-karat gold has been used in watch movement before. The first time in modern history, at least, was in the debut trio of H. Moser & Cie. watches (Mayu Caliber HMC321, Monard Caliber HMC342, and the Moser Perpetual 1 Caliber HMC341).

Using the x-ray LIGA process, Moser in conjunction with Forschungszentrum Karlsruhe’s Institute for Microstructure Technology realized a nanotechnical solution that allowed the reborn brand to manufacture a gold escape wheel and pallet lever as sleek and smooth as a mirror, with the additional benefit of making lubrication unnecessary.

Moser later searched out a different solution.

The InnoVision 2 now debuts gear wheels – which are generally made of brass – in 24-karat hardened gold manufactured using the same LIGA process.

Ulysse Nardin InnoVision 2

7. Glass bridge with integrated balance shock protection

Ulysse Nardin has been experimenting with glass, and the InnoVision 2 debuts the first results of this experimentation.

Ulysse Nardin InnoVision 2 glass bridge

What was a silicon balance wheel bridge with shock protection in the InnoVision 1 is now made of glass, a material with even less friction than silicon. And it has the added advantage of being transparent – which means it looks really cool.

And not to worry, it is not as fragile as one might think.

8. Channels filled with Super-LumiNova integrated into the glass balance bridge

Who doesn’t love visible mechanics that simply look cool?

Close up look dial side of the Ulysse Nardin InnoVision 2

This is another great reason to use glass: delicate channels can be carved out and filled with glow-in-the-dark Super-LumiNova for an amazing patent-pending visual.

9. New 24-hour time display

InnoVision 2 shows the precise hour, differentiating between 3:00 and 15:00 with ease by use of two rings underneath the dial printed with two sets of hours that switch around at the appropriate time.

There is a patent pending on this display.

10. Three-dimensional glass minute hand

The orbital wandering three-dimensional glass sculpture containing the gear train that points to the minutes in the middle of InnoVision2’s dial was made using precision laser cutting. And it is an absolute pleasure to look at.

There is nothing else like it on the market at this time.

Nor is there anything like InnoVision 2.

Ulysse Nardin Innovision 2

For more information, please visit www.ulysse-nardin.com.

Trackbacks & Pingbacks

-

[…] that the two watches that deserve the highest honors are the Greubel Forsey Grande Sonnerie and the Ulysse Nardin InnoVision 2. Both pieces are incredible horological […]

Leave a Reply

Want to join the discussion?Feel free to contribute!

This text sounds like you copied a press release directly into the article…

Well, if I showed you the press release I highly doubt you’d say that again. What I did was list off the interesting bits in this new watch. We’ll come back with a more in-depth article after the SIHH is over.

Thanks for clarifying, looked forward to your in depth thoughts on it and all the other innovations coming out…

Yes, all very good- but what time is it?

In the first photo it’s 10:00 pm. The glass bridge acts as a single hand, and the numerals show the full 24 hours.

What price this watch

It is a concept watch unique piece. It is not for sale.

Well knock me sideways…