You Are There: Visiting The Voutilainen & Cattin Case Factory And The Watch Case Museum In Le Noirmont

by GaryG

Ah, watch cases! As regular readers may recall, I have a particular fascination with the outer shells that encase, protect, and enhance the ticking mechanical wonders within (check out Why I’m All About That Case, That Case . . .). And if watch cases fascinate, why not visit a few case makers?

Let’s go!

A favorite case profile: case band view of the author’s Patek Philippe Reference 5370P

Interestingly enough, I haven’t found it that easy to gain access to case manufactures; for many brands case making is an outsourced activity, and others (Patek Philippe, for instance) prefer to keep this aspect of its operations mostly hidden from outsiders.

Our small group of California collectors did have a splendid visit a few years ago to Les Cadraniers de Genève, the dial and case manufacture co-owned by F.P. Journe and Vacheron Constantin.

The green glow: argon brazing of lugs to an F.P. Journe case at Les Cadraniers de Genève

Otherwise, however, it has been slow going – until this past January when friend and independent watch wizard Kari Voutilainen invited us to visit his case-making operation, Voutilainen & Cattin SA, with a side trip to the Watch Case Museum in the same town, Le Noirmont.

Making the case

After a pleasant two-hour drive eastward from Geneva to the small town of Le Noirmont and a delicious lunch in front of a roaring fire at a local inn, our group met up with Philippe Cattin, CEO of Voutilainen & Cattin SA.

Voutilainen & Cattin CEO Philippe Cattin explains the case-making operation

While Voutilainen has a major ownership interest in the business, pre-existing management is very much in evidence; for me one of the underappreciated aspects of Voutilainen’s success has been his ability to expand the scope of his operations and implement vertical integration, investing wisely in new assets and then putting the right management teams and processes in place.

As it turns out, Voutilainen & Cattin doesn’t just manufacture cases; it also conducts design studies, creates prototypes, and consults on technical challenges. Its specialty is the ability to go from start to finish on small-volume case production both for small independent customers and for limited editions made by large manufactures.

For smaller customers especially, it must seem a godsend to have a sympathetic supplier of these critical components specifically organized to deliver small, tailored volumes on a timely basis.

Ideal for small runs: compact and focused manufacturing layout at Voutilainen & Cattin

Of course, the Voutilainen cases and their components are much in evidence here: for instance, it was great fun to see a characteristic “Kari lug” in process.

How the magic is made: manufacturing and finishing jig holding a Voutilainen lug

One of my favorite parts of the visit was having the opportunity to meet the members of the team who worked on an exceptional project for two of my pals and I: the creation of display case backs for our Patek Philippe Reference 2526 Calatravas.

I had bought my Reference 2526 at auction in 2017 (see Why I Bought It: Patek Philippe Reference 2526 ‘Gobbi Milano’), and pals Michael and Allen, both also avid collectors of Voutilainen watches, already owned examples of this reference.

One of the greatest parts of the watch is the landmark Caliber 12-600 AT movement, Patek Philippe’s first automatic caliber and a lovely example of mid-twentieth-century design and finishing. The only bad news: all of that loveliness is concealed behind a solid case back!

Beauty revealed: Voutilainen & Cattin case back mounted on Patek Philippe Reference 2526

It was Allen’s idea to ask Voutilainen whether he might be able to make a display back, and when the answer was affirmative Michael and I quickly begged to join the effort.

I delivered the three watches to Kari in November, and by January the entire process of measurement, design, creation of brass prototype backs for each watch, final validation, manufacturing, finishing, and fitting of the gold backs had been completed.

The resulting work is splendid in every way, and if there’s a better example of the ability of Voutilainen & Cattin to turn around custom orders with excellence, I don’t know what it is.

The Voutilainen & Cattin custom case back reveals Patek Philippe Caliber 12-600 AT

A case-making museum?

I’ve been to many museums great and small over the years, and I’ll have to confess that my expectations for a museum about case making were pretty low, especially as we made our way past the children’s day-care center on the ground floor of the small museum building.

As it turns out I couldn’t have been more wrong and I heartily recommend that if you have any opportunity to do so, make the trip to Le Noirmont to visit and enjoy this little gem.

Watch Case Museum head Henri Cattin

I suppose that I shouldn’t have been surprised to find that our host for the visit was none other than Henri Cattin, Philippe’s father and long-time veteran of the case-making industry. Cattin explained to us that the museum was organized into two halves: one representing the pre-electric era in which machines were driven by foot pedals and hand-operated levers, and the second showing the gradual industrialization of the manufacturing process through motorization.

Old school: pre-electric-era workshop recreated at the Watch Case Museum, with a period painting of a similar workshop in the background

We started on the pre-electric side, going down the rows of benches and hearing about the functions of each of the specialized tools as well as seeing Cattin use the foot treadles to power several of the machines.

I’m a big fan of specialty tools used in different industries, and this museum has scads of them from a caliper that allows the measurement of the depth of a domed case back to crimping tools that make a uniform lip around the underside of an officer’s case back.

So that’s how they did that: specialized caliper to measure case back depth

Need to do some grinding? Get an aerobic workout at the same time with this leg-powered grinding wheel.

No need to go to the gym after work: manually driven grinding wheel

On the other side of this part of the museum were the heat-treating hood and open furnace for melting the metal to be poured onto molds and made into sheets; happily these don’t operate today as one can only imagine the heat – and soot –generated in the workshop.

Museum director Henri Cattin demonstrates the furnace

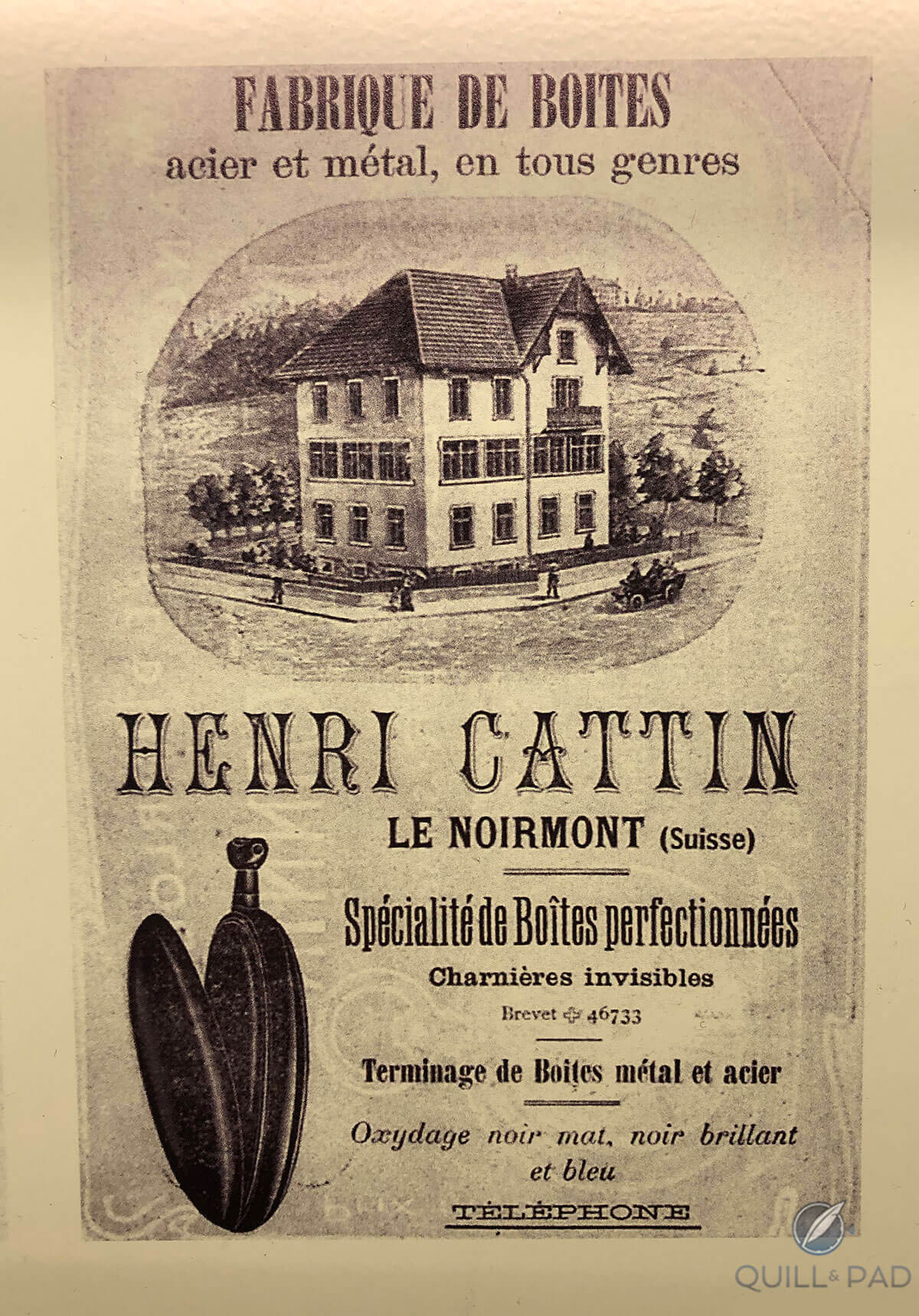

After a full demonstration, we moved over to the electrified side of the museum, on the way passing a reminder of the Cattin family’s longstanding involvement in this sector of the watch industry.

That name seems familiar: period advertisement at the Watch Case Museum, Le Noirmont

The mechanized portion of the museum held its own considerable interest as we followed a timeline beginning with machines dedicated to a single operation, followed by the evolution of machine development until it reached the point a single machine was capable of executing several sequential steps in the manufacturing process, saving time and labor as well as reducing the number of machines required to create an entire case.

As you might imagine, this put me in mind of the way that trajectory continued through to today’s highly flexible, software-configured CNC lathes and mills.

Electrically powered polishing and tumbling stations, Watch Case Museum

With mechanization also came routinization, as with the dies shown in the photo below that allowed complex forms to be stamped into semi-finished cases rather than engraved laboriously.

Pattern-stamping dies for case decoration

As we neared the end of our visit, Cattin fired up the overhead electric motors and the workshop came to life. While I’m quite sure that all of those whizzing belts and cables must have violated every known safety regulation, it was fantastic fun and all of us emerged unscathed!

If you have any interest at all in the history of fabrication in the watch industry, I’d strongly recommend that you make your way out to Le Noirmont and enjoy this museum. Should you do so, it will help a great deal if you or someone in your group can translate from French to English to make the most of Cattin’s descriptions.

And if there are other hidden treasures like this one that you’ve encountered in your travels, I’d love to hear about them in the comments section!

For more information on Voutilainen & Cattin SA, please visit www.voutilainen-cattin.ch.

Quick Facts Watch Case Museum, Le Noirmont

Address: Rue des Colverts 2, CH-2340 Le Noirmont

Telephone: +41-32-957 65 67

Email: [email protected]

Website: www.museedelaboitedemontre.ch

Cost: adults CHF 5, children under 12 free; private guided group visits (by reservation and in French) available for CHF 100

You may also enjoy:

Why I’m All About That Case, That Case . . .

Why I Bought It: Patek Philippe Reference 2526 ‘Gobbi Milano’

Here’s Why The Crown Is The Unsung Hero Of Watchmaking (And Why Rolex Wears The Crown)

Leave a Reply

Want to join the discussion?Feel free to contribute!

Can you share how much did it cost for the caseback? Did it still keep the watch water resistant?

Hi Sidd — thanks for your questions! Have agreed not to reveal the cost of the case back but I can say that I found it very reasonable. If anything, the new back is at least as watertight as the original!

Best, Gary

Hey Gary G. I’ve read a ton of your quill & pad articles and reviewed much of your IG photo collection. In your drool worthy photos, I notice you tend to identify a handful of daily wearers like your JLC Reverso GMT and VC Overseas Chrono. I have a JLC Grande Reverso Triple Calendar Moonphase and an RGM watch as my dailies. Inquiring minds want to know, what else are your favorite daily wearers? I’m always looking to add dailies with at least a date complication to my collection and look for pieces that fit into my lifestyle, where I ride my bike to work in San Francisco everyday. What are some of your other favorite daily wearers?