Precision and chronometry have been the holy grails of horology since its beginning. For thousands of years, watchmakers and scientists have striven to improve the accuracy of mechanical devices, from the first sundials and giant clocks in medieval churches to the marine chronometers crucial for navigation in the seventeenth and eighteenth centuries and wristwatches that once served as medical and scientific tools.

In the nineteenth, twentieth, and twenty-first centuries, expert institutions were founded to test and certify the quality of the wristwatch’s precision.

The most important and famous one today is Switzerland’s C.O.S.C. (Contrôle Officiel Suisse des Chronomètres), headquartered in La Chaux-de-Fonds.

Based on the ISO 3159 norm, this testing facility has certified billions of Swiss watch movements since its inception in 1973. Rolex is by far the institute’s biggest customer, submitting the largest numbers of mechanical movements for certification, followed by Omega, Breitling, TAG Heuer, and Panerai.

Interestingly, the millions of chronometer certificates issued each year account for only three percent of Switzerland’s annual watch production.

There is another chronometer-testing facility based in Glashütte, Germany. Initiated by German jeweler and watch manufacturer Wempe, here the entire encased watch (not only the movement as with the C.O.S.C.) is tested in the state-of-the-art laboratories installed the ancient Glashütte observatory. The tests are conducted in accordance with the DIN 8319 standard under the auspices of the state offices for weights and measurements of Thuringia (LMET) and Saxony (SLME).

Apart from the chronometer-testing institutes, there are a handful of other facilities including Chronofiable (which forms part of the Qualité Fleurier); its main job is to test the reliability of serially produced watches in strict and rigorous procedures such as shock and water resistance and forces exerted on components like the winding stem or pushers. In order to qualify for the Chronofiable test, the watch movement has to have first earned a C.O.S.C. certificate.

Omega De Ville Trésor in Sedna gold

Why, then, did Omega feel the need for a new certification?

With many quality seals and chronometry certificates in existence, one might think that in modern times there is no need for yet another testing method or hallmark.

While that may be true, some of today’s most prestigious watch brands still want to highlight the quality of their watches’ mechanical excellence and fine workmanship with their very own certificates; the Patek Philippe Seal, introduced in 2009, is a great example.

Although that brand’s highly sought-after timepieces have been stamped with the most elite and oldest quality hallmark in haute horlogerie, the Geneva Seal, which is exclusively for timepieces produced within the canton of Geneva, Patek Philippe apparently felt a need to differentiate itself by creating a new seal that goes even beyond those strict requirements.

One reason was that the Geneva Seal only applies to the movement’s finishing quality and does not include precision.

For Omega, a manufacturer drawing on a long tradition of precision timekeeping – even at the starting line of sports events – accuracy is tremendously important. The company’s name refers to its first watch movement created in 1894, the 19-ligne “Omega” caliber.

Famed for its accuracy and robustness, the Omega movement kicked off a success story that, at the turn of the century, included many observatory competition medals for accuracy. And in 1932 Omega earned itself the highest possible assignment for a watchmaker: that of becoming the official timekeeper of the Olympic Games.

Omega co-axial-escapement

In more recent times, Omega’s co-axial escapement, originally developed by the ingenious independent watchmaker George Daniels, was designed to again raise the bar for accuracy. This new technology, which minimizes friction and extends servicing periods, was the first new serially produced escapement in the last 250 years. It has now replaced the standard Swiss lever escapement in Omega’s movements.

The next step was the introduction of the non-ferrous Si-14 silicon balance spring in these movements. Thanks to the non-magnetic properties of the material, the performance of this crucial component, three times finer than a human hair, is unaffected by contact with magnetic fields.

The use of silicon in the balance is an immense accomplishment in terms of non-magnetic technology, an important field in modern horological research as magnetism is all around us in everyday life – from mobile phones to electronics and household appliances.

So Omega took this even further and developed a new standard in collaboration with Switzerland’s official authority for measurements, the Swiss Federal Institute of Metrology (METAS): the Master Chronometer certificate demands an extraordinarily high level of magnetic resistance of 15,000 Gauss plus an accuracy rate of less than 0/+5 seconds per day.

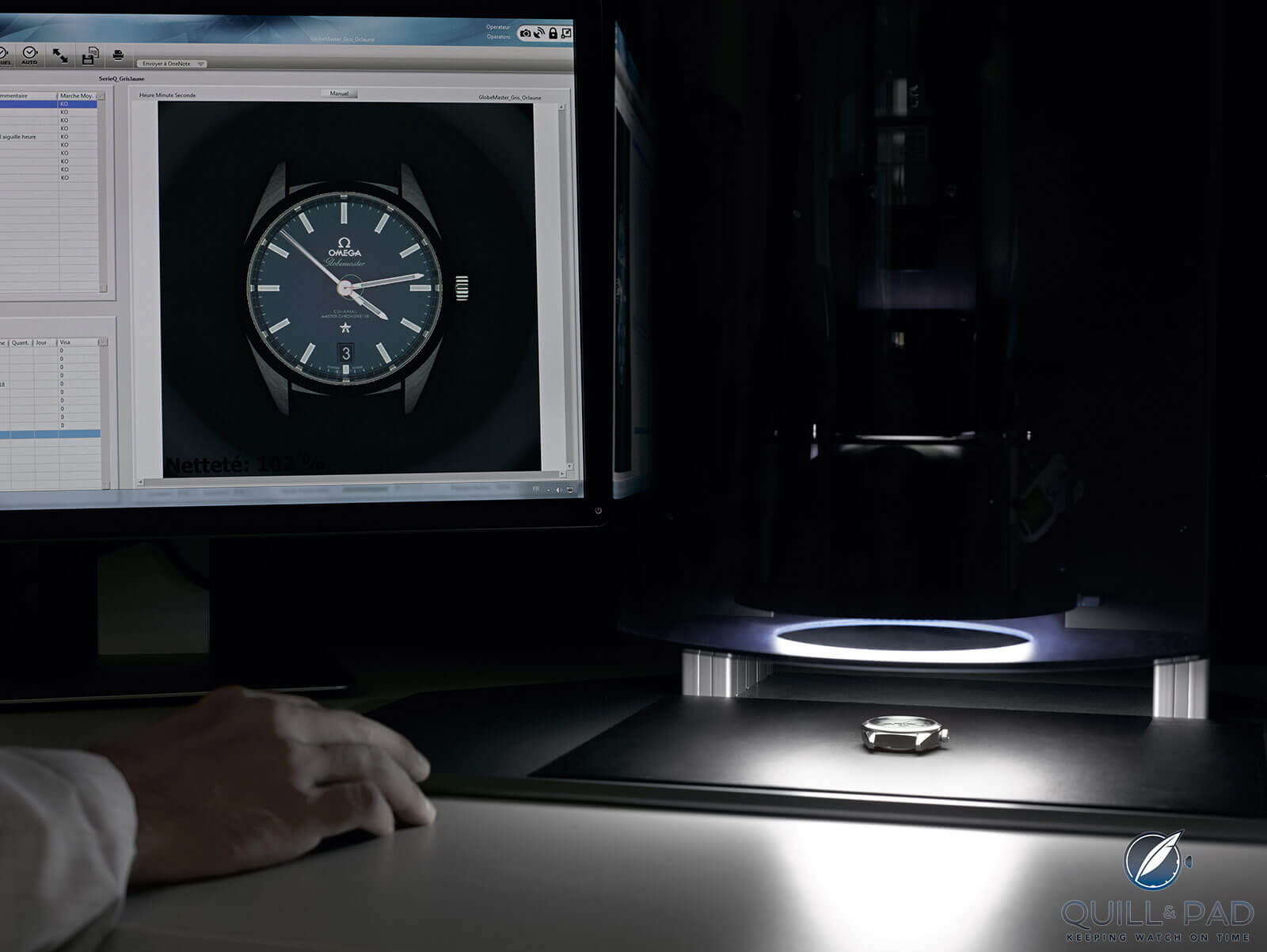

Extensive testing for 10 days: the step-by-steps of Omega’s METAS Master Chronometer certification

For a watch to earn the Master Chronometer certification, it first has to have earned a C.O.S.C. certificate. Then it will undergo eight tests executed over a period of ten days. These are carried out in Omega’s brand-new factory, which is part of the company’s headquarter complex in Biel.

Omega Master Chronometer certificate

The laboratories also house an office for METAS employees, who test samples and monitor the testing activities and processes.

The precise testing steps are as follows:

1. Testing function of the C.O.S.C.-certified movement during exposure to a magnetic field of 15,000 gauss.

This test examines the watch’s movement, placing it in two different positions and subjecting it to a magnetic field of 15,000 gauss. The proper functioning of the movement is audibly checked using a microphone.

2. Testing the functionality of the watch during the exposure to a magnetic field of 15,000 gauss.

This test is similar to the first one, but here the entire watch is subjected to a magnetic field of 15,000 gauss (and not just the movement). While exposed to this magnetic field, the functioning of the watch is also audibly checked using a microphone.

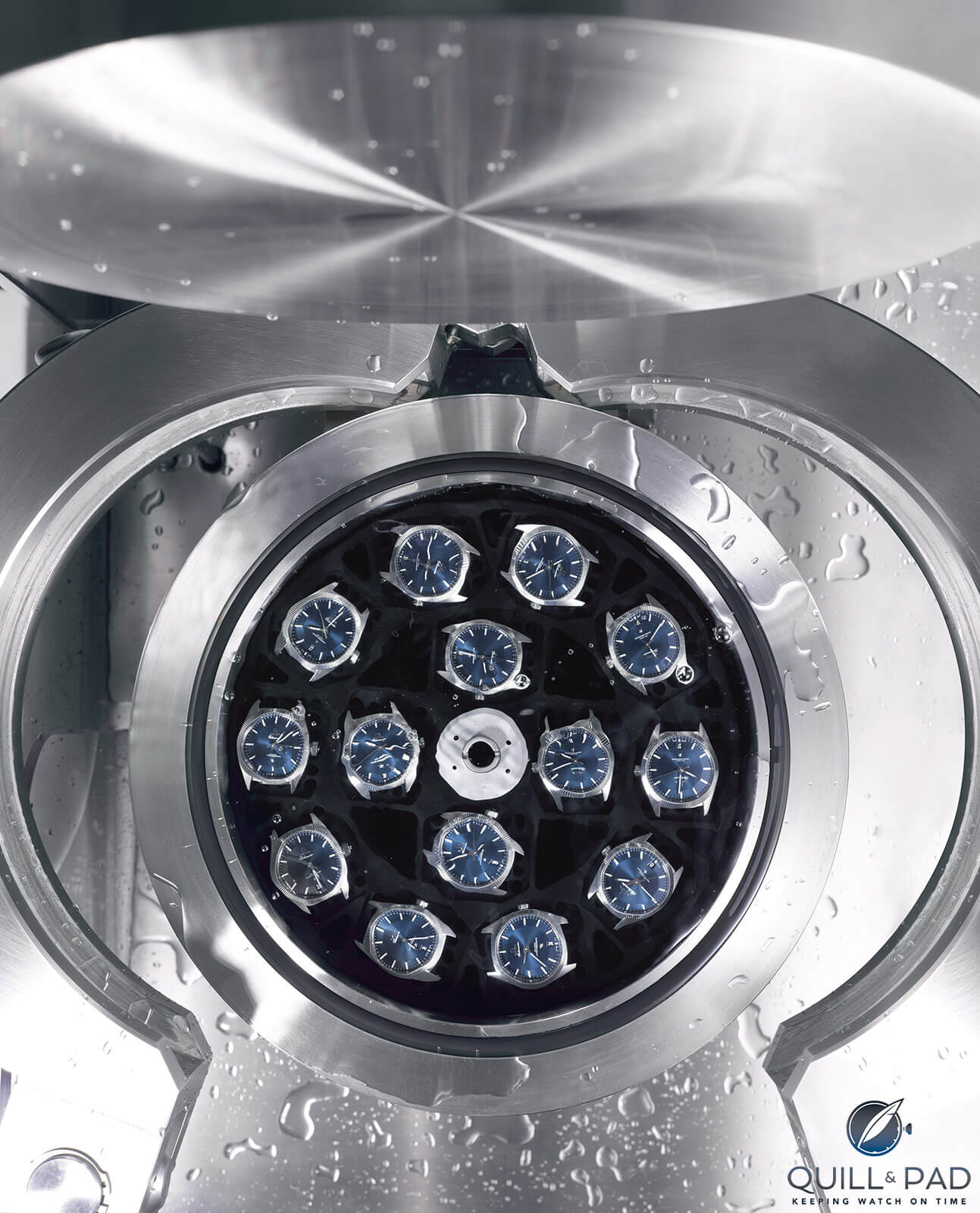

Omega watches being tested for METAS Master Chronometer certification

3. Deviation of daily chronometric precision after exposure to 15,000 gauss.

In this step, the watch is subjected to a magnetic field of 15,000 gauss; 24 hours later its chronometric precision is calculated. The next day the watch is demagnetized, and the rate is calculated after another 24-hour period. The deviation between the two days is recorded.

4. Average daily chronometric rate of the watch.

This test is carried out over four days. During this time, the watch is placed in six different positions and two alternating temperatures. It is again exposed to a magnetic field of 15,000 gauss. The chronometric precision is recorded each day. At the end of the four days, the results are used to calculate a daily average rate.

Omega watches being tested for METAS Master Chronometer certification: here specifically for water resistance

5. Power reserve.

This test checks the power reserve of the watch by proving that it continues to function at the limit of its expected capacity.

6. Deviation of chronometric precision in six positions.

In this test, the watch is placed in six different positions and its rate is recorded in each one. Out of these six results, the deviation between the two most extreme results (known as the delta) is shown.

7. Deviation of rate between power reserves of 100 percent and 33 percent.

Here, the watch is placed in six different positions and its rate is recorded at 100 percent power reserve in each one. This process is repeated when the power reserve of the watch reaches 33 percent. Omega then takes the average results of the six measures during both states of the power reserve and provides the rate deviation between the two.

8. Water resistance.

This test submerges the watch, gradually applying more pressure to the point of the stated water resistance to a maximum of 150 bar.

Testing Omega watches for METAS Master Chronometer certification

Double certification and sharing results

In conclusion, the predicate “Master Chronometer” on the dial means that the watch not only has earned two certificates – the METAS and the C.O.S.C. certificates – but also ensures a completely transparent testing process.

Customers can view the results of the intense tests their watches have completed online by entering the certificate number on the red Master Chronometer Certificate card that comes with the purchase of the watch.

Gold and gray at its best: Omega De Ville Trésor 40 mm in Sedna gold

One of the most recently released Master Chronometers presented in 2019 is a new lineup of the De Ville Trésor 40 mm, the brand’s beautiful manually wound and notably thin dress watch, which first made its debut in 1949.

Omega De Ville Trésor Sedna Gold

What can I say? Over the course of 70 years, this timepiece’s charm has remained unchanged by time; it is a picture-perfect example of successful vintage design in the best sense of the word timeless.

Three variants were introduced in 2019, one nicer than the other, and I instantly fell for the version that pairs Omega’s Sedna gold case with a gray dial – although I would not mind wearing the steel model with a patterned blue dial, either.

In 2019, the collection welcomes its first oven-fired enamel dials that allow for particularly expressive and long-lasting color. And by long-lasting I mean centuries.

Omega De Ville Trésor in Sedna gold

I have always had a penchant for dark gray dials, and the color choice is impeccable against the warm hue of Omega’s Sedna gold case. The Sedna gold polished hands and domed indexes elegantly contrast against the dark backdrop.

While the design represents yesteryear’s style in the best way possible, the De Ville Trésor 40 mm boasts a top-notch modern movement: Master Chronometer co-axial Caliber 8928 with manual winding offering a healthy 72-hour power reserve.

View through the Omega De Ville Trésor’s display back to Caliber 8929

The De Ville Trésor 40 mm also boasts excellent finishing – one example being the Sedna gold balance bridge with radial guilloche decoration that directs the eye right into the heart of the watch.

For more information, please visit www.omegawatches.com/planet-omega/watchmaking/the-master-chronometer-certification.

Quick Facts Omega De Ville Trésor Sedna Gold

Case: 40 x 11.6 mm, Sedna gold

Movement: manual winding manufacture Caliber 8929, 4 Hz/28,800 vph frequency, power reserve 72 hours, certified Master Chronometer, free-sprung balance with silicon balance spring, twin serially operating spring barrels, resistant to magnetic fields up to 15,000 Gauss

Functions: hours, minutes, seconds

Price: $15,000/€14,000

You may also enjoy:

New 2019 Omega Seamasters: Confessions Of A Secret Seamaster Fan

What Is Qualité Fleurier? The Rare Certification Explained

Point Of Reference: The Standards Of The Geneva Seal

The Truth About Magnetism And Watches

Decoding Omega References: 14 Magic Digits And Codification Tables Revealed

Trackbacks & Pingbacks

-

[…] The edition is limited to 7,007 pieces – each watch’s individual number is shown on an 18-karat yellow gold plate on the case side – and Omega as usual plays with the 007 theme elsewhere as well. The same yellow gold was used to craft the hands and indexes, including the one at 12 o’clock, which is an inspired replica of the fictional Bond family’s coat of arms. On the seventh day of the month, the date window’s “7” shows up in the 007 logo font. And there is a hidden “50” in the Super-LumiNova of the marker at 10 o’clock, which only shows up in low-light conditions when the luminous substance goes to work. The automatic movement inside this timepiece is a certified Master Chronometer. […]

Leave a Reply

Want to join the discussion?Feel free to contribute!

Hi Sabine, enjoyed the article very much, but noticed a small error: you mention that the “millions” of chronometer certificates issued annually represent only 3% out of the totality of watch sales. The most recent figures I’ve seen have annual production pegged at approx. 7.5MM units for 2018, so 3% would be roughly 225,000 chronometers.

Hi Korin,

Thanks so much for your interest in our feature. You were right: C.O.S.C. says about 6 and not three percent of the exported Swiss watches have earned their title. The annual volume is about 1.8 million chronometers. For more information, please go to https://www.cosc.swiss/en/cosc/key-figures. We will update the figures.

I’m sure Mido are or were 4th in the COSC stakes. I might be wrong of course. For myself, the Patek Philippe Seal carries as much weight as “This is a genuine pair of Levi’s”.

The new De Ville is very classy, but I’m yet to be convinced on the advantages of the co-axial escapement. I would also sincerely like to know whether a simple soft iron cage does the job as well as all these expensive solutions to magnetic fields.