My hands are crucial to personal creativity. Working in product development, I regularly have to use my cleverness and ingenuity to solve problems. However, if I am unable to apply my solutions in a practical, hands-on way then an innovative idea may often remain simply that: an idea. I need to use my hands and practiced skills to manipulate tools, materials, and techniques to bring ideas into the real world.

The ability to use all ten of my digits nimbly and precisely to take raw materials or components and create a functional object is how I have defined most of my adult life. While I write about technical ideas, and design and engineer new things in CAD, it is in applying my hands to the task of creation that makes me feel that I add value to the world.

My relationship with my hands and their ability to create has led to one of my biggest fears being the loss of my hands in a tragic accident.

Being able to use my hands to shape, manufacture, assemble, and manipulate a variety of objects or mechanisms is the result of three decades of repeated practice. From my first Lego and Erector sets before entering pre-school all the way to hand-fabricating watch components, I have spent a lot of time practicing the application of my hands to creation.

The result is a firm understanding of just how much effort goes into creating things entirely by hand.

In my adult life I have had the luxury of high-quality machinery, CNC-capable manufacturing, and automated processes to expedite the realization of my ideas, yet when I put ample manual effort into creating an object it feels more realized than if I outsource the creation to an automatic machine process.

This is why when we discuss watchmaking and the development of a fully handmade watch, I will not try to undersell how incredible it is. I have personally spent days and weeks working on simple non-mechanical watch components only to look at what some of the best watchmakers are doing and still stand in awe.

That is probably why the independents typically are my favorites: on average they tend to employ more hand skills per watch than the quasi mass-produced big-brand watches.

In the past I have covered many individual watchmakers and indie watch brands that focus extensively on hand skills, specifically the Naissance d’une Montre, Le Garde Temps, a collaboration between Robert Greubel, Stephen Forsey, and Philippe Dufour to teach every traditional watchmaking skill possible to master watchmaker Michel Boulanger.

The entire purpose of the project was to focus on hand skills alongside preserving traditional knowledge, and for that reason it comes as no surprise that Greubel Forsey has decided to release a (virtually) completely handmade timepiece under its marquee.

Greubel Forsey Hand Made 1: note the ‘hand made’ in place of ‘Swiss made’

Aptly named Hand Made 1, I see it as the inevitable continuation of a desire to highlight incredible watchmaking done by hand matched with the superlative finishing that Greubel Forsey is famous for. Let’s dig in.

Greubel Forsey Hand Made 1

Hand Made 1 is literally what it sounds like: a completely handmade watch to Greubel Forsey’s standards.

Greubel Forsey Hand Made 1

Okay, just to get it out of the way, it isn’t 100 percent handmade because Greubel Forsey doesn’t make the jewels, sapphire crystal, case gaskets, mainspring, spring bars, and strap. But that’s it.

Not many brands can even claim to make all the remaining components themselves, let alone make them all by hand. Stephen Forsey estimates that the watch is at least 95 percent handmade depending on how you calculate the ratio. This means that all wheels, pinions, plates, pivots, screws, dials, hands, balance, and even the balance spring are all made by hand and then assembled by one single watchmaker.

Assembling the Greubel Forsey Hand Made 1

A main criterion of Hand Made 1 was to be built from start to finish by one individual watchmaker. While it isn’t clear how many people are involved in the production of all of the components, a single watchmaker takes all the individual components and builds and regulates the watch to completion.

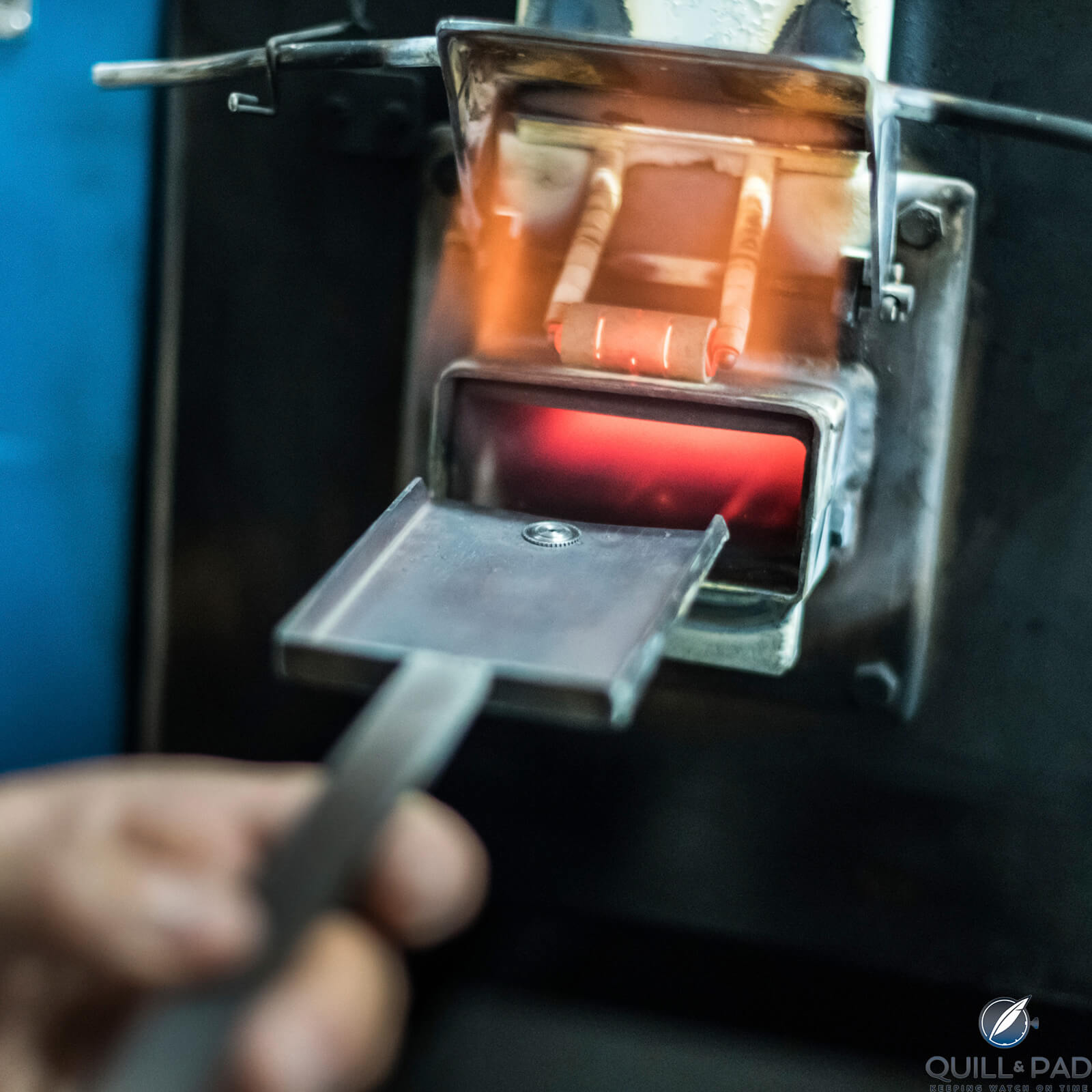

Making components for the Greubel Forsey Hand Made 1

A talented watchmaker makes every part of the movement by hand and completes all the hand finishing and crafts the case – all on fully manual machines with no computer assistance.

Making components for the Greubel Forsey Hand Made 1

The one concession allowed is that the machines can have an electric motor to spin the tool or component; in other words, largely traditional lathes, mills, or drills are fair game.

But this means that, in the best-case scenario, the watchmakers will be more or less using technology from a century ago combined with their own two hands to create a precision watch to the standards of the brand most widely known for its attempts at utter perfection.

Gratté finish on the movement of the Greubel Forsey Hand Made 1

This can be seen most obviously in the finishing, which requires up to four and half months and is considered one of the best in the world. But it’s the part fabrication that should impress the most here.

Patience goes a long way

As we learned with Le Garde Temps, fabricating precision micro components by hand not only takes the skill and knowledge of the techniques involved, but also the patience to consistently perform said techniques. Michel Boulanger liked to discuss how a foul mood, being hungry, or simply being in a hurry could cause a tiny tolerance to be missed that would require starting over.

This would also ring true for these components, something evident in the fact that to successfully make all of the approximately 300 parts can require making more than double that number to get each one in consistently high quality. What can help is keeping the parts simple, and the Hand Made 1 takes that message as far as is possible for a one-minute tourbillon movement.

Greubel Forsey Hand Made 1 on the wrist

The aesthetic is along the lines of typical Greubel Forsey, which one might call vintage architectural. The bridges and cocks are very simple, and the height is kept to a minimum (aside from the tourbillon support cock). While the shapes themselves are rather basic, not everything is simple because then it wouldn’t be a Greubel Forsey.

The wheels are all crossed out with five spokes and 40 sharp internal angles (all hand filed); the cocks for both the tourbillon and the seconds subdial as well as the tourbillon cage have perfectly polished barrel sections. And every flat surface that isn’t black polished is simply exquisitely finished.

Greubel Forsey Hand Made 1

Whether it’s a blasted, satin-brushed, snailed, or blued finish, no surface is anything other than perfectly hand finished, just like a Greubel Forsey should be. The rear of the movement has an unusual “gratté” finish, which means “scratched” in French. And the look isn’t far from it.

It reminds me of the hand-scraped surfaces commonly found on vintage machines, especially those that have been rebuilt. Hand-scraped ways, columns, and other flat reference surfaces are a great example of another historical (and endangered) skill that takes true craftsmanship and patience to perform at the highest level. That statement is pretty much the thesis statement for the Hand Made 1 – and Greubel Forsey as a company.

Greubel Forsey Hand Made 1 from the side

Everything Greubel Forsey does is about nurturing incredible skill, craftsmanship, and a fundamental belief in patience. That is the only way that a Greubel Forsey watch can exist, and this rings doubly true for the Hand Made 1. Like every watch from the brand it looks absolutely perfect from every angle, and the experience is magnified when you realize that not only is this watch completely hand finished (the norm for Greubel Forsey) but wrought from scratch by an individual’s hands.

Given the time investment to make one piece (supposedly around 6,000 hours), it is no surprise that the planned output is two to three pieces per year maximum. But output isn’t important, the effort and skill required to accomplish such a feat is everything that matters.

With a watch like this, practicality goes out the window. One might say the same for any Greubel Forsey, but the Hand Made 1 sets the upper level of what is possible for one of the highest quality watch brands in existence.

It all comes down to two hands – or more likely, many, many sets of two hands.

Greubel Forsey Hand Made 1

The fact of the matter is the Hand Made 1 is largely unprecedented for a brand of any size but if things go well, this won’t be the last entirely handmade watch by Greubel Forsey because it wants to take the idea and run with it.

I for one welcome a focus on the heritage of fabrication instead of solely on exclusivity or luxury. As someone who makes things every day with my own two hands, I would agree that it is crucial to preserve at every chance you get.

Let’s (carefully) break it down!

- Wowza Factor * 9.1 Everything Greubel Forsey does is incredible, but a “production” watch that is truly handmade? Brilliant!

- Late Night Lust Appeal * 91» 892.405m/s2 When things hit so close to home it can lead to many a sleepless night!

- M.G.R. * 62.9 The movement is simple, yet the implementation is so difficult it surprises everyone!

- Added-Functionitis * N/A Of course it is time only. It feels like it’s always time only! I guess we can skip the Gotta-HAVE-That cream again!

- Ouch Outline * 12.1 Waking up to a pounding head and a back that won’t budge! Getting older, man, it’s not an easy task. Still, you’d hear no complaints from me if I happened to have the Hand Made 1 on my wrist!

- Mermaid Moment * It’s made by what now?! The connection is instant and permanent, too bad it is also prohibitively positioned above my dreams.

- Awesome Total * 808 Take the number of hours in the power reserve (60) and multiply by the gold purity of the case (18k), then subtract the number of components in the movement (272) for an awesome total made entirely by hand!

For more information, please visit www.greubelforsey.com/en/collection/hand-made-1.

Quick Facts Greubel Forsey Hand Made 1

Case: 43.5 x 13.5 mm, white gold

Movement: manual winding Caliber Hand Made 1 with one-minute tourbillon, 3 Hz/21,600 vph frequency, 95% made by hand

Functions: hours, minutes, seconds

Limitation: 2-3 per year

Price: 1 million Swiss francs

You may also enjoy:

A Hero’s Journey Begins And Ends: Naissance d’Une Montre, Le Garde Temps

Philippe Dufour Explains The Goals Of Time Aeon And Oscillon (Video)

Le Garde Temps Project With Greubel Forsey And Philippe Dufour: Where It’s At And Where To Next

Leave a Reply

Want to join the discussion?Feel free to contribute!

As a man who fabricates metal jewelry by hand. I stand or at my age sit in awe of the hand work done at a microscopic level on this watch. Amazing and really almost incomprehensible to me. Kudos and thank you for this type of article.

Thanks for the write up. I’ve been wanting to read a detailed review of watch.

What I’m curious about is how GF get the levels of fabrication within the tight tolerances necessary. Watchmakers have been using CNC processes in order to get measurements as precise as possible. If GF doesn’t do this, wouldn’t there be a limit on just how precise (and therefore how accurate) this watch can be?

This is separate from an appreciation of just how much work goes into it, but it’s something that I really want to know: just how does GF ensure the levels of precision necessary?