by Bhanu Chopra

In 1999, with Germany’s reunification now ten years in the past, Dirk Dornblüth, a master watchmaker, gave his father for his sixtieth birthday a watch he had designed himself based on the Glashütte Caliber 60.3 – prompting his father to revive a 40-year-old dream.

Thus, D.Dornblüth & Sohn’s watchmaking workshop was established in 1999 by Dieter Dornblüth and his son. In 2002 the atelier released Model 99.2, its first watch based on a design Dieter had originally sketched out in 1959, which was inspired by a customer’s difficult-to-repair pocket watch to which he had grown quite attached.

The small brand is now known for fine German watchmaking in the traditional handmade manner. But as I found out, there is so much more to this independent maker.

The D.Dornblüth & Sohn handmade red ceramic dial

Visiting D.Dornblüth & Sohn

It was a late September day when a WIS buddy and I drove from Berlin to Kalbe to visit D.Dornblüth & Sohn, which took us 2.5 hours in Friday morning traffic. For the last 70 kilometers, we felt disconnected from rest of the world, induced in great part by a lack of cellular reception, as we drove through the farm country and picturesque landscape of Sachsen-Anhalt.

Kalbe is in no way comparable to the German centers of watchmaking Glashütte or Pforzheim. On the contrary, this is a small, secluded village with a sparse population. While Sachsen-Anhalt is the fourth largest German state in terms of area, it only comes in tenth (of 16 states) in terms of number of inhabitants. Its northern region is particularly thinly populated; Kalbe has about 7,500 registered inhabitants.

Unlike Glashütte and Pforzheim, there are no impressive factory buildings here – or, for that matter, even a restaurant in the village, even if the ruins of a ninth-century castle remain visible.

D.Dornblüth & Sohn workshop in Kalbe, Germany

Dirk Dornblüth now runs the workshop housed in a modest two-story house with a pointed gable over the entrance; apple and plum trees and a small creek passing through the property complete an utterly idyllic feel.

The front of the house features a large Dornblüth clock, which appears to be modern yet traditionally styled. Maintained by Dirk, it is powered by an old tower clock mechanism. Dirk Dornblüth not only makes watches, he restores vintage and modern watches and clocks. His watchmakers have all learned to make machinery and watch parts required for restoration work.

Dirk Dornblüth at his watchmaker bench

As we begin our tour of the workshop, I realized that craftsmanship in Kalbe has a very different sense than what I normally witness in Glashütte workshops. Manufacturing a watch at D.Dornblüth & Sohn with only nine employees diverges from manufacturing in German watch centers, where parts are made in separate divisions with five to ten, or even more, employees per division.

There is a dining table in middle of the Dornblüth workshop where the employees gather with Dirk every morning to discuss everyone’s responsibilities for that day. Daily breakfast meetings in the D.Dornblüth workshop are the key to its success.

The ground and first floors of the building are filled with vintage machines used to create tools and other machines for watch parts like dials, hands, plates, gear trains, and apply engravings. Most of these machines and parts are no longer available, therefore they are painstakingly rebuilt.

The workshop appears to me as if it had come straight from the nineteenth century with its vintage, manually operated machines, some even dating as far back as 100 years. There is not a single CNC machine in sight. The most modern object we saw was an early 2000s desktop computer used for construction purposes.

A Dornblüth movement ready to be assembled

Dirk Dornblüth informed us that this workshop manufactures approximately 80 percent of the parts needed to manufacture a Dornblüth watch, which is very impressive.

The watchmakers make all the dials, hands, and almost all of the movement parts (depending on the caliber) in this workshop, though the jewels and springs are not made in Kalbe. The Dornblüth cases are made by a metal-working company that has now become a supplier to the watchmaking industry.

It is no secret that movements of the 99 series are based on an Unitas caliber. However, these base movements are modified and completely reworked in Kalbe. With the Quintus-2010 collection, Dornblüth offers movements with 95 percent of the parts manufactured in-house.

A beautiful Dornblüth movement

The swan-neck springs, for example, are milled from a round steel plate with the help of a pantograph to define the perfect curved shape. The winding wheels are milled, cut, and drilled from a blank on old machines.

All the steel parts are hardened by heating in the furnace at high temperature, then rapidly cooled down in an oil bath. The steel is heated and cooled down a second time very slowly. This second stage dissipates the high stresses created in the steel during hardening.

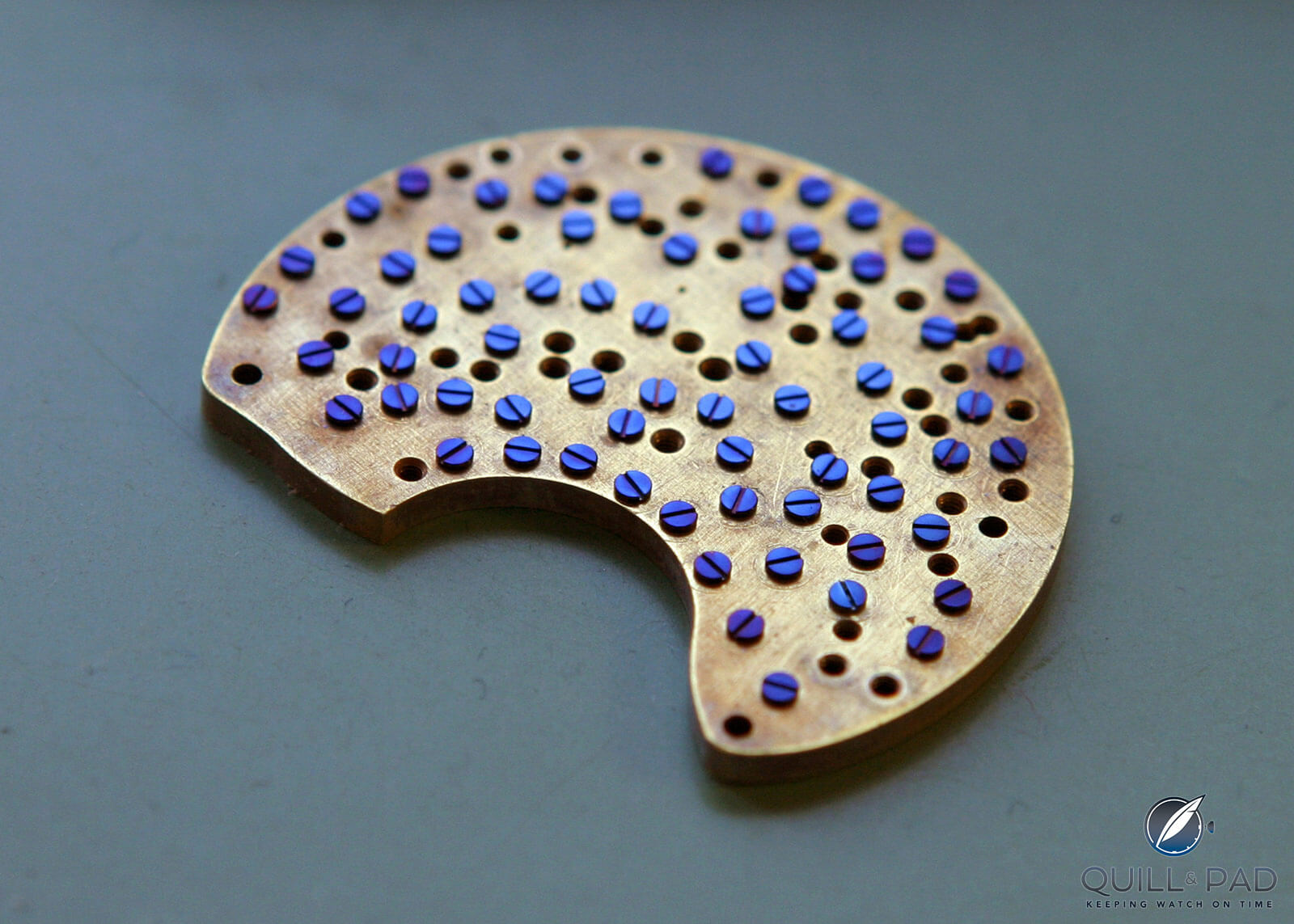

Bluing screws at Dornblüth

This second step is the same process by which the blued parts – screws and hands – obtain their color.

We then move to the first floor, where the space is compact and cozy.

This is where the dials are made and the hands are finished, polished, and thermally blued. In a different room, technicians also polish cases, assemble watches, and perform repairs and revisions.

We noticed a few vintage and high-end modern watches being repaired. Prestigious brands and collectors send their vintage watches to Dornblüth to fix when they are unable to source a part. Dornblüth and his team can make components, which sometimes necessitates making a tool to build a specific part.

Dornblüth dials

Dornblüth uses slender, classically shaped hands. Before the hands are treated, they are hand-polished, which is a difficult and time-consuming task since they are made of hardened steel.

When the hands reflect evenly across their entire surface, and the edges are nicely rounded, they are ready for tempering.

Without using varnish or other coloring agents, the hands get their characteristic shade of cornflower blue over a flame by heating slowly. Heating oxidizes the steel to different shades of color, ranging from yellow to red and violet. Dornblüth’s blue is reached at exactly 300°C.

Blued hands at Dornblüth

As we toured the dial-making room, I examined the various dials made by Dornblüth. I became captivated by a black one with a matte texture and white numerals with applied lume.

Ute, the technician responsible for dial manufacturing, explained that this was a ceramic dial with applied lume that is offered as an option on all models in 2020.

I knew that Dornblüth’s team had made brown ceramic dials in limited quantities in the past, but I was so taken by the black dial that I immediately took off my own 99.1 watch and asked if it was possible to replace my silver dial with the new ceramic dial.

Happily, my request was enthusiastically accepted, and I received my re-dialed watch couple of months later.

Manufacturing ceramic dials at D.Dornblüth & Sohn

Watch dials are usually printed using a tampon or stamping process known as pad printing, whereby the dial’s markings are “printed” by a hand-driven machine resulting in a flat finish.

In contrast, Dornblüth makes engraved dials that are hand-milled with a special cutting machine to create deeper, more defined impressions before being hand-finished and painted.

A Dornblüth-engraved and lume-filled ceramic dial

Sections on a watch dial are carefully hollowed out with a handheld milling machine. Once this process is quality controlled for precision, color or luminescent pigment is meticulously hand-applied to the milled areas by one of the watchmakers. The result is a sharp and clear finish with practically flawless edges.

Ceramic dials are high-tech products that very much resemble classic enamel dials in appearance, minus the brittleness of the enamel.

Dornblüth buys the raw brass material and stamps out the blank in house. Then Ute attaches a “filling ring” to it before adding the mixture consisting of ceramic, resin, and the desired color. The material hardens in a specially developed curing process comprising several steps.

Once set – meaning when the ceramic is solid – the dial is polished by hand and engraved using a hand-driven pantograph so the resulting milled recesses can be filled with color before the desired matte or glossy surface finish is applied.

The ceramic dials are engraved traditionally without computerized machinery using a pantograph. The hand-driven pantograph utilizes a system of rigid, jointed bars to trace and reduce a hand-drawn template, which is 800 percent bigger than the desired dial, complete with details such as numerals, baton markers, and inscriptions.

The result is a handcrafted, exact miniature of the template, consistent in detail and perfectly re-sized for a wristwatch.

Dornblüth stresses that the high-strength surface structure of this dial exceeds enamel in terms of elasticity and resistance to shattering. And Dornblüth can produce ceramic dials in almost any color while guaranteeing color stability.

The author’s Dornblüth 99.1 with its original silver dial and blued steel hands

My Dornblüth 99.1 retro-fitted with a ceramic dial

I am very pleased with how my new ceramic dial turned out.

I still appreciate the classic silver dial my watch originally had in combination with the blue numerals and hands, but the new black ceramic dial is just striking and easy to read in low-light conditions with its bright lume.

The author’s Dornblüth 99.1 with its new black ceramic dial and polished steel hands on the bench

The two dials are like yin and yang, complete opposites of each other, yet perfectly harmonious.

Even though Dornblüth offers some standardized watch models in its catalog, what really stands out is this maker’s ability to customize watches thanks to the high degree of work done in house.

A Dornblüth model with a fresh variation: a translucent green dial

Dornblüth and his team can customize a wide variety of colors and materials, including a new green translucent dial as seen above.

As we wrapped up the tour and began our drive back to Berlin, I couldn’t help but think about how that visit to Kalbe gave me a completely new perspective on what it takes to make Dornblüth watches.

Transformation complete: the author’s Dornblüth 99.1 with black ceramic dial and polished steel hands

A Dornblüth watch is truly unique due to painstaking labor with traditional machining methods that is ever increasingly rare today.

For more information, please visit www.dornblueth.com.

Quick Facts Dornblüth 99.1

Functions: hours, minutes, small seconds

Case: 42 x 11.5 mm, stainless steel, domed sapphire crystal 1.6 mm

Movement: manually wound Caliber 99.1 (Unitas base), 50-hour power reserve, 2.5 Hz/18,000 vph frequency, red gold-plated three-quarter plate, 4 chatons, swan-neck fine regulation

Price: $4,160

* This article was first published on July 25, 2020 at Why I Upgraded My D.Dornblüth & Sohn 99.1 Watch With A Handmade Ceramic Dial.

You may also enjoy:

In Praise Of Habring2: A Collector’s View

The Gorilla Fastback Collection: Extended Review & Something New

Design Your Own Watch? A Collector Explains The Pros And Cons With Ochs Und Junior

Leave a Reply

Want to join the discussion?Feel free to contribute!

Yummy!

And a great price. 😊

Beautiful watches at surprisingly competitive prices considering the small size of the company’s operations. An interesting company to read about, they show a true dedication to the art of watch making!