New Release: Naissance d’une Montre 3 by Ferdinand Berthoud, a Top Contender for The World’s Best Watch

by Ian Skellern

“Au Temps Qui Instruit” [Dedicated to time, the great teacher]

It’s easy to come up with superlatives for any watch by Ferdinand Berthoud, but Naissance d’une Montre 3 (NDM3), but none would even come close to doing this timepiece justice. I’ve no idea how much it costs (the first watch will be auctioned), just as I’ve no idea what Michelangelo’s Statue of David might cost, and I really don’t care. As far as I’m concerned, NDM3 is, at time of writing, the most desirable watch on the planet.

Naissance d’une Montre 3 by Chronométrie Ferdinand Berthoud

From the press release

Naissance d’une Montre 3 is a horological heritage project with an important human dimension representing the culmination of six years’ work. The result is a timekeeper conceived for the wrist, officially chronometer-certified by the COSC and handcrafted using traditional tools, without digital assistance.

Constant force via a fusee-and-chain transmission system, bimetallic balance, central seconds hand, open structure: its technical and aesthetic characteristics are deeply rooted in the heritage of the Master Watchmaker, Ferdinand Berthoud.

As expected, the 11 “Naissance d’une Montre 3” chronometers meet the same quality and finishing criteria as any other contemporary timepieces from Chronométrie Ferdinand Berthoud. They offer vivid proof that what truly counts is the journey rather than the destination – and that this journey is shaped by the passing of time, the “temps qui instruit” [Dedicated to time, the great teacher] in the words of Louis Berthoud, Ferdinand Berthoud’s nephew.

Coinciding with the tenth anniversary of Chronométrie Ferdinand Berthoud, the presentation of Naissance d’une Montre 3 is the outcome of an ambitious dream nurtured by its founder and President Karl-Friedrich Scheufele.

This outstanding cross-disciplinary project drew on the expertise of more than 80 artisans and specialists from Chronométrie Ferdinand Berthoud and Chopard to create a contemporary watch, entirely handcrafted and inspired by Ferdinand Berthoud’s Astronomical Pocket Watch No. 3.

The result is a series of 11 contemporary timepieces, powered by a unique combination of a split bimetallic temperature-compensated Guillaume-type balance wheel and a constant-force fusee-and-chain transmission system.

Entirely visible from the dial side, this movement is housed a new 44 mm-diameter 18-carat gold case, especially conceived on this occasion.

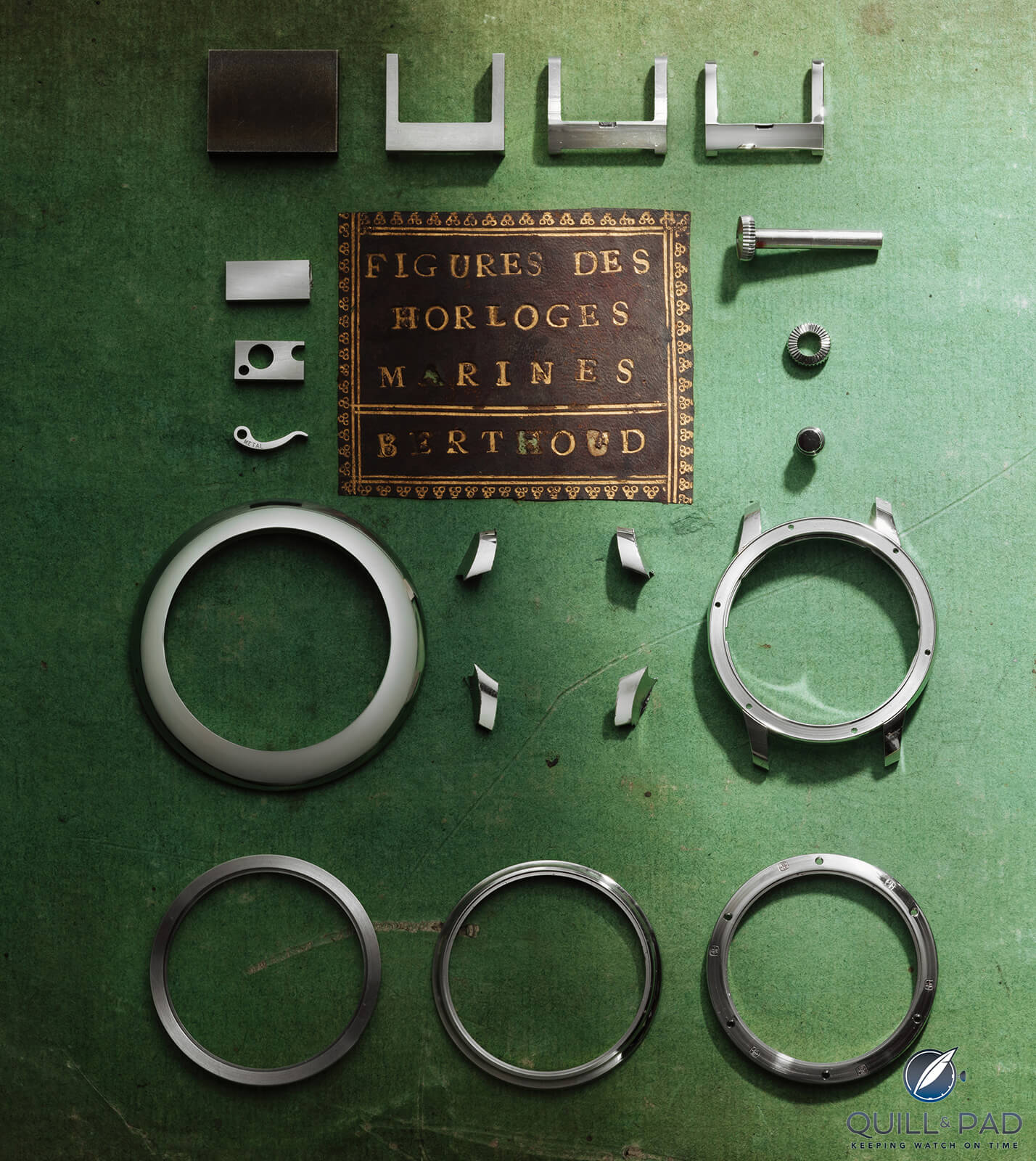

Making components for Naissance d’une Montre 3

A great deal of patience and time were devoted to bringing this piece of horological art to life. The creation of a dedicated workshop regrouping vintage machine tools and run by a passionate team of micro-mechanical engineers made it possible to produce the raw components without compromising on precision criteria and quality standards.

Making components for Naissance d’une Montre 3

In accordance with the regulations governing the Time Æon Foundation, each component of Naissance d’une Montre 3 has been individually crafted without digital assistance, entirely by hand or using traditional tools guided by the human eye, hand and mind.

After 11,000 hours of work and six years of dedication, the first result of this extraordinary project is now visible. Produced exclusively for Phillips in association with Bacs & Russo in Geneva, this one-of-a-kind stainless steel creation will be auctioned in November 2025. Part of the proceeds from the sale will be donated to a charity dedicated to preserving and passing on watchmaking expertise to future generations.

Preserving and transmitting craftsmanship

Naissance d’une Montre 3 aims to harness talents past and future, to gather their notes and sketches and to unite their knowledge in pursuit of a common goal: not the timepiece itself, but rather the preservation of all the expertise that brings it to life. It is clearly more important than ever to safeguard and transmit the traditional watchmaking skills required to produce mechanical timepieces.

This cross-disciplinary corporate project draws on all the Maison’s in-house expertise and know-how: design and engineering, laboratory, foundry, mechanics, micromechanics, jewellery, polishing, decoration and watchmaking.

In all, more than 80 Chronométrie Ferdinand Berthoud and Chopard artisans, specialists active in different crafts and locations (Fleurier and Meyrin) participated in the project. They worked and learned together with a common goal: finding solutions for crafting a timepiece entirely by hand, as well as documenting and referencing the entire production process.

A database comprising thousands of photos and videos was patiently compiled to illustrate and explain the methods used to create each component of the movement and the watch parts.

Naissance d’une Montre 3 is part of a tradition of learning and passing on watchmaking expertise, both of which were extremely important to Ferdinand Berthoud and his talented student and nephew Louis Berthoud (1754-1813). In 1812, the latter published a book recounting the watchmaking lessons he had given to the four students entrusted to him by the government, entitled “Entretiens sur l’horlogerie à l’usage de la Marine” [Discussions on Horology for use by the Navy].

Louis Berthoud concluded his account with the following sentence: “[…] to achieve great precision, they (Editor’s note: his students) need only time and experience […]” and concluded with the maxim: “AU TEMPS QUI INSTRUIT” [Dedicated to time, the great teacher].

The Naissance d’une Montre 3 project embodies the teachings of the master watchmakers who have left an indelible imprint on its history. In tribute to them, this maxim from Louis Berthoud is hand-engraved on the back of the movement.

Origins of an artwork

To bring the Naissance d’une Montre 3 project to fruition, a collection of vintage machine tools from the 1950s and 1960s were regrouped in a single area within the Manufacture in Fleurier: the Atelier Tradition. This entity encompasses a small team of micro-mechanical engineers responsible for producing the movement components without the use of computer numerical control (CNC) machines.

Highly skilled and passionate specialists spent many months defining the methods to be used in making these components and familiarising themselves with these conventional production tools. This was an essential step before ensuring that they could be produced in accordance with the project’s strict precision and quality criteria.

Making components on a vintage 1960 Schaublin lathe for Naissance d’une Montre 3

Among these machine tools, a 1960 Schaublin 102 single-axis lathe was dedicated to shaping circular components: arbors, fusees, pillars, pinions, wheels, barrel drums, studs, winding stems, screws, etc.

A 1960 SIP jig boring machine was dedicated to reaming, milling, drilling, grinding and tapping operations on various components: levers, mainplates, wheel plates, bridges and springs.

The figures speak for themselves: from the first sketch to the delivery of the first timepiece, nearly 11,000 hours of work were required. The 747 components in each movement, including 477 in the chain alone, are created individually.

Just cutting and polishing the pinion leaves using a pearwood grinding wheel involves an entire day’s work. Finishing a wheel takes three days.

Complex movement of Naissance d’une Montre 3 by Ferdinand Berthoud

Despite its simple geometry, the mainplate features 126 sinks of eight different diameters, 90 of which are polished using roller cutters, boxwood pegs and polishing pastes.

A host of challenges

Naissance d’une Montre 3 is an 11-piece limited-edition chronometer. The very first and only one of the series, featuring a stainless steel case, will be auctioned by Phillips in association with Bacs & Russo in November 2025. The next ten, made of 18-carat ethical gold, will be produced at a rate of two per year starting in 2026.

Case and buckle components of Naissance d’une Montre 3 by Ferdinand Berthoud

The 44 mm-diameter, 13 mm-thick case features curved sides, a wide fluted and engraved crown, a domed glass, a concave bezel and welded lugs. Inspired by Ferdinand Berthoud’s Astronomical Watch No. 3, these unique shapes are particularly difficult to craft using hand-operated machine tools.

Caseband and crown of the Naissance d’une Montre 3

To overcome these challenges, solutions were found within the Chopard group which encompasses the skills of many different trades. Certain processes such as lost wax casting used in jewellery making; or turning, milling, and tapping typical of micromechanics, enabled the Maison to leverage in-house expertise in producing the most complex shapes.

Back of the movement of Naissance d’une Montre 3

Once the raw component has been obtained, manual finishing trades take over: reworking the rough piece, trimming and polishing. Some components such as the lugs are then welded, before manual decoration (engraving and hallmarking) takes place.

This is also the first timepiece from Chronométrie Ferdinand Berthoud whose entire movement structure is visible on the dial side. Offset, between 1 and 2 o’clock, the hours and minutes are displayed on an open worked counter, revealing the essential components of the calibre: the barrel and fusee connected by a chain; the split bimetallic balance; a circular balance bridge supporting the shock absorber featuring two diamond endstones, one on the front and one on the back of the movement, like those of the Astronomical Watch No. 3; as well as a 50-hour power reserve indicator engraved on the mainplate.

Naissance d’une Montre 3 is an open book dealing with the themes of craftsmanship, watchmaking, history and of course precision.

Resistant to temperature variations

The balance of the Calibre FB-BTC.FC (an acronym for “Balancier Thermo-Compensé et Fusée-Chaîne”, meaning “thermo-compensated balance and fusee-and-chain mechanism”) is a chapter in technical history in its own right. Inspired by the Astronomical Watch No. 3, it returns to the essence of classic regulators from a century ago. It is a bimetallic Guillaume-type thermo-compensated split balance made of Invar and brass material.

It is equipped with four gold adjustment screws (for regulating the rate), two nickel silver adjustment nickel silver weights on the split rim (for regulating thermal compensation) and two fixed weights ensuring the inertia of the balance.

Balance bridge with diamond jewel and shock protection

A bimetallic balance maintains the oscillation frequency by compensating for the effects of temperature. The nickel-free steel alloy balance-spring is particularly sensitive to temperature changes, which affect its elasticity: when exposed to cold, the metal contracts and stiffens. This increased resistance tends to increase the oscillation speed of the balance and the movement gains time. When it is warm, the metal expands, causing the reverse effect.

However, thanks to its Invar-brass bimetallic composition with different expansion coefficients, the balance also reacts to the effects of temperature, but in the opposite way: when cold, the rims of the split balance open, increasing its diameter and therefore its moment of inertia. Its oscillation speed will tend to be slower, causing a delay in the movement.

When warm, the balance rims close, creating a gain. Temperature affects the balance-spring on the one hand and the bimetallic balance on the other in opposite ways: this is known as a Guillaume-type thermo-compensated split bimetallic balance, in tribute to the inventor of Invar alloy, Charles Edouard Guillaume (winner of the 1920 Nobel Prize for Physics).

To fine-tune the rating of the regulating organ, each steel balance-spring is custom-made for Naissance d’une Montre 3 before being blued, cut, pinned up to the collet, counted and centred by hand by the same specialist known as a “timer”. As bimetallic balances have virtually disappeared, along with the associated expertise, the adjustment of each movement thus equipped is a feat in itself.

Fusee-and-chain constant force system of Naissance d’une Montre 3

Calibre FB-BTC.FC features another signature element of Chronométrie Ferdinand Berthoud: a fusee-and-chain transmission system. Together, they smooth the torque from the barrel to deliver the most constant possible force to the balance. However, the construction of this mechanism is very different from other Ferdinand Berthoud movements. The fusee is equipped with a direct-drive stopwork system consisting of a an extremely robust cam and finger piece, based on a technical drawing by the illustrious watchmaker Breguet.

Similarly, the chain was specifically developed for the Calibre FB-BTC.FC. It measures 172 mm in length and comprises 477 components, including a hook and 285 links that are thinner than those used in other contemporary constant-force movements from Chronométrie Ferdinand Berthoud. Assembling each link by hand using 191 pins with a diameter of no more than 0.30 mm is a challenge.

Mainspring barrel cap and click (ratchet) of the Naissance d’une Montre 3

The barrel also features an original design. It is equipped with a traditional toothed ratchet system and a pawl required by watchmakers to pre-tension the mainspring.

Unlike other FB calibres with a fusee-and-chain transmission system, the FB-BTC.FC movement does not feature a differential gear for winding. In normal operation, the barrel pulls on the chain, turning the fusee clockwise and providing the energy needed to power the watch. During manual winding of the movement, the fusee rotates counter clockwise, suspending the transmission of power to the finishing gear train.

To prevent the watch from stopping during this operation, a winding pawl and an auxiliary spring – both integrated into the fusee – provide torque that enables the movement to continue running for approximately 30 minutes.

Endowed with a 50-hour power reserve, Calibre FB-BTC.FC measuring 37.50 mm in diameter and 8.35 mm thick is relatively compact, despite the space occupied by the fusee and chain. It is fitted with 37 jewels and two genuine diamonds acting as endstones for the balance-staff.

Housed at the heart of shock absorbers specially developed for this timepiece, they protect the balance-staff from breakage in the event of accidental impacts. These two gems are visible on the dial and caseback, recalling the historical heritage of Naissance d’une Montre 3.

A display highlighting the mechanism

The bridges and plates are made of sandblasted nickel silver and assembled with stylised polished steel pillars. The sides of some of the bridges have been carefully chosen and mirror-polished to highlight certain key elements of the movement.

Dial side close up of the Naissance d’une Montre 3

The Chronomètre Naissance d’une Montre 3 features two distinct dials, crafted from 18-carat white gold and engraved by hand. The first dedicated to displaying the hours and minutes is off-centre to between 1 and 2 o’clock. The other – positioned on the periphery of the watch in the form of a raised flange supported by pillars – displays the seconds.

Like the Astronomical Pocket Watch No. 3, the hours and minutes dial displays the hours with Roman numerals and the minutes using Arabic numerals. In the same spirit, their associated hands are also differentiated: the minutes hand ends in a bevelled tip, while the hours hand is arrow-tipped.

Flame-blued second hand of the Naissance d’une Montre 3

The flame-blued steel seconds hand occupies the centre of the movement. Its extreme thinness and over 25 mm length require unfailing concentration and dexterity at every stage of its production, including its final fitting, driving into a long, thin 18-carat gold pipe.

Hand making a hand for the Naissance d’une Montre 3

It takes nearly two days of work to make the flame-blued steel hours hand alone, a process involving no fewer than 54 micromechanical operations, plus 13 more devoted to decoration.

Finely crafted down to the smallest detail

Naissance d’une Montre 3 is not just about the timepiece itself; every detail of this project has been meticulously thought through. This approach notably applies to the strap, including the leather used to make it, as well as the refined and comfortable pin buckle securing it firmly to the wearer’s wrist.

Beautifully hand-crafted buckle of the Naissance d’une Montre 3

The entire buckle and its prong – the pointed mobile part featuring complex geometry – are handcrafted from the same material as the case.

Naturally a hand made watch needs a hand made leather strap

The leather strap is finely fashioned in the purest tradition of leather goods, from selecting hides to various stages of artisanal workmanship: cutting, marking, perforating, rolled-edging, stitching, fitting the loops, lining and finishing.

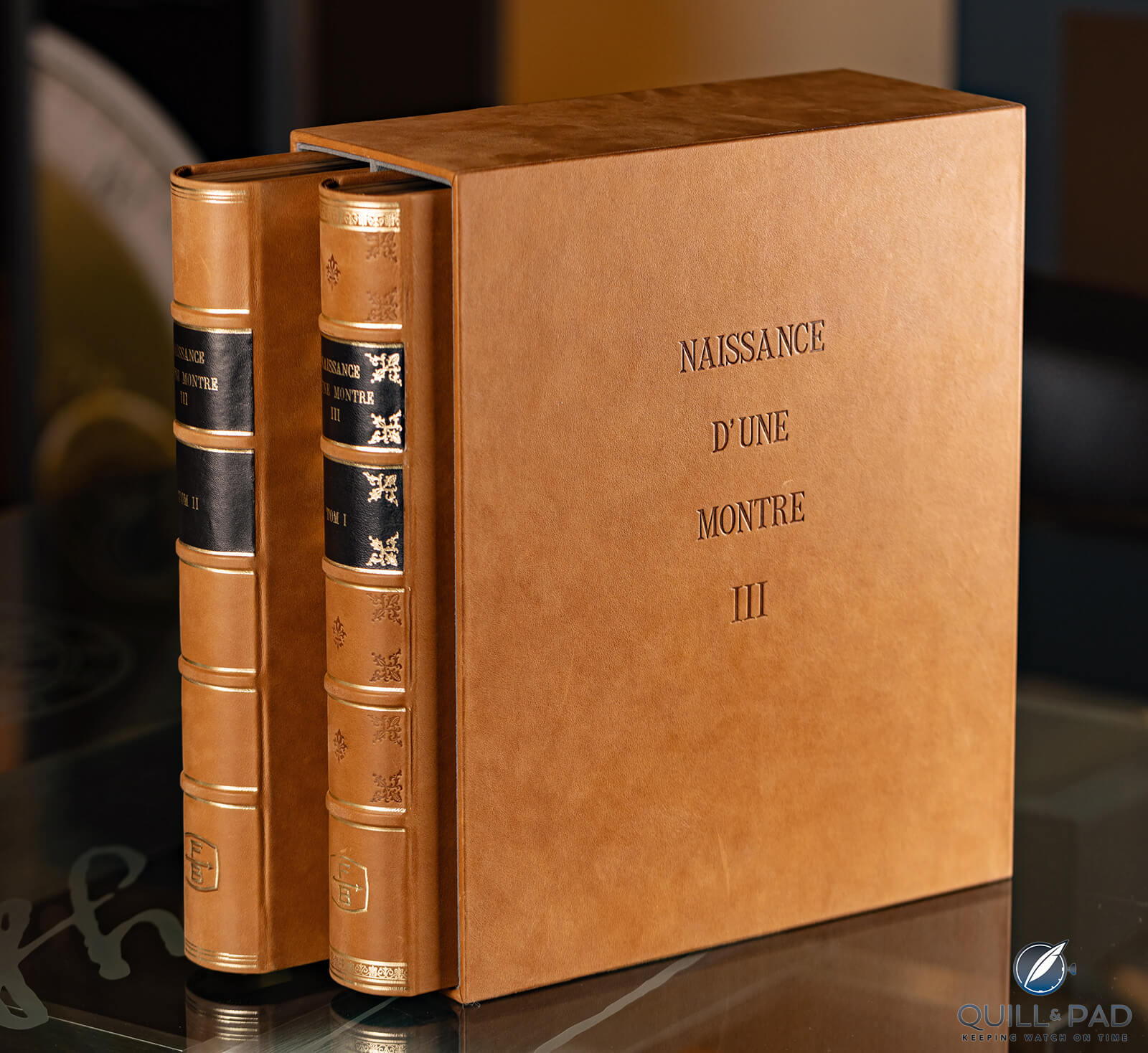

The Naissance d’une Montre 3 presentation box is inspired by the treatises on watchmaking written and published by Ferdinand Berthoud in the 18th century. It consists of two large books made of wood covered in calfskin, enhanced with lettering as well as embossed and hot-stamped decorations.

The presentatopn cases of Naissance d’une Montre 3 are two finely hand crafted ‘books’

The first volume houses the watch, while the second contains its certificates of origin, warranty and chronometry, as well as a blue calfskin travel pouch, a USB stick, a high-quality cotton cloth and a pair of gloves. It also accommodates a handcrafted 925 silver magnifying glass with a sapphire lens and walnut handle.

Beautifully hand finished movement of the Naissance d’une Montre 3

From traditional skills to contemporary tolerances

Although made by hand using traditional methods, Naissance d’une Montre 3 meets the same standards and values of fine workmanship established by Chronométrie Ferdinand Berthoud at the time of its launch in 2015.

The operating tolerances of Calibre FB-BTC.FC must match those of its counterparts equipped with modern regulating organs in order to pass the COSC tests and earn official chronometer certification.

In addition, the quality control of the decorations is carried out using a 6.7x magnifying glass, according to the same criteria as all other Chronométrie Ferdinand Berthoud models.

Naissance d’une Montre 3 by Chronométrie Ferdinand Berthoud

“Naissance d’une Montre 3 is a true tribute to watchmaking expertise”, says Karl- Friedrich Scheufele, President of Chronométrie Ferdinand Berthoud. “For more than six years, artisans from across the Chopard group, with perseverance and experience, committed themselves to a mission to master the traditional watchmaking skills required to create this extraordinary timepiece. On the tenth anniversary of Chronométrie Ferdinand Berthoud, we could not imagine a more fitting tribute to the Master Watchmaker, who dedicated his career to developing the most accurate timepieces of his time and sharing his knowledge.”

About “Naissance d’une Montre”

The “Naissance d’une Montre” initiative was launched in 2009 It is a collective watchmaking project involving several watch Maisons and artisans nurturing the joint aim of safeguarding traditional Haute Horlogerie skills. Unique in the world, this legacy mission is based on extensive research and documentation, backed by the provision of resources that will in turn enable contemporary watchmakers to transfer this endangered heritage. All their work is recorded in the Time Æon Foundation specifically created for this purpose,

“Naissance d’une Montre” is built chapter by chapter through the creation of timepieces designed, produced and decorated using these traditional methods. Each timepiece results from the work of a multidisciplinary team entirely dedicated to it.

The first chapter of this project –”Naissance d’une Montre 1“, led by Robert Greubel, Stephen Forsey and Philippe Dufour alongside Michel Boulanger – called for six years of work, from 2009 to 2015. The first timepiece in this series of ten watches was sold by Christie’s in 2016 for a record price of over USD 1 million.

The second chapter involved Robert Greubel, Stephen Forsey, Felix Baumgartner and Martin Frei, along with two young watchmakers, Dominique Buser and Cyrano Devanthey. Six years of work, from 2015 to 2021, were required to create a one-of-a-kind “Naissance d’une Montre 2” model that was also auctioned.

“Naissance d’une Montre 3” is the third chapter, based on an intense collaboration between the artisans at Chronométrie Ferdinand Berthoud and Chopard.

Fore more information, please visit www.ferdinandberthoud.ch/en

Quick Facts: Naissance d’une Montre 3 by Chronométrie Ferdinand Berthoud

Ref. FB 4BTC.1

Case

Handcrafted domed round case in 18-carat white gold

Total diameter: 44.30 mm

Thickness: 13 mm

Lug width: 22 mm

Water resistance: 30 metres

Crown diameter: 8.80 mm

Handcrafted fluted 18-carat white gold crown with hand-engraved “FB” logo

Handcrafted exhibition back in 18-carat white gold, secured by 8 screws and fitted with a glare-proofed sapphire crystal pane

Glare-proofed, domed sapphire crystal glare-proofed on both sides

Precious material: ethical gold certified by the RJC Chain of Custody.

Dial

Handcrafted in 18-carat white gold

Hours and minutes dial, circular satin-finished, indicating the hours with hand-engraved Roman numerals and the minutes using Arabic numerals

Circular satin-finished seconds ring

Power-reserve indication with “0” – “1” hand-engraved on the mainplate

Hands

Handcrafted in steel blued by traditional heat treatment

Arrow-tipped hours hand

Bevel-tipped minutes hand

Filaire-type bevel-tipped seconds hand with steel counterweight, with 18-carat gold pipe

Arrow-tipped power-reserve hand

Strap and buckle

Hand-stitched rolled-edge alligator leather strap (width 22/18, length 125/070) – Different lengths and colours available on request

Handcrafted 18-carat white gold pin buckle

Functions

Hours and minutes between 1 and 2 o’clock, central seconds, power reserve and balance-stop function

Movement

Production: Handcrafted

Mechanical hand-wound Calibre FB-BTC.FC

Outer diameter: 37.50 mm

Case diameter: 35.80 mm

Thickness: 8.35 mm

Jewels: 37

Diamonds: 2

Frequency: 3 Hz/ 21,600 vph

Power reserve: 50 hours

Limited edition: 11 movements

Technical specifications

Movement with fusee-and-chain transmission system (constant force) and thermo-compensated bimetallic balance.

Fusee: traditional direct-engagement stopwork system

Barrel: traditional toothed ratchet pawl system

Balance-stop function: traditional system consisting of a control, a lever and an arbor

Shock absorber – original system with diamond endstones

Guillaume-type thermo-compensated split bimetallic invar-brass variable-inertia balance, incorporating four 18-carat gold adjustment screws, two adjustable gold-plated nickel silver weights on the split rim and two fixed weights.

Traditional blued carbon steel balance-spring with Phillips terminal curve

Swiss lever escapement

Fusee-and-chain bridge on back of the movement bearing various hand engravings: “AU TEMPS QUI INSTRUIT – FERDINAND BERTHOUD – CHRONOMÈTRE VAL-DE-TRAVERS SUISSE – 39 PIERRES”

Hand-finished exclusively using traditional tools in accordance with the highest watchmaking standards

Time setting: crown in position 0: stem inactive, position 1: manual winding, position 2: time setting and balance-stop function

Components: 747 (including chain)

Bridges and mainplate: 13 bridges + 1 mainplate in nickel silver

Bridge-securing screws: 19 in steel and 4 in heat-treated blued steel

Pillars: 11 in steel

Gears: 10 in CuBe

Chain: 477 steel components

Chain length: 172 mm

Balance :12.56 mm diameter

Balance components: 18 components

Officially chronometer-certified by the COSC

You might also enjoy:

A Hero’s Journey Begins And Ends: Naissance d’Une Montre, Le Garde Temps

Leave a Reply

Want to join the discussion?Feel free to contribute!

So often, we are shown these untouchable pieces in a way that doesn’t make sense, or with photographs that don’t allow us to appreciate the achievement. Not here!

Thank you very much for this article.