by Martin Green

Whereas most brands are very focused on the commercial sides of their enterprises, Parmigiani Fleurier seems to have a more relaxed approach to things. It does not release an endless stream of new watches but rather lets its collections mature and evolve.

Added to this is an exceptional quality of movements, cases, dials, and overall finishing.

Michel Parmigiani at work

But even in the watch world, no miracles happen alone; nearly every watch company needs suppliers. Parmigiani Fleurier, in Switzerland’s Val de Travers, is special: it has the advantage of being part of the Sandoz Family Foundation.

Parmigiani Fleurier’s headquarters in Fleurier

The foundation was formed in 1964 by Edouard-Marcel Sandoz, who was the son of the founder of Sandoz SA of Basel (now Novartis SA, one of the most significant global players in the pharmaceutical industry).

The Sandoz family, which owns one of the most important horological collections in the world, is known to be very passionate about watchmaking. Alongside Parmigiani Fleurier, the family foundation is also involved in five other companies in the watch industry: Vaucher Manufacture, Atokalpa, Elwin, Les Artisans Boîtiers, and Quadrance & Habillage.

The Swiss watchmaking town Fleurier

Vaucher Manufacture: it’s all about movements

Another of the well-known companies under the umbrella of the Sandoz Family Foundation, at least for watch enthusiasts, is Vaucher Manufacture Fleurier. Its high-tech premises located on the outskirts of the charming town of Fleurier focuses entirely on the development and production of high-quality mechanical movements and associated modules.

Vaucher Manufacture

Created in 2003, Vaucher has become a player of great significance in the watch industry. As movements by other high-end producers such as ETA, Frédéric Piguet, and Jaeger-LeCoultre are largely limited for use within the groups they belong to, Vaucher is one of the very few “independent” movement producers. Though as a member of the Sandoz Family Foundation, it boasts a naturally close relationship with Parmigiani Fleurier of course.

Vaucher, who supplies a variety of high-end watch brands with high-quality movements, mixes traditional crafts with cutting-edge technology in its production processes.

Whatever yields the best results is generally how Vaucher directs its efforts. Sophisticated and advanced CNC machines dominate one room, but just down the hall an artisan is likely hand-beveling a bridge, for example.

Watchmakers at Vaucher Manufacture

A significant part of the company’s resources goes into research and development. This strengthens its position within the industry. And that of Parmigiani Fleurier, whose own movements are generally manufactured in the Vaucher factory.

Other companies indulging in these beautifully crafted calibers often keep it a secret, but alongside Parmigiani Fleurier it is common knowledge that both Richard Mille and Hermès are loyal clients, the latter a 25 percent shareholder of Vaucher.

As something of a win-win thanks to such partnerships, Parmigiani is the only other watch company able to indulge in the pleasure of outfitting its watches with Hermès leather straps.

Atokalpa: a horological philosopher’s stone

Have you ever heard of a company called Atokalpa? Most likely not. But rest assured it is an essential part of both the Sandoz Family Foundation and Parmigiani Fleurier.

Located in a rather nondescript building in a small industrial area of the Swiss town of Alle, surrounded by prime farmland, it seems a bit out of the way of the traditional watchmaking centers. But that hasn’t prevented Atokalpa from becoming an expert in the production of watch gears.

Stamping out gears for watch movements at Atokalpa

Utilizing traditional methods in use for centuries, Atokalpa also benefits from cutting-edge approaches like laser-cutting technology.

Being part of Parmigiani’s watchmaking hub has a significant advantage that goes beyond financial resources and synergy with sibling companies: what Atokalpa also receives is the time to further develop the company and invest in technology, skills, and research and development.

Atokalpa’s declared aim doesn’t appear to be year-on-year double-digit growth, but rather to continually increase quality and depth.

Making a balance spring at Atokalpa

The Sandoz-owned companies that make up the Parmigiani group are afforded the time to grow organically and to focus on obtaining and retaining as much knowledge and skill as possible.

Assembling and regulating an escapement’s pallet fork at Atokalpa

For Atokalpa, this meant that in 2006, six years after it was acquired by the Sandoz Family Foundation, it was able to finally make all the components needed for the regulator in-house.

This also included the watchmaking equivalent of the philosopher’s stone: the balance spring. Some of the most respected companies in the industry still haven’t mastered this, so having the ability within the group is – needless to say – a major asset.

Screw it! Enter Elwin

High-end watchmaking puts importance on every single detail. A visit to Elwin makes that abundantly clear.

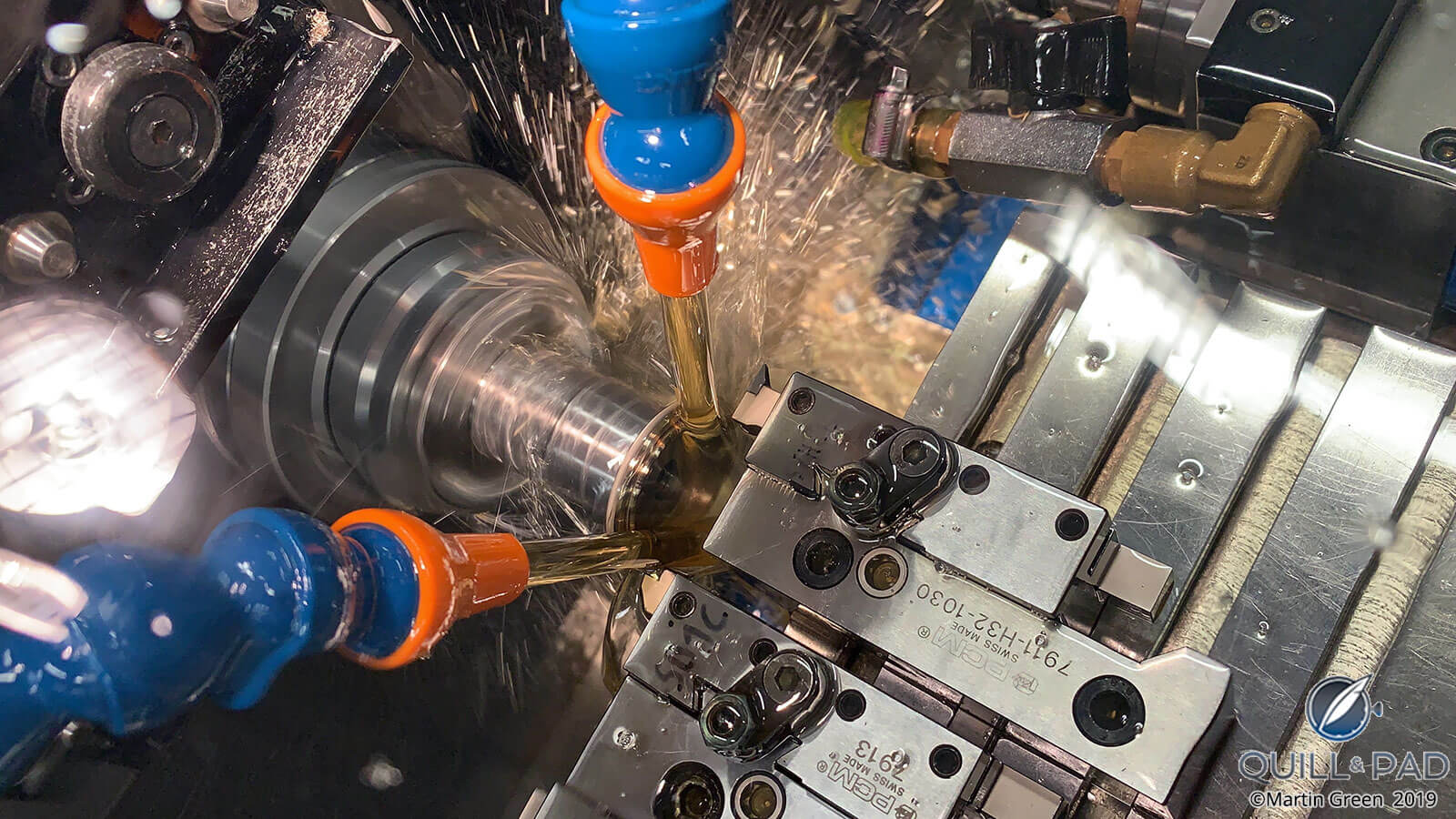

Some high-precision long lathes at Elwin

Elwin, with a staff of just 20, consists mainly of one large hall full of long lathes for making components – like screws – that are so small they can hardly be seen by the naked eye. Their tolerances are measured in microns.

Scale of the components that Elwin manufactures

What makes Elwin so unique is that it not only has the machines to create these parts but also has developed the software to control them. This gives Elwin and its partners almost endless possibilities in the production of components. And it guarantees very high quality.

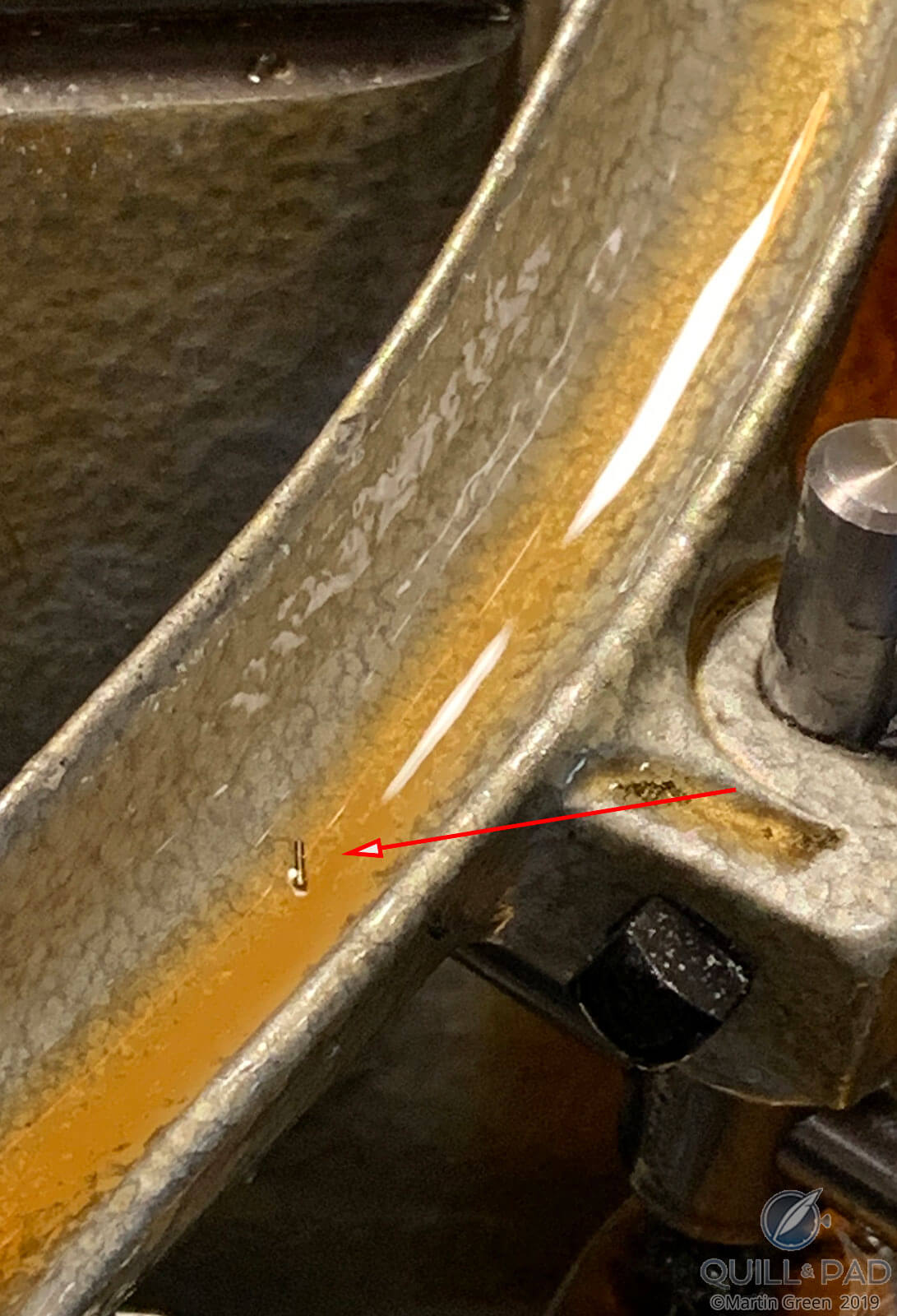

A miniscule component sliding out of a massive lathe at Elwin

Such skills are also very much in demand outside the group’s companies, so Elwin’s client list reads like a Who’s Who of the high-end watch industry.

Companies like Elwin also make the case that a watch cannot be genuinely luxurious if not all of its components are of the best quality. There are cheaper ways to produce screws, for example, but their fit, strength, and quality will never be the same level.

Les Artisans Boîtiers and Quadrance & Habillage: looks are everything

Movements often make the watch, especially at the level where Parmigiani Fleurier operates. But it is the cases and dials that give a watch its visual impact.

Within the Sandoz Family Foundation, there are two very specialized companies focusing on the production of these parts.

Heating a platinum watch case at Les Artisans Boîtiers

Les Artisans Boîtiers, who joined the foundation group in 2000, does the entire process of case making from design to finishing. With the help of three-dimensional software and printers, these technicians work on the next generation of cases both for Parmigiani Fleurier and other clients.

CNC machine making a watch case at Les Artisans Boîtiers

Large CNC machines make these designs come to life as they cut, shape, and mold from bars of metal. A lot of emphasis is also put on the finishing of the cases, which is often what makes the difference between a good watch and a great watch.

Polishing a Parmigiani watch case at Les Artisans Boîtiers

Finishing cases requires a lot of skill, patience, and experience, which is why this is often one of the first things that watch manufacturers cut back on. If you ever wonder how good these people are, next time you have the opportunity you should certainly examine the complicated and beautiful case of one of Parmigiani’s signature watches: the Toric.

Parmigiani Fleurier Toric Capitole

The same can be said of Quadrance & Habillage, a company founded by the Sandoz Family Foundation/Parmigiani watch group in 2005 with the of aim enabling more creativity.

Applying indices to a dial at Quadrance & Habillage

Quadrance & Habillage’s area of expertise is watch dials. And its artisans master many different finishes, including being able to print nearly anything on them with astonishing accuracy. But the company’s real strength lies in the wide palette of colors in which it can produce its dials.

Colorful watch dial alchemy (aka galvanic baths) at Quadrance & Habillage

In a large, alchemist-lab like room, hot baths steam and bubble in the most exotic colors. Here every color of the rainbow (and a few more!) are created and consistently applied to dial blanks.

This may seem interesting yet insignificant in the large scheme of things, but it allows Parmigiani Fleurier to be limitless in terms of dial creation.

While Parmigiani Fleurier may be one of the smaller players in the watch world, together with its sibling companies it is a force to be reckoned with.

Parmigiani Fleurier Bugatti Type 390 Chiron

Yet total market domination has never been on the mind of Michel Parmigiani, nor was it ever the reason that he founded his company. For him, it was just a way to realize his vision of high-end watchmaking.

Parmigiani’s watches are more than the sum of their parts, and the same can be said of all the companies that are part of the Sandoz Family Foundation.

For more information, please visit www.parmigiani.com.

You may also enjoy:

How It’s Made: Inside The Breguet Castle Of Complications

You Are There: Video Tour Through The Armin Strom Factory

Leica Celebrates 100 Years: A Factory Tour In Wetzlar, Germany

Leave a Reply

Want to join the discussion?Feel free to contribute!

Enjoyed reading this, thanks.

Glad to hear this Gil! Thanks for letting us know!

Bom dia demais estes modelos.

Bom dia

My pleasure. There’s a really well-made ~1 hour docu-film that Parmigiani made about their facilities and the people who work there; seeing the way they give their employees such a high quality environment where they’re not just drones was a major factor in motivating me to get one of their watches.

This is it: https://www.youtube.com/watch?v=sOp4qvaJHOg

I really should have learned to use the ‘reply’ function by now, mon dieu. The comment above was meant as a reply to you, Martin.