by Bhanu Chopra

Until recently, Glashütte Original has had a relatively low profile among collectors. However, that’s changing. One factor contributing to an increased awareness was the purchase and integration of German dial manufactory Th. Müller based in Pforzheim, Germany several years ago.

Glashütte Original Sixties Green Panorama Date

Highlighting the change are the electrifying dials of the Senator Sixties Annual Editions.

I had the opportunity to tour the Glashütte Original dial factory in Pforzheim, a city based in southwestern Germany famous for its jewelry and watchmaking industry, a fact that has earned it the nickname Goldstadt (“gold city”). Here, more than 80 percent of the buildings were destroyed during Allied bombing in World War II. Pforzheim was rebuilt gradually and now accounts for nearly 70 percent of the total sales of German jewelry and silver wares.

Th. Müller has been manufacturing dials in Pforzheim since the early 1920s, supplying dials to various German and Swiss brands. It supplied Glashütte Original’s East German predecessor Glashütter Uhrenbetrieb since the 1950s, making for one of those anomalous east-west alliances one practically never hears about.

Vintage GUB ‘Glashütte Original’ from the 1960s with dial by Th. Müller

The classic GUB pilot-style dial and the 1960s Spezimatic dials, among others, were manufactured in this factory. Swatch Group (Glashütte Original’s parent company since 2003) purchased the Th. Müller dial factory in 2006, renaming it DZM (Deutsche Zifferblattmanufaktur) at that time.

In 2012 DZM was merged with Glashütte Original, becoming exclusive to that brand. The factory was relocated within Pforzheim in 2013 and renovated extensively.

Factory manager Michael Baumann guided me through the complex process of manufacturing dials. He explained that depending on the complications of a given watch model it takes 70 to 80 steps to manufacture a perfect dial.

The manufacturing is divided into the following major departments: dial blanks, surfacing, electroplating and galvanization, pad printing, and setting indexes and luminescence.

Dial blanks

Dial blanks are where the entire process begins, with externally sourced raw sheets of metal made of brass, bronze, and nickel silver (also known as German silver), which undergo an extensive machining process.

Sheets of brass waiting to be stamped into dial blanks at Glashütte Original

First, the dial blank is stamped from the sheet, a process achieved by a punching machine that cuts out the blank.

Stamping is repeated a few times to get the precise date and/or other complication windows cut from the blank.

Stamped out: Glashütte Original dial blanks

The stamping machines pre-define the shape of the dial and the cutouts; additionally, they can create complex patterns on the blanks.

The final step is to weld tiny feet to the back of the dial to attach it securely to the top of the movement. While there is lot of heavy lifting done by machines here, each step requires human intervention.

Grinding a moon phase dial at Glashütte Original

The tiny moon phases with glimmering blue, silver, or black colors are achieved by finishing with the diamond cutter and applying lacquer. The final lacquering process gives the dial its permanent luster.

Surfacing

The surfacing department gives the dial that polished shine reflecting different colors under different lighting. This includes the labor-intensive sandblasting, sunray-brushing, and lacquering.

Applying sunray finish to a Glashütte Original Seventies dial

First, the prepared blank is hand-machined with an abrasive material to give it the desired finish, which could be a perfect mirror polish or a brushed finish.

Electroplating and galvanization

Glashütte Original invested in modern technology for electroplating, which creates a high-quality galvanized dial surface.

Electroplating begins with polishing and cleaning the dial as thoroughly as possible before the process starts. The finished product will appear uneven and smudged if the surface is dirty, oily, scratched, or otherwise damaged.

Dials in a galvanic bath at Glashütte Original

Modern electroplating begins with the creation of a metal salt using the plating metal, typically gold or silver. Salts are formed when an acid and a base combine to create a neutralization reaction; metal salts are formed when positively charged metal ions are combined with an acid or a nonmetal. This salt is then placed in water to form a bath for the dial.

The dial is then immersed in this bath and an electric current applied. The current dissolves the metal salts as it moves through the bath. Gold/silver molecules ride the current and are deposited onto the dial. The thickness of the plating is determined by how long the dial is left in the bath.

Glashütte Original Sixties Iconic Red with dégradé dial

With the use of this modern electroplating process, Glashütte Original has endless possibilities to produce colorful and exotic dials. But this is not to say that traditional methods are abandoned for modern machines. Glashütte Original also employs traditional hand-painted techniques on certain elaborate dials.

Milling the hour markers on a Glashütte Original Sixties dial

After galvanization

The hour markers of the Sixties dials are cut into the surface of the blank after galvanization as demonstrated above.

Pad printing

But most other dials have pad-printed markings. The process of printing indexes and numbers was the most intriguing to me as this is the part the eye most comprehensively takes in. Glashütte Original uses the pad printing method, in which a large rubber balloon (known in the jargon as the “tampon”) “stamps” the dial with a precise imprint. Joshua Munchow describes this process in minute detail in Focus On Technology: Pad Printing.

Pad printing at Glashütte Original’s dial maker in Pforzheim, Germany

The same process is used for printing date disks and chapter rings. Each dial must be checked for accuracy before it can move to next step.

Setting indexes and luminescence

Setting indexes and applying lume are tedious, labor-intensive processes.

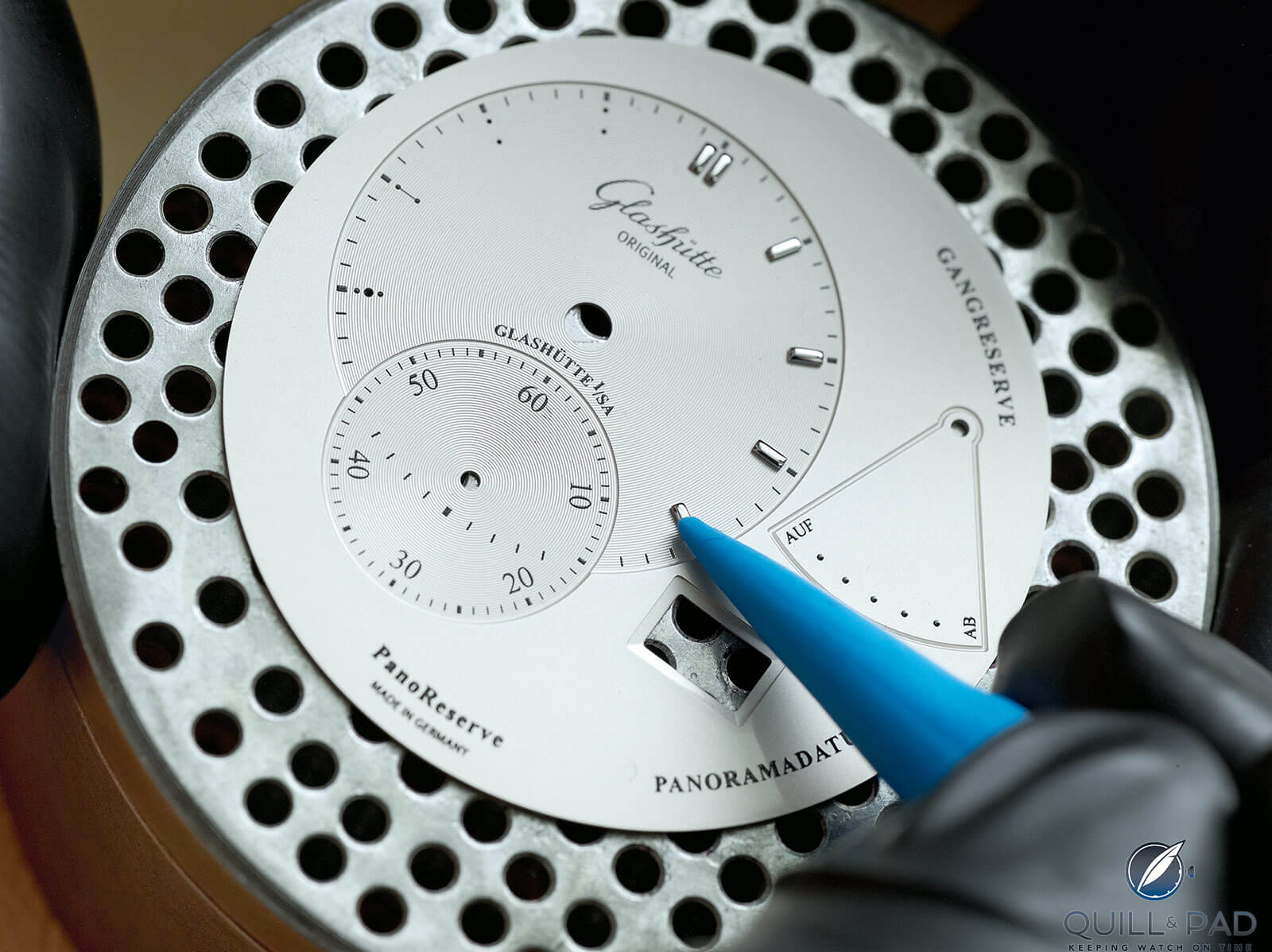

Setting polished hour indexes on a Glashütte Original PanoReserve dial

Each tiny applied index is set precisely on top of the printed index marker.

Applying Super-LumiNova to dial indexes at Glashütte Original

If luminescence is needed, one or more coats of C3 Super-LumiNova are then applied to the indexes and numerals depending on the watch model.

Conclusion

Glashütte Original takes great pride in its quality control. When a new trainee joins the factory, his or her first duty is to spend many months in the quality control department to observe the quality of the finished dials.

Dial quality control at Glashütte Original

Each week, the dials are loaded on to the delivery van and driven the 600 kilometers to Glashütte for assembly and further quality control.

The growth of the Glashütte Original dial factory is clearly visible, and it is good for both Pforzheim and watch collectors.

The Glashütte Original Sixties Iconic collection at its debut in 2015

Visitors are welcome to visit the Glashütte Original dial factory and, if you are visiting the area, you might want to plan a day trip to the Porsche and Mercedes museums in Stuttgart. I can heartily recommend them!

For more information, please visit www.glashuette-original.com/manufactory/dial-manufactory.

You may also enjoy:

Focus On Technology: Pad Printing

Sixties Iconic: Glashütte Original’s Richly Multicolored Homage To Vintage East German Style

Glashütte Original Sixties: Retro Chic Returns In A Stylish New Green

Leave a Reply

Want to join the discussion?Feel free to contribute!