The AgenGraphe By Agenhor: The Most Significant Chronograph Since . . . Since The Invention Of The Chronograph

by Ian Skellern

Chronographs are the most popular wristwatch complication, and for many the most useful.

Since the invention and creation of the first chronograph by French horologist Louis Moinet in 1816 (see Discovery, Firsts, And The Louis Moinet Compteur De Tierces and History Rebooted: The Chronograph’s Inventor Is . . . Louis Moinet!), there have been quite a few well deservedly acclaimed chronographs, many inspiring near cult-like devotion.

However, as of today, all of these great chronographs have been rendered obsolete.

By all means keep your Datographs, El Primeros, Valjoux 7750s, Ref 5370Ps (sorry, Gary! See Why I Bought It: Patek Philippe Reference 5370P), Daytonas, and Speedmasters if your taste lies in now-outdated, near-future museum pieces.

AgenGraphe automatic chronograph movement by Agenhor

With the AgenGraphe, Agenhor presents the future of chronographs.

Here are ten drawbacks of conventional automatic chronographs

Since the invention of the chronograph more than 200 years ago, very little has changed as even a cursory glance of the dial of Moinet’s Compteur de Tierces illustrates. Sure there have been mechanical tweaks here and there, better materials, and miniaturization. But not much else.

Chronographs have had the following drawbacks for more than 200 years:

1. Small subdial counters = poor legibility.

Because all chronograph movements pre-AgenGraphe have had a central pinion driving central hands, the chronograph counters have had to be small in diameter to fit inside the radius of the movement.

It should be noted that De Bethune was one of very few brands to address this issue with the MaxiChrono, which had five coaxial central hands, but the sheer number of hands displaying on the same axis caused its own legibility problems (see Two Very Different Chronographs Launch At Baselworld: Glashütte Original And De Bethune).

2. Multiple dials = poor legibility.

Reading the elapsed time over multiple subdials – hours, minutes, and seconds for example − is not intuitive. We have the habit of reading these indications together around the same dial as we do on a standard three-handed watch.

And the fact that most chronographs have counters utilizing different-sized dials − large central seconds, for example, with minutes and hours on small subdials − makes it even harder to intuitively calculate the elapsed time.

3. Analogue minute indications = poor legibility.

On most traditional chronographs with small minute subdials it can be difficult to tell whether the minute has moved to the next minute or not when the chronograph second hand is near 12 o’clock.

Note: engaging a chronograph mechanism is like changing from neutral to engaging a gear in a manual transmission (stick shift) car: you need a clutch. In the case of a chronograph, the clutch is engaged by the pusher. The two most common types of chronograph clutches are named for the direction they move in when engaging − vertical and horizontal − and each has advantages and disadvantages.

It’s also worth noting that a column wheel is just a switching mechanism used to activate the clutch and has no bearing on whether the clutch is horizontal or vertical.

4. Horizontal clutch = stutter.

With a horizontal clutch, the toothed gear wheel turning the main second hand rotates horizontally to mesh with the gear turning the chronograph’s second hand. Because the main seconds’ gear is rotating and the chronograph seconds’ gear is stationary, the teeth in the two gears don’t always mesh smoothly. This causes the chronograph’s second hand to stutter slightly when it starts.

The videos above and below show the toothed gearing of a horizontal chronograph clutch in operation.

Another drawback to the horizontal clutch is that the drag generated by the clutch drops the amplitude of the balance wheel, which reduces the accuracy of the timing and the teeth wearing as they engage.

However, horizontal clutches are the most popular because brands mitigate the main drawbacks with engineering, and in comparison to vertical clutches they are relatively cheap to make, easier to service, take up less space, and look good through a display back (if not obscured by a winding rotor). High-end brands like A. Lange & Söhne can mitigate those drawbacks through precision engineering.

5. Varying power requirements when the chronograph is operating = varying power available to the regulator, so the amplitude of the balance is rarely constant.

This leads to reduced precision for both the time and the elapsed time.

6. Vertical clutch = more expense.

A vertical clutch lacks the good looks of a horizontal clutch, takes up more space, is more expensive to manufacture, and is more difficult to service.

However, its main advantage is that chronograph gearing is integrated into the going train of the movement so it is permanently meshed and the chronograph starts smoothly. Being permanently meshed also reduces wear, and permanent engagement also means there is little drop in balance amplitude when the chronograph is activated, so precision is unaffected.

7. Excessively strong forces = increased wear.

To minimize the risk of both horizontal and vertical clutches being disengaged while operating due to shocks, they are held together with otherwise unnecessary strong forces, which increases wear.

8. Strong reset force = shock.

A strong force must be applied to to reset the chronograph via the pusher, which leads to a quite violent reset shock for the chronograph’s second hand.

Understandably, reset shocks create wear, stress components, and lead to more frequent servicing and after-sales repairs.

9. Automatic winding = conceals mechanical beauty.

With their multitude of intricately interacting components and mechanisms, chronograph movements are perhaps the most beautiful to appreciate, especially in operation. Unfortunately for aficionados of the genre, the majority of chronograph movements feature automatic winding, and the large winding rotor usually covers 50 percent of the beautiful caliber underneath.

10. Automatic winding = noisy.

Automatic winding mechanisms are relatively noisy, especially those running on ceramic bearings. And ceramic bearings are particularly sensitive to the slightest dust particles.

Who would have thought the ubiquitous chronograph suffered from so many problems? Familiarity does not always breed contempt, but it does encourage acceptance of adverse traits that we might not otherwise endure.

If only somebody could come up with a way to address not just one, or a few, of the above-mentioned issues plaguing chronographs, but resolve all of them.

Well finally, after 200 years, somebody did: Agenhor!

Who is, what is, Agenhor?

Agenhor is a family-owned movement manufacturer based in Geneva, Switzerland, founded in 1996 by Jean-Marc Wiederrecht and his wife Catherine. Their sons Nicolas and Laurent both work for the company.

In 2007 Jean-Marc Wiederrecht received the inaugural Best Watchmaker award from the Grand Prix d’Horlogerie de Genève.

While Agenhor tends to work behind the scenes for the prestigious brands that form the company’s clients, the watches and movements Agenhor has developed are as prodigious as they are impressive. These include:

Harry Winston Bi-Retrograde Perpetual Calendar (in 1989 it was the world’s first)

MB&F HM2 and HM3

Happy Winston Opus 9 (Best Design GPHG 2009, see The Harry Winston Opus Series: A Complete Overview)

Van Cleef & Arpels Pont des Amoureux (Best Ladies’ Watch GPHG 2010)

Hermès Temps Suspendu (Best Men’s Watch GPHG 2011)

Fabergé Lady Compliquée Peacock (Best Ladies’ Complication GPHG 2015, see Fabergé Inaugurates Rebirth With Exceptional Lady Compliquée)

Fabergé Visionnaire DTZ (Best Travel Time Watch GPHG 2016, see Fabergé’s Visionnaire DTZ: A Surprising Way To Display A Second Time Zone)

Presenting the AgenGraphe AGH-6361 automatic chronograph movement by Agenhor

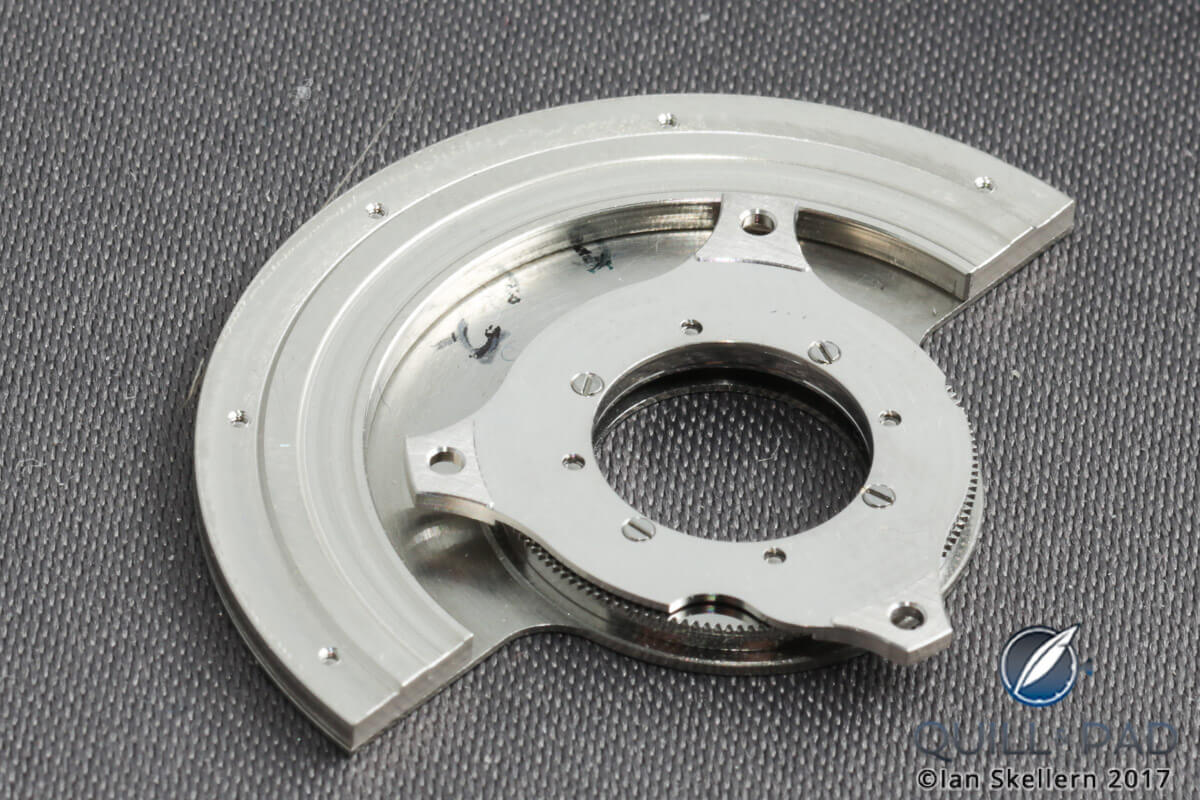

In 2016, Agenhor presented a movement with a hole in the center that, while revolutionary, gave little hint as to what might follow. The automatic movement was basically a wide ring, and it was remarkable for the fact that it was empty in the center and had a rotor on the dial side rather than the back.

The Agenhor chronograph movement without the central chronograph module

When I first saw this movement, Wiederrecht explained to me that the idea was that center of the patented movement could contain either some type of static artwork or a complication module.

Van Cleef & Arpels Poetic Wish

The base movement first saw light of day in 2012 in the Van Cleef & Arpels Poetic Wish featuring a five-minute repeater.

Fabergé Visionnaire DTZ in pink gold

In 2016, Fabergé presented the award-winning Visionnaire DTZ featuring a dual time zone indication in the center of the base movement (see First Look: The Surprising Movement Of The Fabergé Visionnaire DTZ and Fabergé’s Visionnaire DTZ: A Surprising Way To Display A Second Time Zone).

To give you an idea of the time scales involved in the development of the world’s most advanced chronograph, the movement with a hole in the center was patented in 2002, 15 years ago. And work on a chronograph that made full use of the new movement began more than 12 years ago, and has had developers working on it full-time for more than three years.

Legibility and practicality

The initial key concepts for the AgenGraphe chronograph included having the elapsed time indicators displaying around the center hole so that the indications were large and highly legible, and that the minute and hour displays jumped instantaneously so that there could be no confusion when reading elapsed time.

Legibility and practicality were the highest priority. In pursuit of those dual goals over the following years everything else fell into place.

Legibility

Thanks to the elapsed time indications − hours, minutes, and seconds − displayed around relatively wide-diameter chapter rings around the center of the dial, the chronograph’s elapsed time can be read both easily, thanks to the generous diameter of the displays, and intuitively because the hours, minutes, and seconds of the elapsed time are read exactly like the hours, minutes, and seconds of the standard three-handed clocks and watches we are are all so used to.

Mock-up of hour, minute, and second chronograph hands fitted to Agenhor’s AgenGraphe movement

There is no need for reading and calculating the elapsed time from multiple dials; you can instantly see the measured time simply by the location of the chronograph hands.

And the fact that the hours and minutes jump instantaneously ensures that there are no errors in reading the elapsed time when the hands are near the top of the dials.

Maximum visual appreciation thanks to a no-ball bearing winding rotor

With the automatic winding rotor on top of the movement, there is nothing to block full visual appreciation of the chronograph activation mechanisms on the back of the movement.

And that winding rotor is silent so there’s no annoying sound to distract from appreciating the show. That lack of noise is due to the fact that the rotor is not supported by a ball or roller bearing, but a bearing without any balls or rollers: just two low-friction metal plates sliding over each other on a thin film of oil.

A ball-less bearing supports the automatic winding rotor on Agenhor’s AgenGraphe

A platinum weight on the rotor provides maximum mass for maximum efficiency.

A minimum of components for maximum reliability . . . and it’s silent!

The meat in the sandwich: the AgenClutch

But the real magic of the Agenhor chronograph lies in the central heart of the movement, which contains a patented chronograph clutch − the AgenClutch eliminating all drawbacks of both horizontal and vertical clutches.

The patented AgenClutch engages and disengages the chronograph mechanism

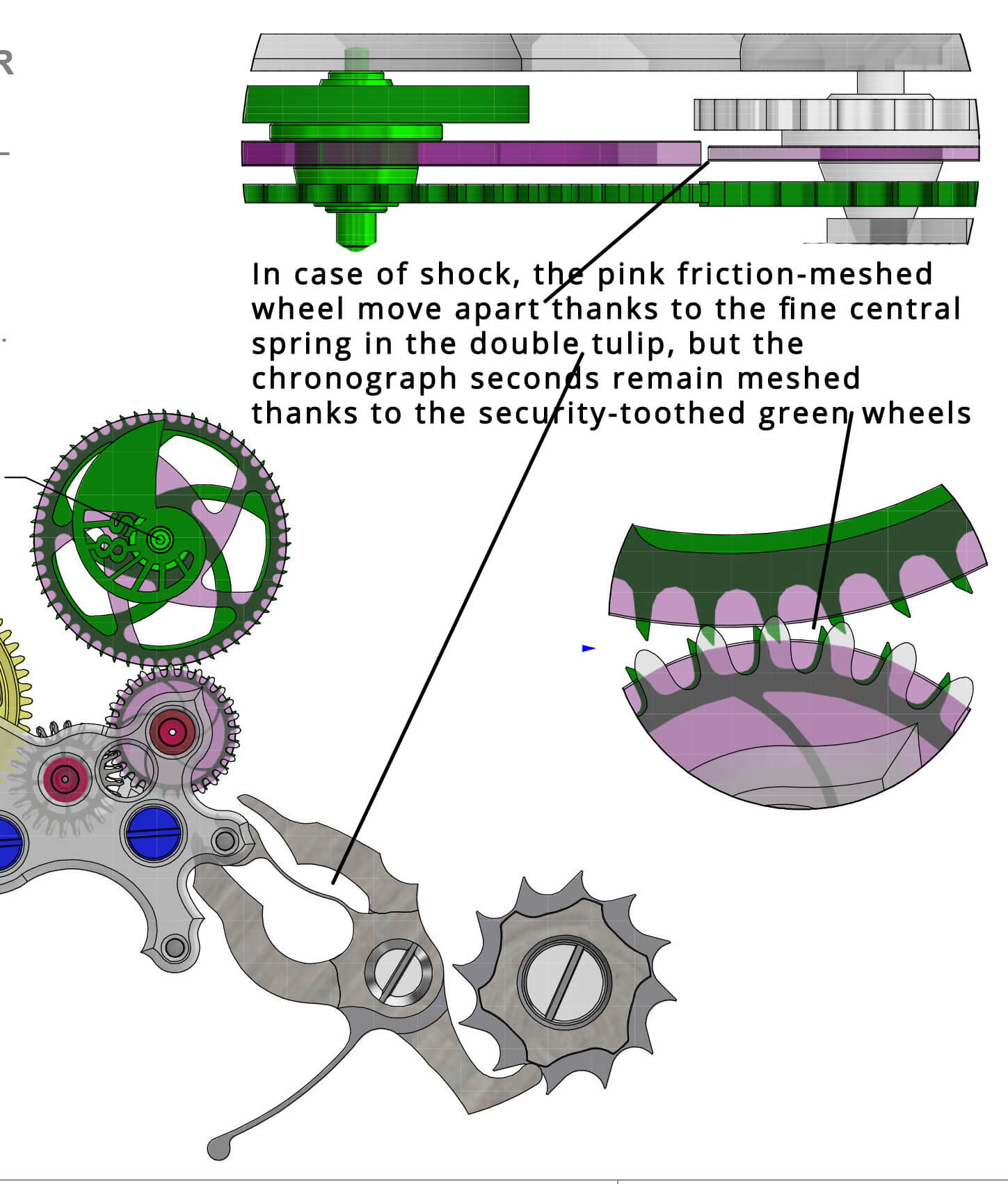

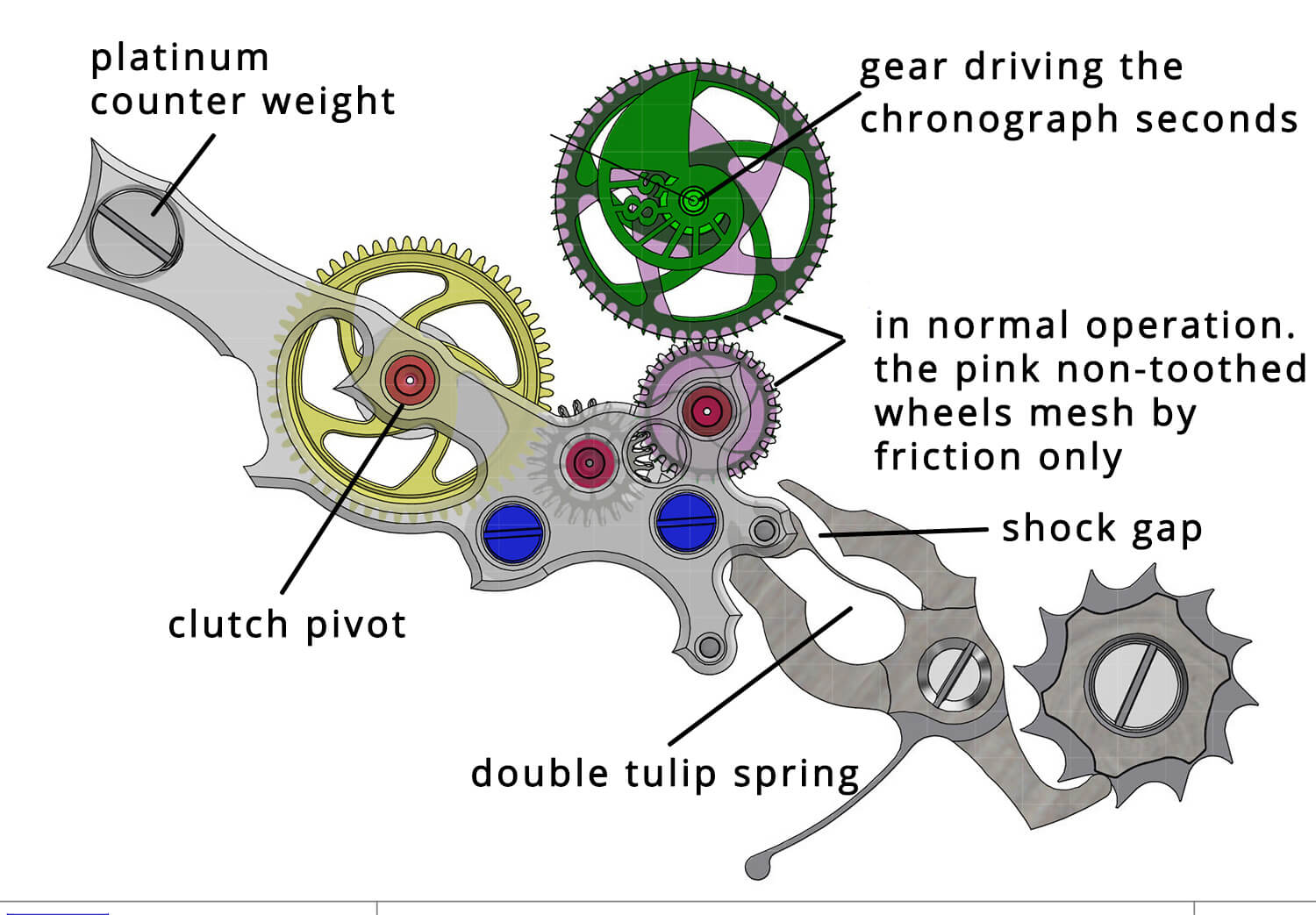

This new AgenClutch engages the chronograph mechanism by engaging two tooth-free wheels as in a traditional vertical clutch. But in cases of shock, a double tulip spring allows the two wheels to safely move apart but stay engaged thanks to toothed gearing like a traditional horizontal clutch.

The AgenClutch takes shocks in stride without losing timing information and with little risk of jamming

Unlike a traditional horizontal clutch, however, the teeth are very fine, which ensures that very little timing information − a maximum 0.33 of a second − is lost during the shock. There is no discernible vibration of the hands and the teeth do not jam when engaging.

May the force be with you

The AgenClutch has another significant advantage over traditional horizontal clutches: pressure, or to be more accurate, it requires little pressure to activate. To minimize the risks of the toothed gearing bouncing apart during shocks and so losing timing information and risk jamming, the gears are held together by relatively strong springs.

The force of these spring needs to be overcome when engaging and disengaging the chronograph by the applying force on the pushers: the force to overpower the clutch spring dictates the minimum force required on the pusher.

Because the AgenClutch has built-in flexibility to compensate for shocks, little timing information is lost during shocks and the fine teeth do not jam; strong springs are not required to hold the wheels of the clutch together.

This means that the force of the chronograph pushers can be selected at will and be tailored for different cases and models: a large sports watch with large pushers might feel best when activated by a relatively strong force on its pushers, while a dress watch-sized chronograph might have small pushers requiring much less force.

The AgenClutch pivots, while a platinum counterweight ensures that it is in perfect equilibrium.

The AgenClutch features the best of both horizontal and vertical chronograph clutches with none of the drawbacks

Swiss Army knife technology inside

The surfaces of the two clutch wheels have to have optimal friction so they neither slip nor stick, and much research and development went into learning what worked best. The answer to Switzerland’s latest world-class engineering invention lay in another more than a century old: the Swiss Army knife.

Those familiar with the ubiquitous Swiss Army knife may know that models are often outfitted with a file, and this file is created by the application of a special coating to a flat steel blade. Agenhor contacted Swiss Army knife manufacturer Wenger, which was bought in 2005 by the other major manufacturer of the knives, Victorinox, to learn how they made their files. Wiederrecht and his team used that information to develop a nickel coating with three microns of diamond dust for the surfaces of the chronograph clutch wheels.

Rotating seconds’ cam = constant power

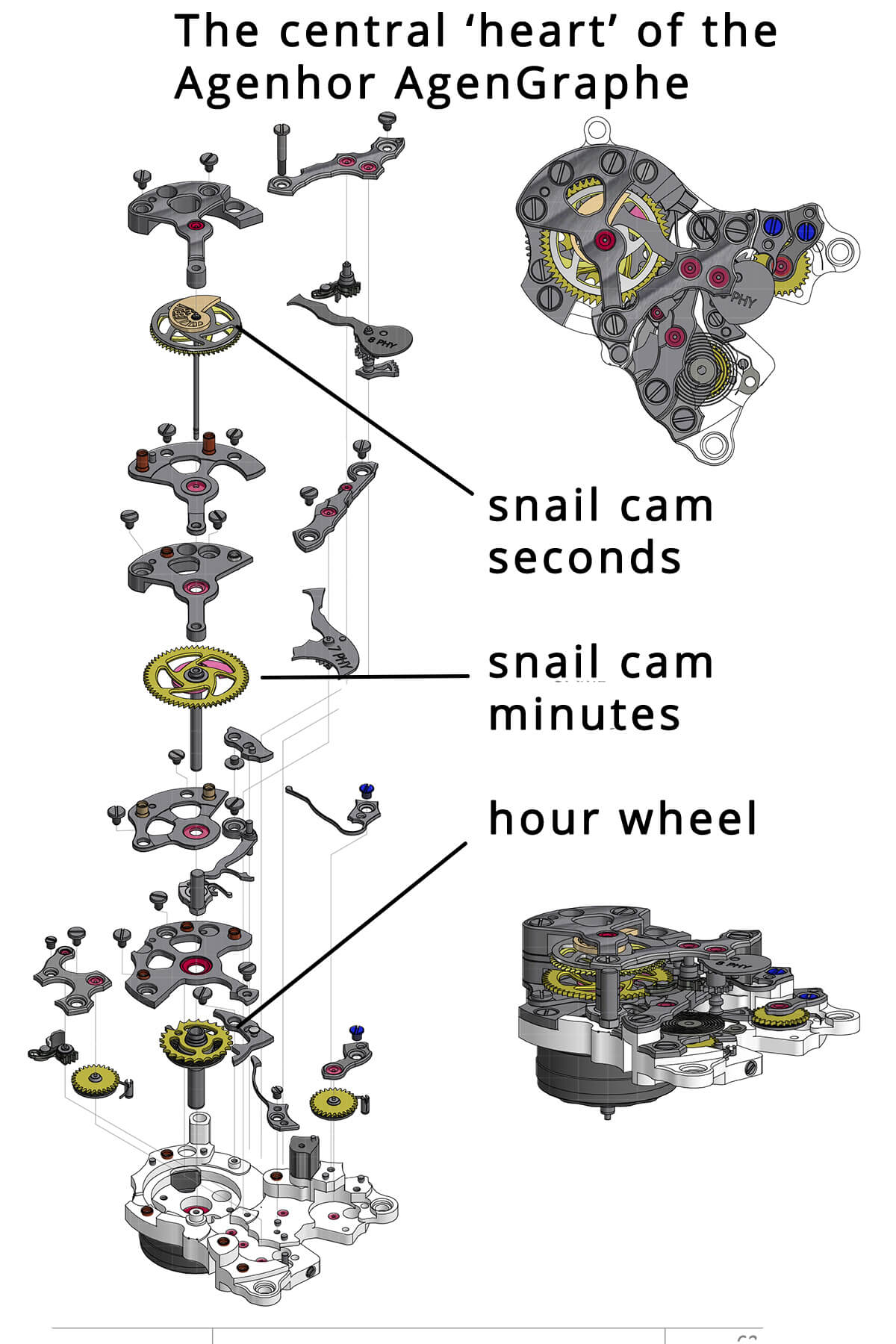

When engaged, the Agenhor chronograph mechanism is controlled by a series of two snail cams, one each for the seconds and minutes, and a wheel for the hours. Only the seconds’ snail cam is driven and it makes a full rotation every 60 seconds, tripping the minute cam and causing the minute hand to jump one full minute. Every 60 minutes the minute cam makes a full rotation, and when it does it causes the hour wheel to advance and jump one hour.

Exploded view of the AgenGraphe chronograph module

Agenhor experimented with more than 50 different cam profiles to arrive at the perfect angles for smooth and trouble-free operation throughout 360 degrees.

Because the second cam is rotating constantly when the chronograph is engaged, charging the minute and hour cams constantly rather than in one or two seconds as a traditional chronograph would, and each of the cams are driven off each other, the force required by the chronograph in operation is constant (unlike chronographs with horizontal clutches). There are no widely varying loads causing fluctuating amplitude on the balance wheel so the timing and precision of the movement is much more predicable.

No violent reset backlash

When the AgenGraphe chronograph is stopped to read elapsed time, a brake is applied to the chronograph seconds’ wheel, holding it in place. Simultaneously, the clutch is disengaged.

When the reset pusher is activated, it simply releases the brake on the wheel, and the spring tension on the arm tracking the cam gently (in comparison to a traditional chronograph reset) reverses it back to its neutral zero position.

There is no violent backlash on the chronograph second hand, so no increased wear or risk of damage.

AgenGraphe chronograph movement by Agenhor

And there’s more: patented regulator and long power reserve

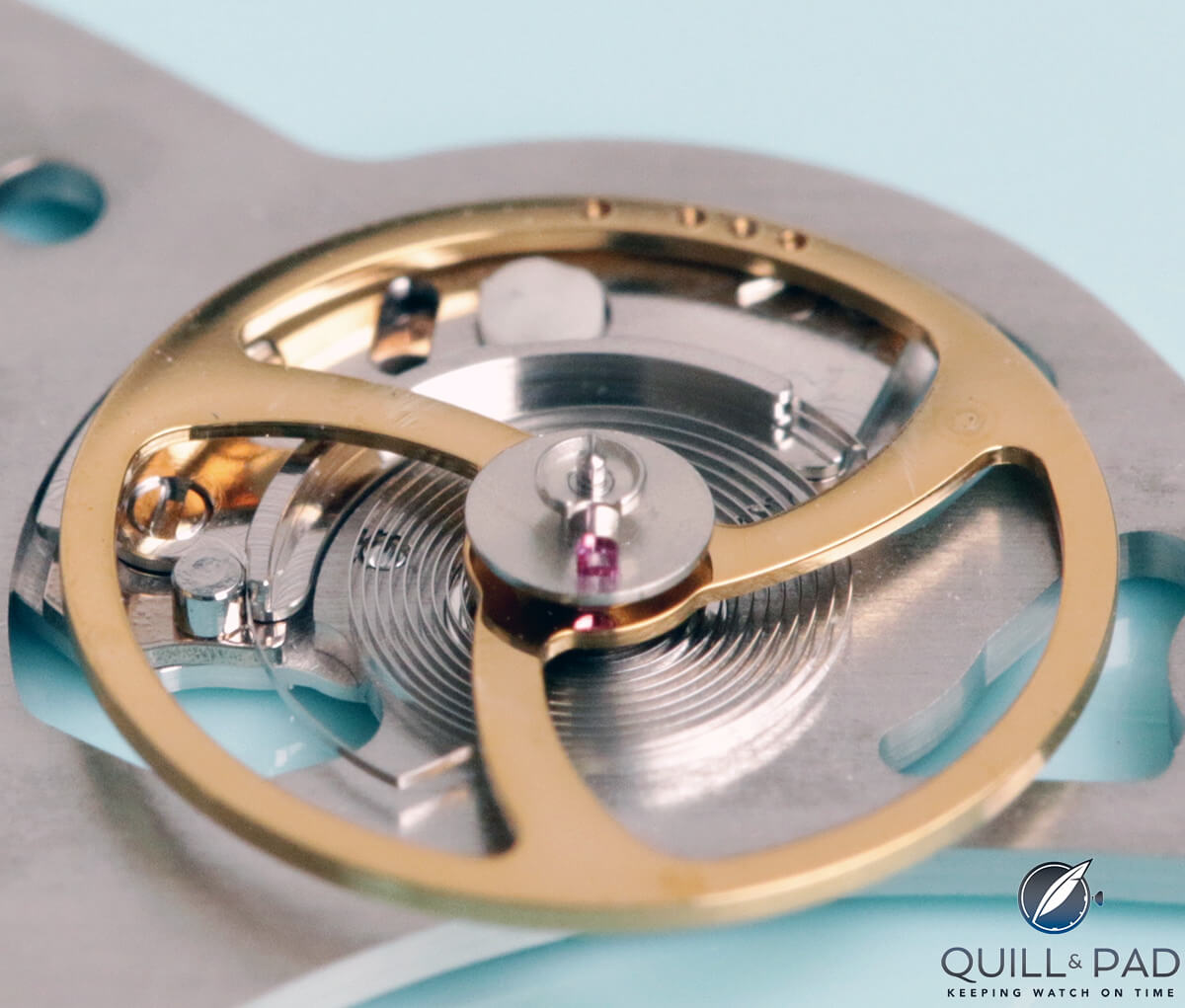

The regulator of the Caliber AGH-6361 automatic chronograph features Agenhor’s patented AgenPit regulator, which does not require a hairspring fixation stud and is very easy to regulate.

Patented Agenhor AgenPit regulator

Patented Agenhor AgenPit regulator

The Agenhor chronograph also benefits from a long 60-hour power reserve and will work for the full 60+ hours even if the chronograph is constantly operating for all of that time.

Is there anything not to like?

After 200 years of the industry tinkering with chronographs, Agenhor has completely reinvented the mechanism and in the process made all existing chronographs technically obsolete.

The bad news: the drawback of this revolutionary chronograph movement is . . .

The only drawback to the AGH-6361 automatic chronograph is that Agenhor develops and sells movements, not watches, so you will have to wait for brands to start incorporating the movement into their own timepieces.

The first two brands using the Agengraphe are Luckily, though, you will not have long to wait as the Agenhor AgenGraphe movement was launched in 2017 by two brands: Fabergé with the Visionnaire Chronograph and Singer Reimaged with Track 1.

Quick Facts AgenGraphe Caliber AGH-6361 automatic chronograph movement

Functions: hours and minutes displayed by disks around dial perimeter; chronograph with elapsed hours, minutes, and seconds displayed on inner dial

Dimensions: 34 x 7.17 mm (with rotor)

Number of components: 477

Frequency: 3 Hertz/21,600 vph, patented regulator

Winding system: automatic with dial-side rotor, two mainspring barrels

Power reserve: 60+ optimal hours from two spring barrels

* This article was first published on February 20, 2017 at The AgenGraphe By Agenhor: The Most Significant Chronograph Since . . . Since The Invention Of The Chronograph (With Videos).

Leave a Reply

Want to join the discussion?Feel free to contribute!