The crystalline sound that glass makes when rubbed or tapped can be one of the most hauntingly beautiful aural experiences you are likely to ever hear.

Most people think of glass as a brittle, transparent material that is used mainly for its optical properties or to hold a cold drink. While this is generally accurate, glass has many more functions, one of which is as an acoustic material.

Glass has been used for centuries to create musical instruments, starting with the glass harp (aka water glasses) in Persia in the fourteenth century and the glass harmonica (also known as a glass armonica) in the eighteenth century (an invention attributed to Benjamin Franklin), all the way to the twentieth century with the glass marimba and the cristal baschet invented in 1952. There are at least ten different types of glass musical instruments in existence using the glass in different ways to create sounds.

Whether the vibrations are created by friction, striking, or combustion (yes, fire in an instrument called the pyrophone, and it’s eerily cool), glass has a rich history with music spanning centuries, continuing to this day. Glass, however, suffers from material consistency issues when it comes to producing clean, precise notes – hence the haunting sound.

Lead glass, also known as “crystal” is much more consistent than basic silicate glass, but it still may contain impurities. And more importantly the manufacturing process might not create a solid object with perfectly maintained thicknesses and dimensions. That is because glass, a non-crystalline amorphous solid, exhibits a glass transition phase (turning from hard and brittle to viscous and malleable) with the addition of heat. This means that while glass is cooling down after being in that phase, it can still flow as a semi-liquid, causing dimensions to change while the material transitions to become a solid.

If something better was desired, something that would ring truer, actual crystal is the next step up from glass.

Elements such as quartz and sapphire form a single crystal across the entire structure, and with careful processing a very resonant shape can be created from a completely homogenous solid. If the solid is absolutely consistent, making for a perfect crystal, vibrations (and therefore sound waves) can propagate most efficiently through the material and create a clear and lasting tone.

Why would you need to know all of that detail?

Chopard L.U.C Full Strike minute repeater

Because you are ready to be blown away by the incredible Chopard L.U.C Full Strike, the brand’s first minute repeater featuring a pair of sapphire crystal gongs! Machined from a solid block of sapphire, they are one piece with the front sapphire crystal. Holy smokes!

Let’s just dive right in.

Sapphire, the answer all along

The L.U.C Full Strike is the result of more than six years and 17,000 hours of dedication, research, and development. And before I go any further, it is, in my opinion, one of the best-sounding minute repeaters on the market today. Now that I’ve said something people can argue about, the facts are begging to be shared.

The solution to clarity, volume, and resonance in minute repeater gongs, at least for Chopard, was to switch to sapphire. Creating gongs out of steel or some other metal is always less than optimal as the internal structure of the metal cannot be controlled or verified, so imperfect sound propagation will always be the result. Making the gongs from a crystal like sapphire is the only way to know with complete certainty that the gong will be perfectly free of internal defects that might deaden, muffle, slow, or shift the tone coming from the gong when struck.

Chopard L.U.C Full Strike minute repeater

But that wasn’t enough: because getting the sound from the gongs and out of the case so it can be heard is usually the second major hurdle when creating a chiming watch.

Any break in material or meeting of two dissimilar materials will cause a reduction in the sound wave and a less powerful and resonant tone. Many other brands have poured tons of research and manpower into this problem and come up with a variety of answers.

Chopard L.U.C Full Strike minute repeater

Chopard skipped right over the problem and made the gongs a part of the crystal so that they are in direct contact to the air between your ears and the gongs.

Well, technically exposed to the air; the gongs are underneath the crystal but the gongs and crystal are one single piece. As I stated before, the gongs and crystal are machined from a single block of sapphire, the front crystal and two semi-circular gongs descending from the inside surface. This effectively turns the crystal into a large amplifier, allowing the vibrations to move straight from the gong to the front crystal with no interruption and then to transfer into the air and straight to your ears.

Chopard L.U.C Full Strike minute repeater

This is the most direct path possible without moving the gongs outside of the case on the front of the watch (not advisable). The only ways I can imagine to make it more resonant is to modify the geometry of the gong/crystal based on wave propagation to direct the sound wave more accurately or figure out a way to isolate the crystal itself (since it is press-fit into the case via a crystal gasket) to allow even more vibration.

But at that point, any increases in sound, tone, and resonance might be rather minor compared to the difference already gained with the current construction technique.

Challenges and solutions

Speaking of the construction technique, developing the process of machining the gongs and crystal from a solid piece took three years of research in order to create a workable solution.

Chopard L.U.C Full Strike minute repeater

Even then, machining one crystal takes around two weeks. That is a rather long time, and it would be totally worth it if none of the parts ever broke. But that isn’t how making things works (trust me, I know); during the machining and finishing process there is a 33 percent failure rate, meaning one in three crystals will break before it can be completed. I can only imagine the frustration of coming in after 12 days of machining to see that a gong cracked and the entire piece is ruined.

Once the crystals were successfully made during the prototyping phase, they were evaluated in collaboration with the University of Lyon to see if they achieved the desired acoustical result. This is where a large part of time in development was spent, going back and forth changing dimensions, shapes, and retesting the next pieces after assuredly one or two also broke during machining.

Chopard L.U.C Full Strike minute repeater

Simply getting parts to evaluate is tough, making development a long and tedious process. But based on the sound the Full Strike makes, it was totally worth it.

Once made, the gongs are quite durable as a result of being solid sapphire, during testing they found that the gongs performed beautifully and without fail after 1.5 million strikes of the steel hammers. That is a little over 88,000 cycles of a full 12:59 chime for the (higher tones of the) minute gong, and 100,000 cycles for the (lower tones of the) hour gong, a considerable testing period for any product let alone an extremely high-end minute repeater. Though putting in all that work to get a clear, crisp, and vibrant sound would have been pointless if other aspects of the movement weren’t addressed too.

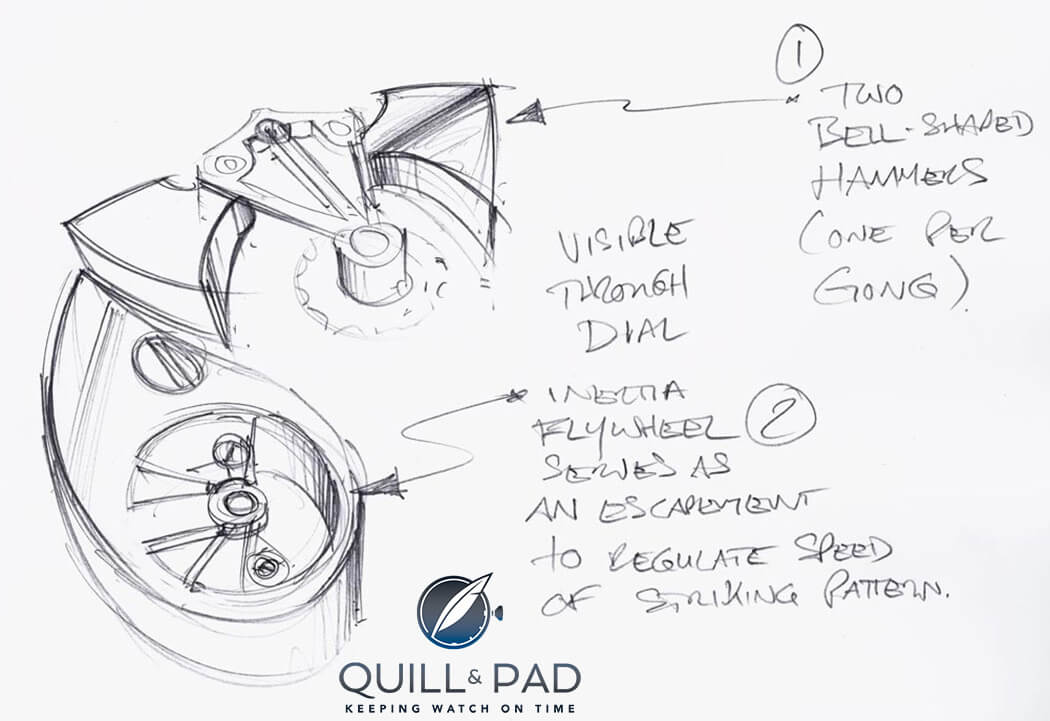

Sketches of the Chopard L.U.C Full Strike minute repeater

The hammers were designed to allow watchmakers to individually adjust the striking force, which makes it possible to precisely tune the intensity of the strike.

And, finally, after the tremendous work on the gongs that resulted in terrific sound (and a patent), the watchmakers and engineers tackled other issues common to all minute repeaters.

First up were silences and rhythm. The majority of minute repeaters have periods of silence (sometimes quite long silences) between chiming the hours and the minutes when there are less than three quarter hours to strike. In the first 14 minutes after each hour (no quarters at all), the gap can be very notable. To combat this, Chopard designed the repeater racks to drive each other instead of all being driven off of a central train.

Caliber 08.01-L of the Chopard L.U.C Full Strike minute repeater

This means that no matter what each rack is set to play, the chimes will start immediately after each other as each one is activated by the completion of the one before it. This is simple enough in theory, but very difficult to implement.

The next strep was to quiet any superfluous noise caused by the operation of the mechanism itself. Other brands have tackled this issue with varying success; Chopard overhauled the design of the governor system to eliminate any humming from the high-speed rotation, and based on the new method for driving the chime, eliminated any mechanical ticking in the system as the racks reset.

These sounds have always seemed minimal to me, but when they are gone the sound of the chime is just that much clearer.

Safety, too

Given the quality of the chime and work done in making the Full Strike sound as great as possible, the next steps for Chopard were to protect the mechanism so that it wouldn’t get broken through improper use. This meant that security mechanisms were implemented into the movement.

It all began with changing the way the repeater mechanism was powered. Instead of a slider that charged a small spring, which is the conventional route, the repeater mechanism is entirely powered from its own mainspring. A second spring barrel was added that is wound using the crown with enough reserve to power a full chime 12 times (16 seconds of chime at 12:59). This power reserve is indicated, along with the regular power reserve, by a double power reserve indicator featuring two coaxial hands, gold for the regular going train power and blue for the minute repeater mechanism.

Chopard L.U.C Full Strike minute repeater

The power reserve also serves another function: to limit and deactivate the minute repeater mechanism should the power fall too low to complete the full sequence of chimes. A partially toothed wheel combined with the reserve indicator blocks the mechanism from operating at an insufficient charge, lest the mechanism get stuck in the middle of the chime, where the components would be at a much higher risk for breakage.

Another addition was tasked with maximizing the repeater power reserve and preventing breakage by keeping the regulator from rotating until the mechanism had coupled with the time racks. This reduced the time the mechanism draws from the power reserve and it also ensures that nothing is attempting to chime until everything is in its place.

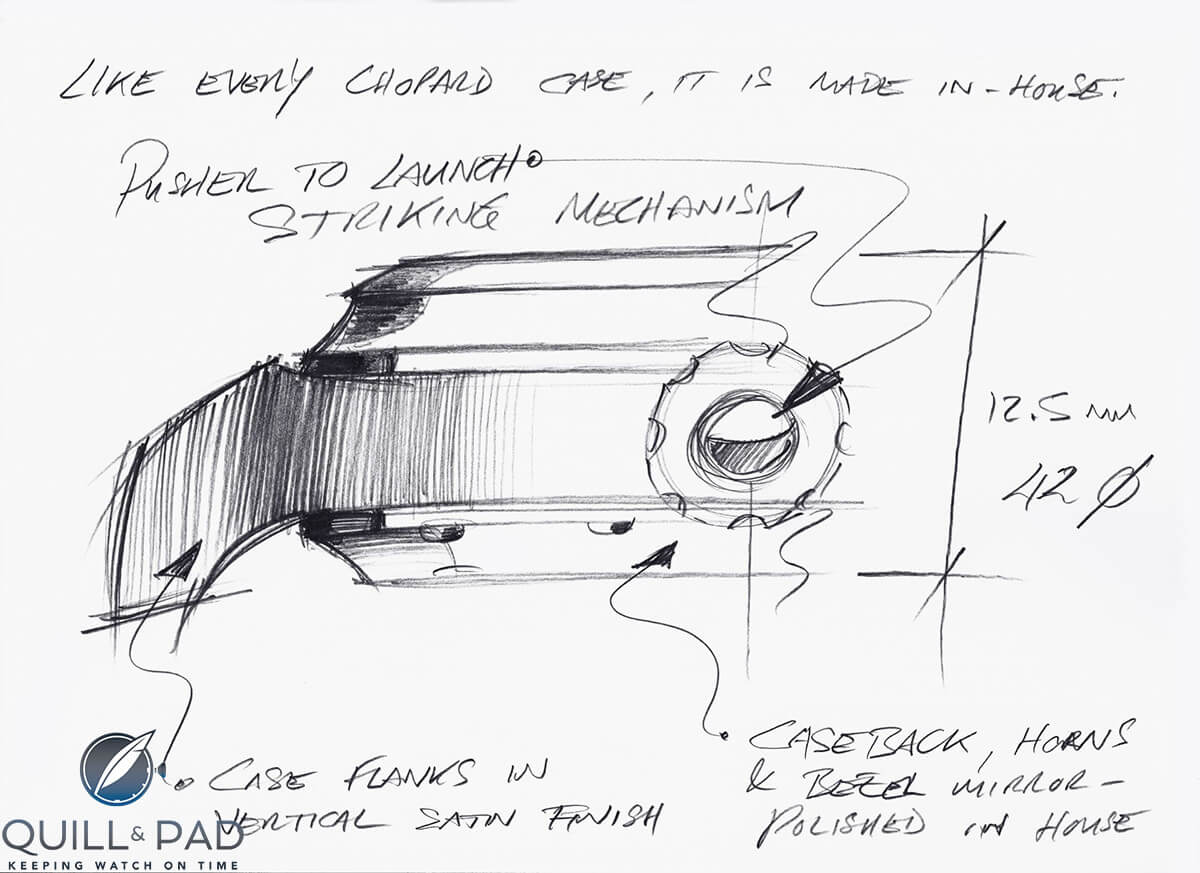

A sketch of the Chopard L.U.C Full Strike minute repeater case

Continuing with this protection, the crown becomes disconnected when the activator is pushed, making sure that no time adjustment would be possible during the chiming process. Furthermore, the activator can also only be pushed once before disconnecting, ensuring that no additional presses can put stress on the components and break the delicate mechanism.

And, of course, protecting the mechanism from breakage leads to the desire to protect the chime from sounding poorly as it operates. For this reason, the gathering racks don’t interact directly with the hammers, but instead mesh with a ratchet wheel that then activates the hammers. The ratchet wheels have teeth around a circumference, instead of along the side of a rack, which when combined with the indirect drive of the hammers from the racks, allows for a smooth, consistent, and equal striking speed and force on the gongs, further increasing the quality of the sound.

The efforts put into protecting the mechanism that was developed over six years will definitely not be taken for granted.

An exploded view of the movement of the Chopard L.U.C Full Strike minute repeater

If the story ended there, it would already be worthy of praise, but the L.U.C Full Strike also bears the Geneva Seal, requiring every single surface of every single part was purposefully finished and/or decorated to a higher standard. Given the sheer size of the some of the smallest parts in the repeater mechanism, this fact increases the workload by likely more than 100 hours, a substantial effort after the difficulty in making the piece in the first place.

But that effort is part and parcel of Chopard’s devotion to the Full Strike.

And it’s also worth highlighting that the gold used for the case is certified Fairmined and the leather for the straps is plant-dyed, CITES-certified alligator. It shows that there is no aspect of the timepiece that has been overlooked, and when possible, improved to be in line with the corporate ethics and values.

Chopard L.U.C Full Strike minute repeater

The L.U.C Full Strike is amazing when simply considered on its own, but when considered in context new layers of value and importance appear. A C.O.S.C.- and Geneva Seal-certified minute repeater with sapphire gongs placed in an ethically sourced gold case with an ethically sourced leather strap coming from a historic jeweler instead of a young, hip, environmentally aimed brand is a huge deal.

At least it is a huge deal to me as it mixes the best parts of haute horology, cutting-edge manufacturing, and corporate responsibility.

What’s not to love?

Oh yeah, and that beautiful, crystal clear sound.

If it must be, then we must see . . . the breakdown!

- Wowza Factor * 9.88 That sound causes you to pause, and then gasp, and then wordlessly mouth the word, “Wow!”

- Late Night Lust Appeal * 98.76 » 968.504m/s2 The midnight hours are extra quiet so the sound of the Full Strike carries you into darkened bliss.

- M.G.R. * 70.4 Extremely strong M.G.R. for the L.U.C Full Strike thanks to all the improvements over traditional minute repeaters and the visible awesomeness of the sapphire gongs!

- Added-Functionitis * Severe Minute repeater and two power reserve indicators stand for one healthy dose of added functions. You’ll definitely need emergency strength Gotta-HAVE-That cream for the sonorous swelling inside!

- Ouch Outline * 12.35 Hot coffee spilled in your lap while driving down the freeway! Hasn’t happened to me, but to people I know (including our esteemed editor-in-chief). And it isn’t pretty. But, and this is a hesitant but, if it meant getting this watch to grace my wrist, I just might set that coffee on my steering wheel and drive off into the sunset!

- Mermaid Moment * Just One Chime! Seriously, the sound is so clean and pure you’ll wonder why you haven’t booked a chapel yet!

- Awesome Total * 861.5 Multiply the number of pieces (20) with the diameter of the case (42.5) and then add the rather low height (11.5) for an auditorastic awesome total!

For more information, please visit www.chopard.com/intl/diary/l-u-c-full-strike-crystal-clear-sound.

Quick Facts Chopard L.U.C Full Strike

Case: 42.5 x 11.5 mm, 18-karat Fairmined pink gold

Movement: manual winding Caliber 08.01-L with 60-hour power reserve and sapphire crystal gongs; C.O.S.C.; Geneva Seal

Functions: hours, minutes, seconds; minute repeater, power reserve, minute repeater power reserve

Limitation: 20 pieces

Price: 245,000 Swiss francs

* This article was first published on September 17, 2017 at Chopard L.U.C Full Strike Minute Repeater With Crystal Power! Plus Video: Listen For Yourself.

You may also enjoy:

Chopard L.U.C Flying T Twin: Technically Superb, Ethically Crafted, And Simply Gorgeous

Chopard L.U.C XPS And Tourbillon QF In Fairmined Gold: Making A Sustainable Difference

Leave a Reply

Want to join the discussion?Feel free to contribute!