Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronometer (Part 1 of 3)

by Ian Skellern

Introduction

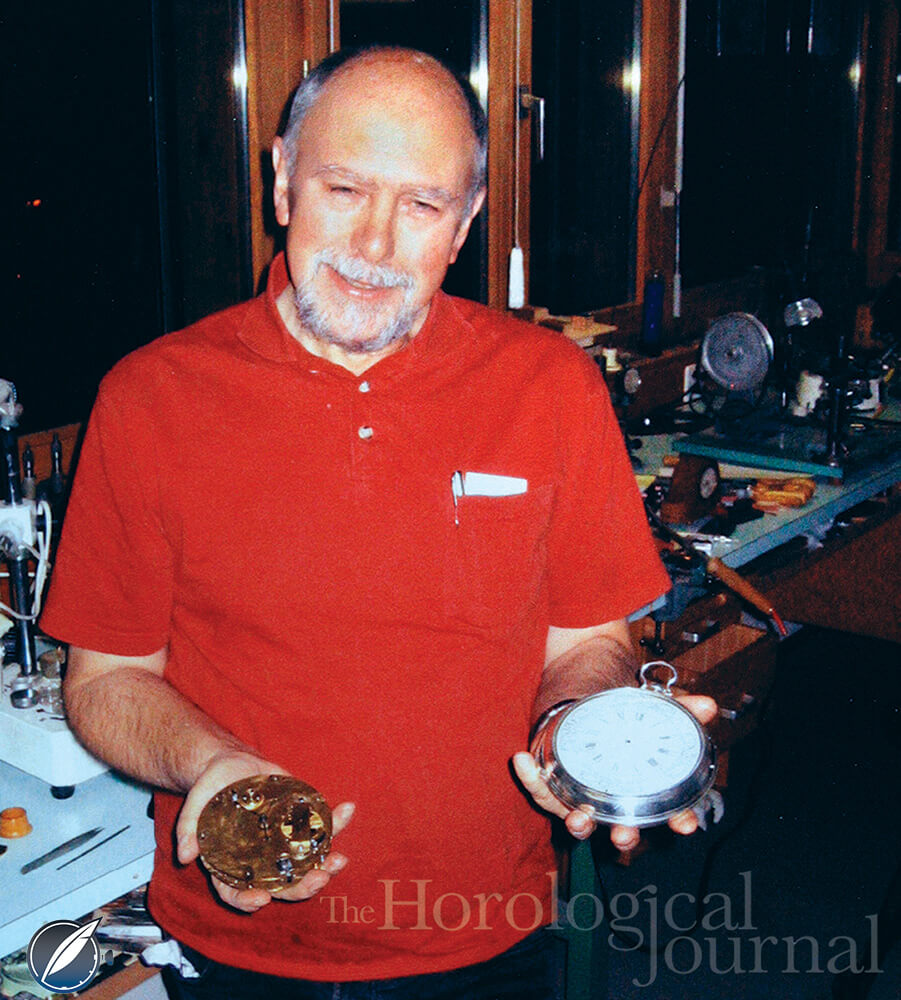

I first had came across the name Derek Pratt in 2004 while visiting Peter Baumberger, then owner of Urban Jürgensen & Sønner, who showed me two of the most beautiful pocket watches I had (and have) ever had the pleasure of seeing. Baumberger explained that after he had resurrected Urban Jürgensen, he started with working with Pratt, who became the brand’s consultant and chief watchmaker.

While generally working outside the public eye, Pratt, who died in 2009, was a true legend among watchmakers and ranked alongside George Daniels, Philippe Dufour, and Daniel Roth as one of the very best.

As if it needed proving, in 1999 Pratt was awarded the prestigious Prix Gaïa (the Nobel prize of watchmaking) for merit in the developments in the field of artisanal creation in watchmaking.

In 1997, Pratt decided to make his own copy of John Harrison’s H4, the watch that won the British Admiralty Longitude Prize. Harrison’s H4, completed in 1761, was so accurate on a test voyage to Jamaica and back that the examiners deemed it a fluke and asked for a second trial voyage. The H4 also passed this with flying colors. The historical timepiece now belongs to the British National Maritime Museum.

Pratt spent years researching the watch to learn how it was made and what the techniques and materials Harrison was likely to have used. But is wasn’t just the mechanics and watchmaking Pratt wanted to replicate authentically, but also the piercing and engraving of the silver cases (there were two) and dial. And, naturally, its legendary diamond pallets would pose quite a challenge.

Pratt commissioned master craftsmen for the case and dial and began work on the movement, making of many of the components including the frame, plates, balance, fusée and chain, barrels, mainspring, and the wheel train.

John Harrison is quoted as saying of H4, “ . . . I think I may make bold to say that there is neither any other mechanical nor mathematical thing in the world that is more beautiful or curious in texture than this my watch or timekeeper for the Longitude . . . ” He also said, “I hereby thank almighty God that I have lived so long as in some measure to complete it.”

Unfortunately, Pratt did not have the same amount of time left in his life to compete his copy of H4, however before his death he asked the London-based Charles Frodsham & Company to complete the project, which it did. However, it took Frodsham a full four years.

I became interested in Pratt’s H4 after seeing a rough-cut film of the project at the 150th anniversary celebration event of the British Horological Institute in June 2008.

You can buy a DVD of that film at www.bdvideos.co.uk (all profits go to the charity Prostate Cancer UK in honor of Pratt’s memory).

Pratt was also working on a wristwatch featuring a remontoir d’égalité, flying mainspring barrels, and dead seconds. While it is deliberately unassuming on the dial side, the movement is simply superb. This project has been continued and I hope to post more on that soon.

For a fuller biography, please see The Life And Times Of Legendary Independent Watchmaker Derek Pratt.

Below is the first part of a three-part series about the making of Derek Pratt’s H4 reconstruction by Roger Stevenson, the chief watchmaker at Frodshams. This article was first published in the The Horological Journal (HJ) in February 2015 and we thank them for permission to republish on Quill & Pad.

You will find Part 2 at Making Diamond The Diamond Pallets For Derek Pratt’s Reconstruction Of John Harrison’s H4, The World’s First Precision Marine Chronometer (Part 2 of 3) and part 3 at Making The Escapement, Remontoir, And Timing For Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronometer (Part 3 of 3).

Reconstruction of John Harrison’s H4 by Derek Pratt, which was finished by Frodshams (image courtesy British Horological Journal)

Movement of the reconstruction of John Harrison’s H4 by Derek Pratt, which was finished by Frodshams (image courtesy British Horological Journal)

Part 1: Charles Frodsham & Co on the Power Train and Jeweling

by Roger Stevenson FBHI

From an early age, Derek Pratt had a fascination with all things mechanical. Around 1947, when he was still a boy, he saw Harrison’s H2 displayed at the London Science Museum. Later, he was given a copy of Rupert T. Gould’s The Marine Chronometer, its History and Development. He was totally absorbed by Gould’s account of the struggle towards precision timekeeping. Following his intense interest in horology, he went on to attend the National School of Horology in combination with an apprenticeship with S. Smith & Sons.

Derek made a number of exceptional pocket watches in the 1980s and 1990s, all incorporating his own innovative ideas. Around 1997 he returned to his interest in Harrison and decided to make his own copy of H4. This was a major undertaking that was to occupy the remaining years of his life. Derek wanted to make the watch as a tribute to John Harrison and he also wanted to use the project as an in-depth study of the timekeeper. Of all Harrison’s timekeepers, H4 was the one Derek wanted to make; after all, it had won the Longitude Prize.

H4 incorporated the technical advances Harrison had used in his earlier timekeepers: temperature compensation, a remontoir and maintaining power but, crucially, it was smaller and had a balance running at 18,000 beats per hour. Harrison’s watch, made for him by John Jefferys around 1753, also had these features but without the remontoir. It must have performed well and encouraged Harrison to refine the design and add a remontoir. The modified verge escapement of the Jefferys watch and of H4 enabled the balance to run at a much higher amplitude than the traditional verge. This, coupled with the light but large diameter of the balance, gave the watch a high stored energy and made it far less prone to disturbances than its seconds-beating predecessors, H1, H2, and H3.

The early stages of the project are recorded on film by Barbara Darby, with Derek commentating on his interest in Harrison and showing some of the work in progress. This film was introduced by Derek at the St. Roche lecture at West Dean in 2008 and was shown again at the British Horological Institute’s BHI 150 weekend in 2008 two days later with an introduction by Jonathan Betts. Derek had identified four areas in the making of H4 that would be particularly challenging: these were the silver pair case, the dial, the pierced and engraved decoration, and the diamond pallets. For the first three, Derek needed outside help, and because of his enthusiasm for the project he inspired other highly skilled craftsmen to assist.

Finding the right people and organizing the work to be done was a significant task. After working with a number of craftsmen, he commissioned Martin Matthews to make the case, Jos Houbraken from the Netherlands to make the dial, and Charles Scarr to pierce and engrave the decorative work. It was fitting that all three craftsmen were at the St. Roche lecture, where their superb work could be both seen and celebrated. This part of the project is recorded in two BHI publications.

At Frodshams we had a long-standing friendship with Derek, who had been very helpful to us and was a regular visitor to the workshops. Derek knew that he would not be able to complete his H4 and he asked us to take on the project. It was a privilege to be asked to complete the watch, but we all miss Derek.

Derek Pratt holding his H4 in his workshop in Switzerland in 2005 (photo courtesy British Horological Journal)

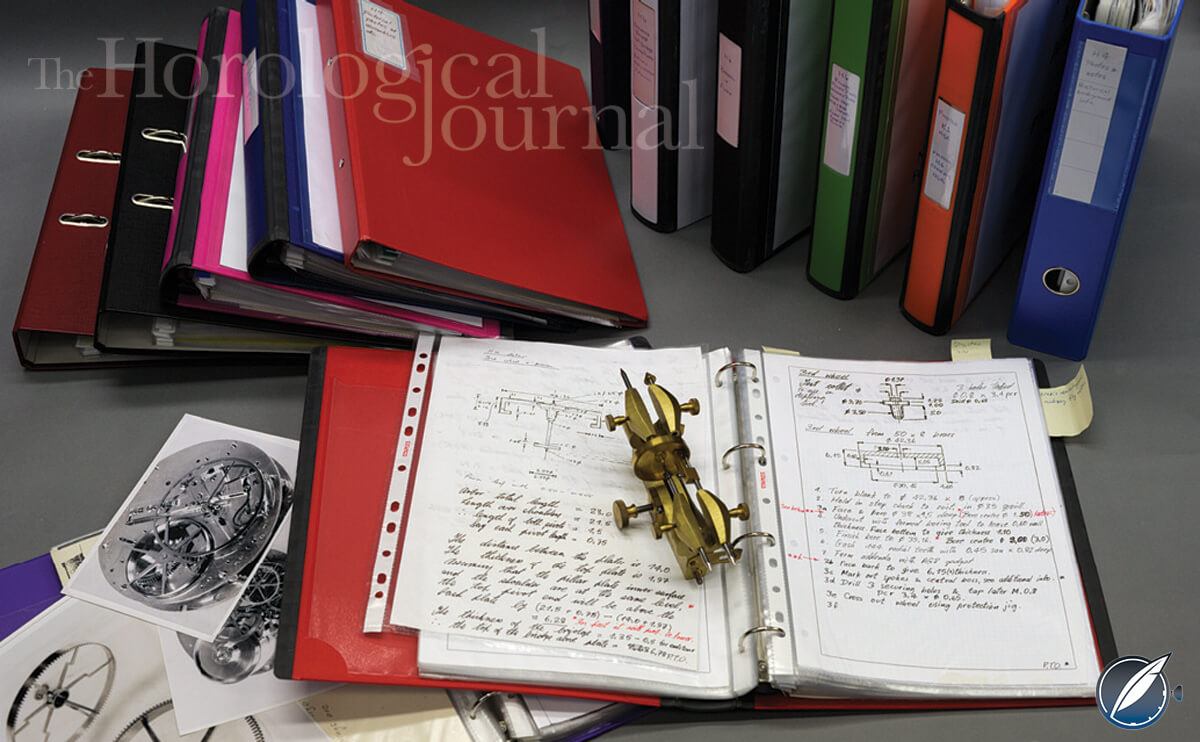

During his research Derek had gathered every scrap of information he could in order to establish the dimensions of H4. Anthony Randall had already made a carriage clock with a reconstruction of H4’s gear train, remontoir, and escapement and had accumulated information from studying H4, K1, and H5. Anthony generously passed this on to Derek and later to us at Frodshams. Gradually, Derek was able to make drawings of the individual parts and work out the co-ordinates for the plates.

Derek Pratt’s H4 files and drawings (photo courtesy British Horological Journal)

By 2008 Derek had made the movement plates, the fusée, the inner barrel that contains the mainspring, the center wheel, third wheel, most of the pinions, and had started on the motion work. In the summer of 2009 Philip Whyte and I met with him in Switzerland to learn from Derek what stage he had reached and to start taking on the project. It must have been a painful process for Derek to be handing over the work that had consumed so much of his time and effort. These times with Derek and his wife, Jenny, were very precious and although Derek was seriously ill he was still such good company and full of interesting stories.

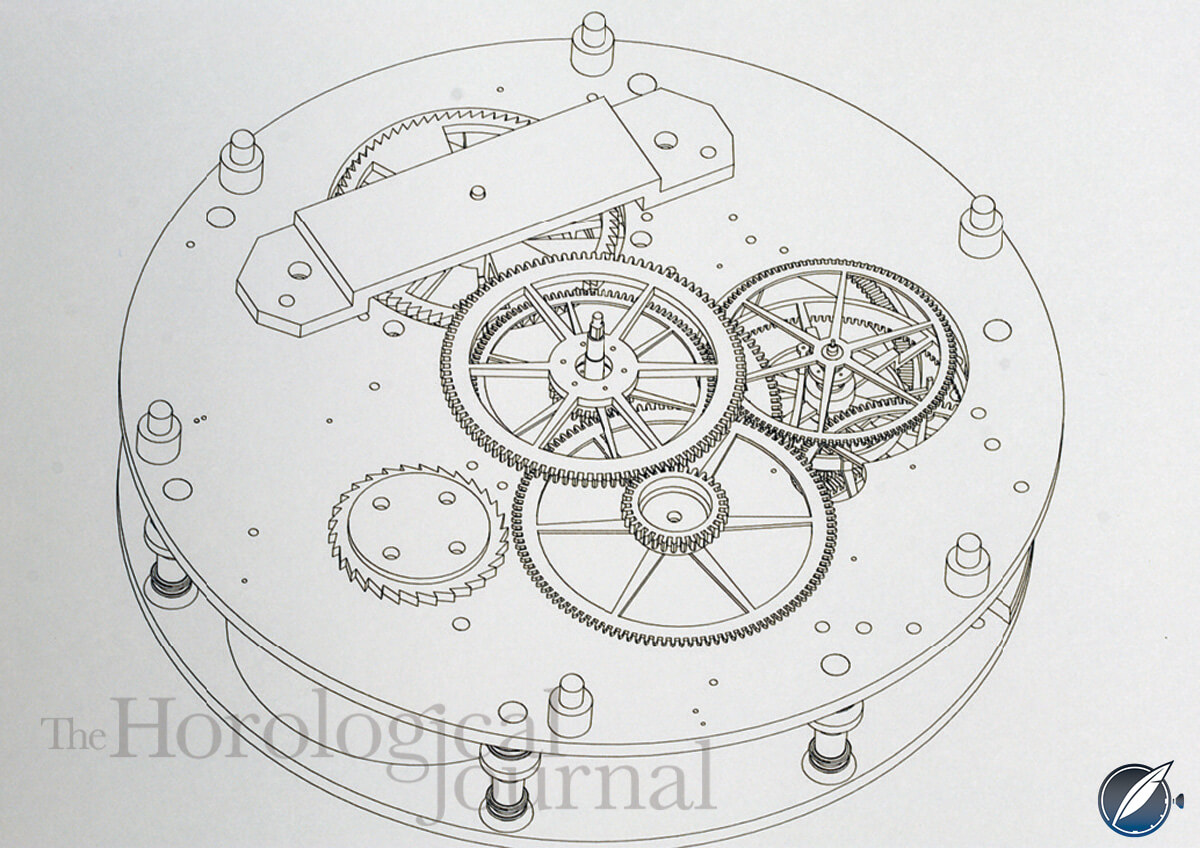

Derek gave us a summary of the work he had completed and what he saw as the next stages. With Derek’s notes and drawings and the dimensioned sketches from Anthony Randall we were able to start to build up a CAD model of the watch. This was felt necessary to establish the heights and clearances of the components. My colleague Martin Dorsch did most of this work. There are good photographs of H4 that were taken at the Chronometer Workshops, Herstmonceux when the watch was serviced there in the 1960s. Most of these photos were taken looking straight down on the components without many side views. The watch is 14 mm between the upper and lower plates and there is a lot of mechanism packed into this space, particularly around the escapement and remontoir.

CAD drawing of H4 (photo courtesy British Horological Journal)

Barrel, fusée, and maintaining work

Where to start? It seemed logical to begin with the barrel and fusée, then to work through the train to the escapement, then back to the remontoir and finally the motion work. This is roughly the order in which things were done. Derek had titled his drawing of the fusée arbor as “experimental” as the heights were difficult to determine. To quote Derek, “Some of the information available is sparse and therefore the best approach is to make something, always with the thought in mind that this might be the first attempt . . . one learns a great deal from having a metal component that one can fit in place.”

Starting the work

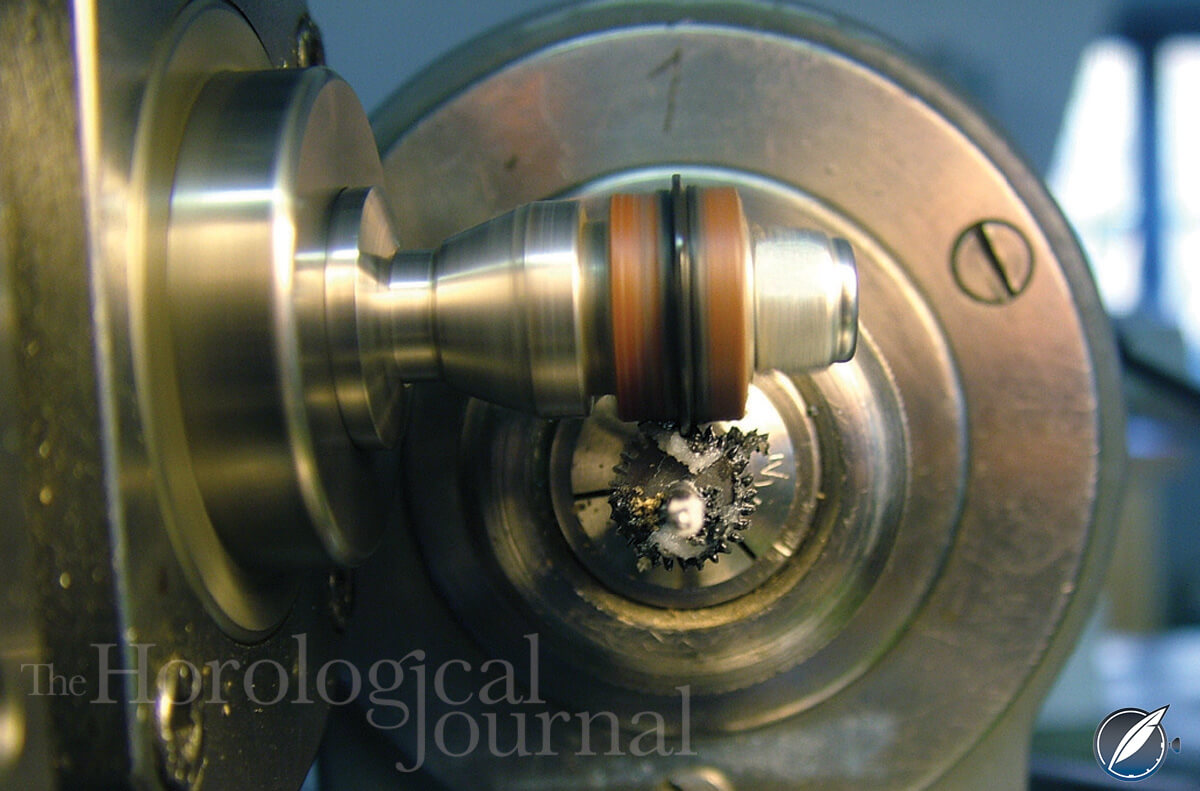

Turning the fusée arbor of Derek Pratt’s H4 reconstruction

The image above shows the fusée arbor being turned from a 30 mm silver steel bar on a Hardinge lathe. The fusée stop and the rest of the arbor are all in one; an unusually large part for H4! Once turned, the fusée stop was cut with a piercing saw and filed to shape.

Cutting the fusée stop of Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

The arbor was then hardened and tempered. Daniela Hofer made the outer barrel (the going barrel that carries the chain) and completed the inner barrel.

Filing the mainspring hooking in the inner barrel of Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

The maintaining spring is contained within the cone of the fusée. It is a complex arrangement of 15 parts including spring barrel and ratchet.

Part of the maintaining work viewed from the dial side (photo courtesy British Horological Journal)

Many of the parts are intricate and required careful hand-finishing, such as the two maintaining clicks and springs.

Maintaining clicks and springs of Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

The plates and train

As mentioned previously, Derek had cut the center wheel, the internally-cut third wheel, and some of the pinions blanks. The third wheel pinion needed to be turned to fit and then polished. The pinion leaves were polished using a lignum vitae lap charged with one micron aluminum oxide (diamantine) and the pinion faces using a tin polisher with the pinion mounted in a swing tool. The method was used for all pinion faces.

Lignum vitae lap polishing the third wheel pinion indexed in the lathe of Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

Pinion face polished in a swing tool for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

Derek had planted the barrel, fusée, and center wheel and spotted the positions for the remontoir locking wheel and fly using his Hauser jig borer.

Positions for the fourth wheel, fifth wheel (remontoir locking wheel), fly, remontoir detent, and balance center for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

The fourth wheel, escape wheel, and balance staff are supported on three potances mounted on the inside of the top plate. When assembling the watch these components have to be put in first. They have curious shapes and it is not immediately obvious as to what goes where.

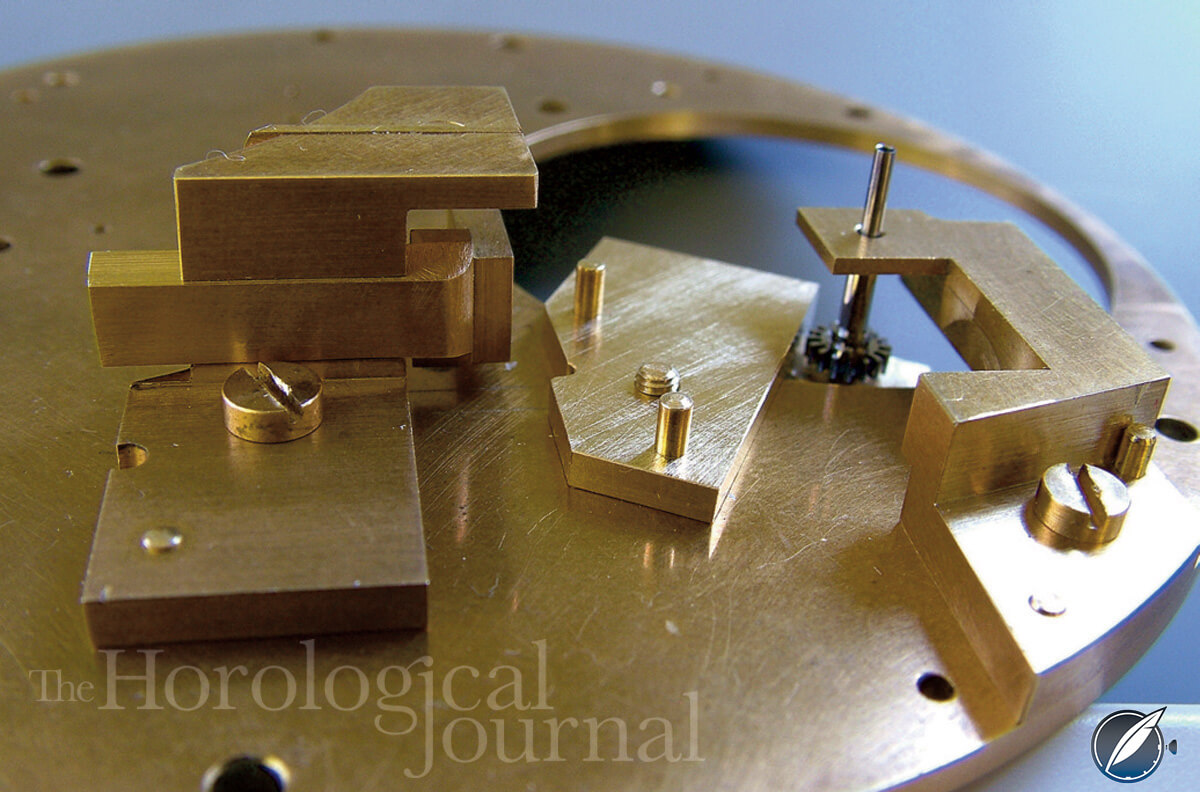

Potances in the rough with the hollow fourth wheel pinion in place for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

Remontoir components and contrate wheel (unfinished) for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

The fourth wheel, contrate wheel, and locking wheel had to be cut along with their pinions and the fly. The wheels were cut using a Schaublin 70 lathe with dividing attachment and vertical slide. Derek had made fly cutters and multi-tooth cutters for the wheels based on good close-up photos of the train wheels. We used these as well as some Thornton cutters for the locking, escape and fly pinions. The center distances for the train were established from the diameters of the wheels and pinions and from the CAD model.

The computer model was particularly helpful in establishing the height of the escape pinion axis and its depthing with the contrate wheel. The clearances of the escapement and remontoir components were particularly close in this area and much depended on getting it right.

Once the coordinates were established, the potances and plates were bored for the fourth wheel, locking wheel, and fly jeweling. This work was done on a Hauser jig borer.

Top plate mounted in Hauser jig borer for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

There is a large hole in the bottom plate that provides access to the remontoir assembly. Boring and milling these holes was always somewhat nerve-wracking as, by this stage, both Derek and ourselves had invested so much time in the plates. It was a case of checking everything was well clamped and then measured and checked several times before cutting. We had a satisfying sense of progress each time another wheel was pivoted between the plates. At this stage the pivots were not jeweled and were running in temporary brass bushings.

Jeweling

Jeweling in the second half of the eighteenth century was not common. Harrison’s watch made by John Jefferys and H4 were early examples of extensive jeweling.

While Daniela and I were working through the train, our colleague, Carl Murray, was busy making the jewel holes. Derek had rough ground jewel blanks made with pierced holes but these were not to size. H4 is jeweled from the third wheel onward. The jewels are larger and thicker than those normally available, so they had to be specially made. There are 14 jewel holes and 12 diamond endstones in the watch. The synthetic ruby jewels can be turned with a diamond cutter and the doming, sinks, and holes were polished with various grades of diamond paste on copper polishers. More detail on this phase of the work can be seen in the account given at the Derek Pratt Memorial Seminar as mentioned earlier.

The upper third wheel and balance jeweling is conventional, with the jewel being rubbed into a brass setting and a diamond endstone mounted in a steel setting and screwed to the bridge. The contrate wheel, fourth wheel, locking wheel, escape wheel, and fly all have their jewel holes mounted in brass settings with dovetails cut into them. The dovetails each accept a corresponding wedge that holds the diamond endstone.

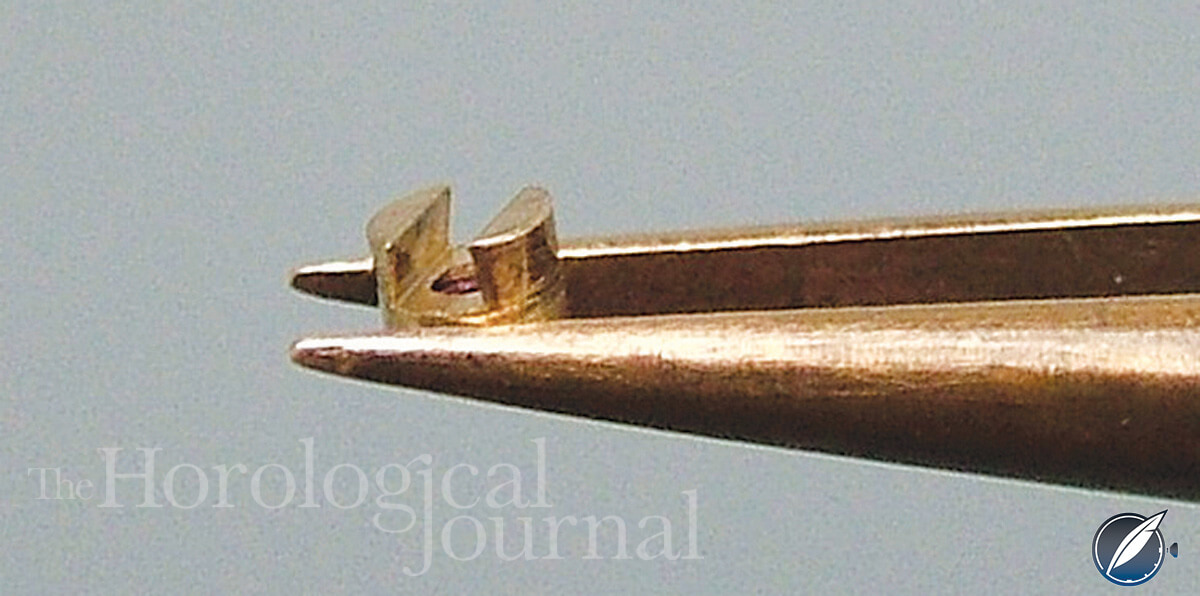

Jewel hole in dovetail setting for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

Jewel slid into dovetailed endpiece for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

Cutters made to produce jeweling dovetails

Close-up of cutter for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

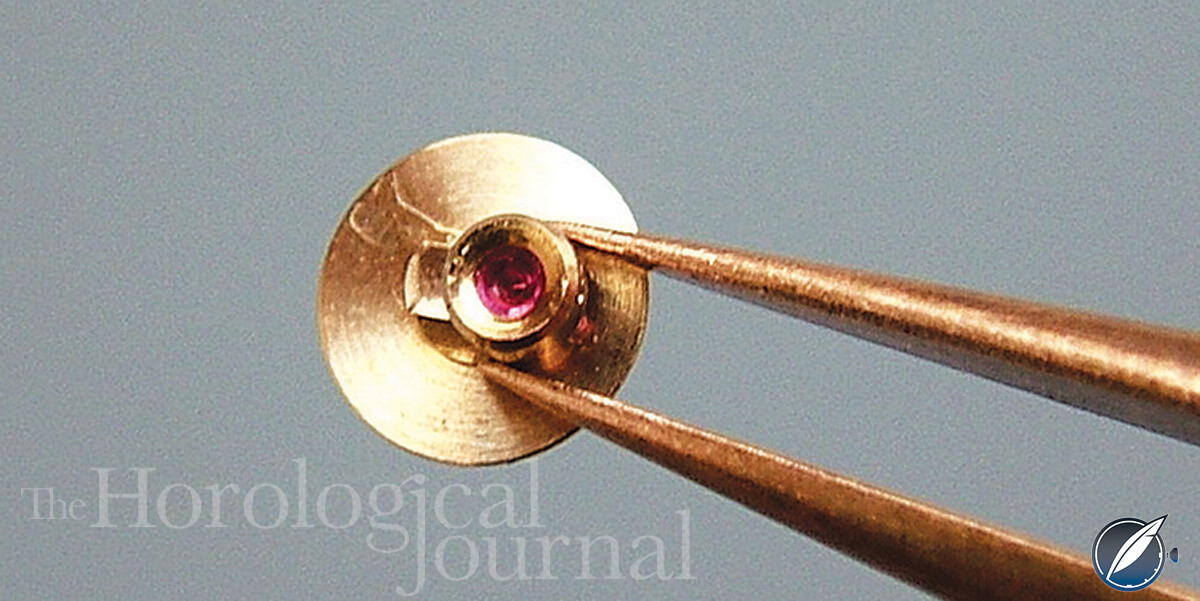

Balance potance assembly used for for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

The image above shows the balance potance which contains four dovetail slides. The lower balance endpiece slide can be seen on the top of the potance and the front escape jeweling is also shown.

Front escape jewel hole with its diamond endstone for Derek Pratt’s H4 reconstruction (photo courtesy British Horological Journal)

The image above shows the front escape jeweling with the endpiece slid out and turned over to show the diamond endpiece. The large dovetail in the side of the balance potance is for adjusting the depth of the escape wheel engagement with the pallets and the front escape setting is in a slide that allows the escape wheel to be centered on the balance axis. Slides within slides! This is like the arrangement in a conventional verge escapement and is the means of equalizing the drop onto each pallet.

Some of the jeweling is very small, for instance the escape counter-potance jewel hole is only 0.8 mm outside diameter.

Escape counter-potance jewel hole and slide; the cut-out in the cylindrical counter-potance is to clear the fourth wheel arbor (photo courtesy British Horological Journal)

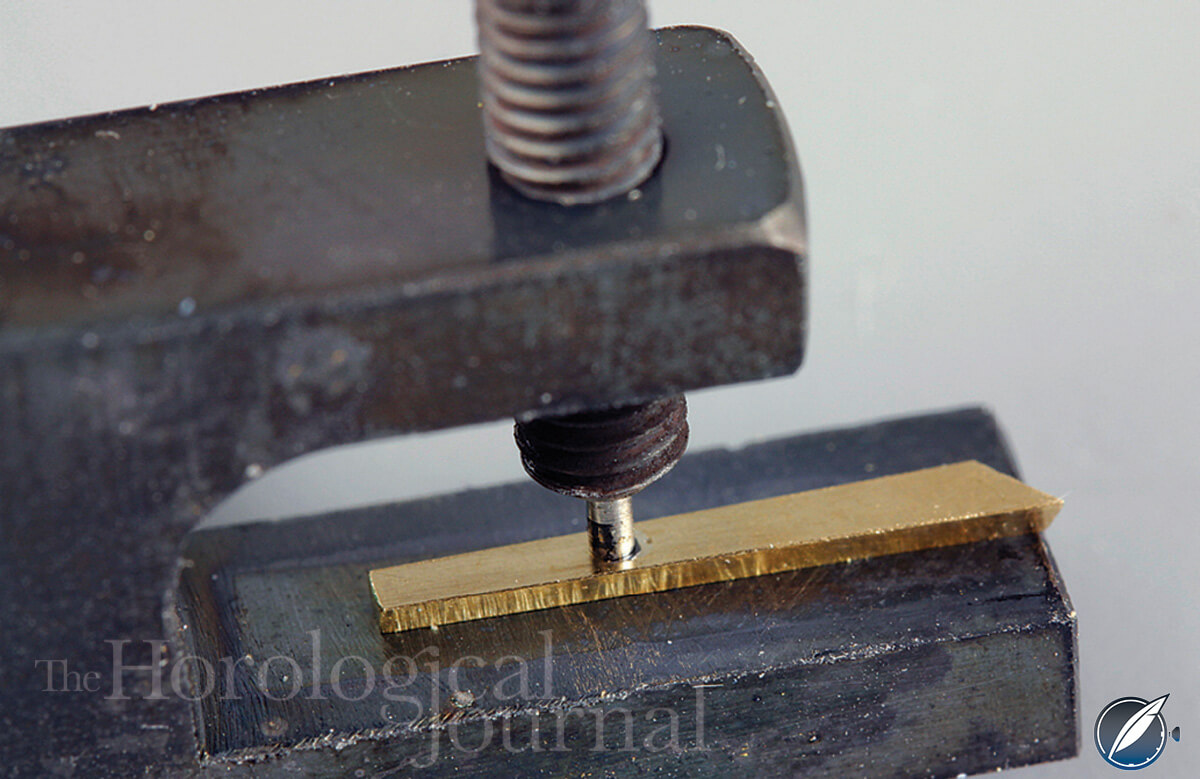

The diamond endstones were silver-soldered into their brass dovetail holders using a miniature “G” clamp to hold them in place while soldering.

Clamping diamond in brass endpiece whilst soldering (photo courtesy British Horological Journal)

The diamonds were taken from scrapped jewelry, using flat polished surfaces for the pivot bearing and grinding the sides of the diamond to fit into the dovetail wedge. Most of the endpieces were small, between 0.6 and 0.8 mm in diameter.

The dovetailed settings are a strange and awkward arrangement for jeweling, and Larcum Kendall (see Larcum Kendell And K1: The Greatest Watchmaker And Watch You Have (Probably) Never Heard Of) abandoned this in his K1 copy, using instead conventional settings and endpieces held in place by screws.

Diamond pallets

Derek had made two diamond pallets for his H4 and he said that at least one more would need to be made. The first pallet Derek produced was well finished but slightly under size on the radius of the back of the pallet, while the second was near perfect dimensionally and with a fine polish. My colleague Carl Murray took on the challenge of making diamond pallets and he will describe how he produced these in the next installment.

You can buy a DVD of the film about Derek Pratt’s H4 reconstruction at http://www.bdvideos.co.uk/site/shop/horology/a-detailed-study-of-h4/ (all profits go to the charity Prostate Cancer UK).

For more information, please visit www.frodsham.com/harrison-h4 and you may enjoy www.amazon.com/Longitude-Genius-Greatest-Scientific-Problem.

You may also enjoy reading the rest of this three-part series:

2/3 Making The Diamond Pallets For Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronometer

3/3 Making The Escapement, Remontoir, And Timing For Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronometer

and The Life And Times Of Legendary Independent Watchmaker Derek Pratt.

Trackbacks & Pingbacks

-

[…] You may also enjoy: Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronom… […]

-

[…] You might also be interested in reading the three-part series: Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronom…. […]

-

[…] about Derek Pratt please see The Life And Times Of Legendary Independent Watchmaker Derek Pratt, Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronom…, and Making The Diamond Pallets For Derek Pratt’s Reconstruction Of John Harrison‘s H4, The […]

-

[…] Life And Times Of Legendary Independent Watchmaker Derek Pratt and for part 1 in this series click Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronom…. We will publish part 3 on January 11, […]

-

[…] You may also enjoy Derek Pratt’s Reconstruction Of John Harrison‘s H4, The World’s First Precision Marine Chronom… […]

Leave a Reply

Want to join the discussion?Feel free to contribute!

Fantastic article Q&P.

I was lucky enough to see the Pratt/Frodsham replica movement in person in september when it was shown in a Sydney Maritime Museum in Australia.

Truly magnificent!

Derek was a genius.

Fantastic reading – looking forward to the next installments!

After one year, I have just grasped the workings of the regular , simple verge.

This is in another league! Not to mention Pratt’s own inventions – genius.